Production technology of high elastic water-absorbing and quick-drying smooth fabric

A water-absorbing, quick-drying, production process technology, applied in knitting, textiles, papermaking, weft knitting, etc., can solve the problems of unstable yarn feeding angle of spandex yarn, high equipment investment cost, waste of garment production, etc., and achieve water-absorbing and quick-drying The effect of excellent performance, saving the cost of introduction, and reducing the difficulty of debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

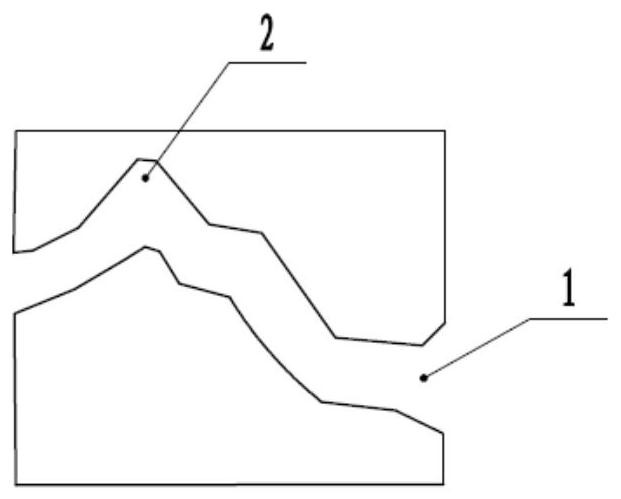

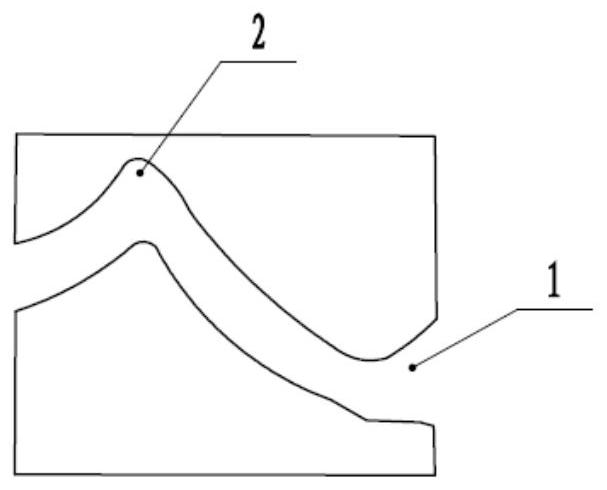

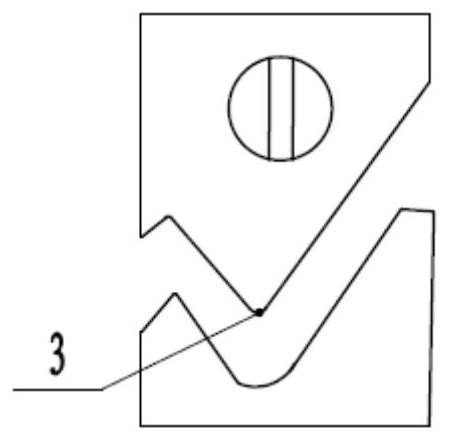

[0024] This embodiment provides a production process for high-elastic water-absorbing and quick-drying smooth fabrics. The existing large circular knitting machines are improved. The main improvements are: (1) shorten the needle latch by 0.38 mm, and tilt the needle hook back by 15 mm. ", to reduce the loop-off motion and ensure the stable weaving of spandex. (2) Change the needle-starting trajectory of the needle cylinder needle cam: the needle-triggered trajectory of the traditional cylinder needle needle cam is a segmented buffer mode, such as figure 1 As shown, the lowest point on the right side is needle starting point 1, a platform is set between needle starting point 1 and highest point 2, and the running track of the needle is segmented. The improved needle needle triangle such as figure 2 As shown, there is a gradual and smooth transition between the starting point 1 and the highest point 2, and the needle’s running track is a gradual and direct needle-off loop, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com