Deep-dyed elastic fabric and production method thereof

An elastic fabric, deep dyeing technology, applied to fabrics, fabrics, textiles and other directions with resilience performance, can solve the technical difficulty of dyeing and other problems, and achieve the effect of good deep dyeing effect, good water absorption and quick drying, and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

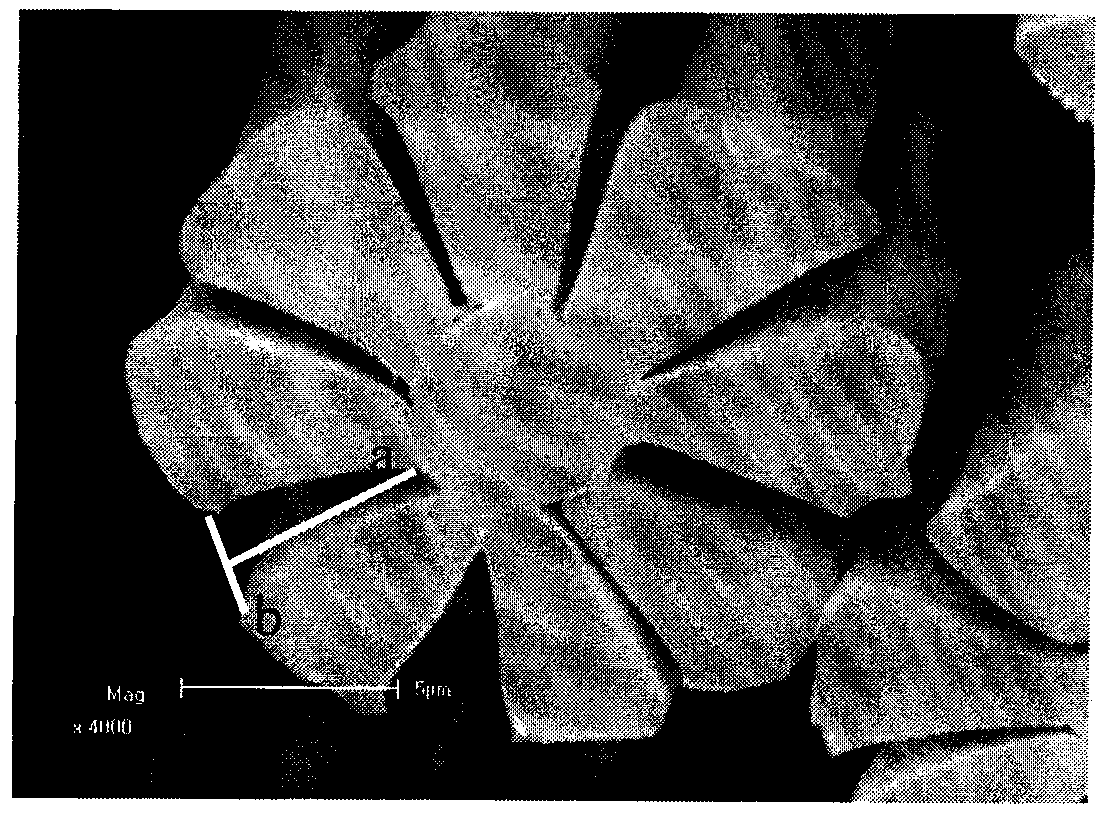

[0024] Select 100D-48f-common PET / soluble PET composite fiber 96% by weight, 30D spandex 4% by weight, use a 28G single-jersey knitting machine with a density of 46w / inch×84c / inch to form a blank, and then reduce the above blank , to obtain a blank containing multi-lobed special-shaped section PET yarns; finally, the obtained blank is subjected to post-dyeing treatment to obtain the deep-dyed elastic fabric of the present invention.

[0025] Among them, weight reduction-post-dyeing processing engineering: relaxation and scouring→intermediate setting→alkali weight reduction→disperse dyeing (including reduction cleaning)→hot air stenter setting

[0026] (1) Relaxation and scouring: The machine has 4 tanks in total, the temperatures of which are 40°C, 40°C, 60°C, and 90°C, the speed: 20m / min, and the residence time: 15-20 seconds.

[0027] (2) Intermediate shaping: temperature: 190 degrees, speed: 20m / min, overfeed: +55, the falling method is shaken, and the density is 45w / in×85c...

Embodiment 2

[0033] 60% by weight of 75D-48f-common PET / soluble PET composite fiber is used as warp yarn, 40% by weight of 50D-48f-PET / PTT yarn is used as weft yarn to form a blank, and then the above blank is reduced to obtain a multi-lobed special-shaped The white blank of cross-section PET yarn; finally, the white blank obtained is subjected to post-dyeing treatment to obtain the deep dyed elastic fabric of the present invention.

[0034] Among them, weight reduction-post-dyeing processing engineering: gray cloth setting → relaxation and scouring → alkali reduction → disperse dye dyeing (including reduction cleaning) → hot air stenter setting

[0035] (1) Gray cloth shaping: temperature 140°C, speed: 50m / min.

[0036] (2) Relaxation and scouring: the average temperature of the machine is 100°C, and the speed is 70m / min.

[0037] (3) Alkali weight reduction treatment: the weight reduction in the cylinder is 110°C×30min, and the final weight reduction rate reaches 15% (the fiber reaches ...

Embodiment 3

[0042] Select 55% by weight of 100D-24f-common PET / soluble PET composite fiber as warp yarn, and 45% by weight of 55D-24f-PBT yarn as weft yarn to form a blank, and then reduce the weight of the above-mentioned blank to obtain PET with multi-lobed special-shaped cross-section. The white blank of yarn; finally the white blank obtained is processed after dyeing to obtain the deep dyed elastic fabric of the present invention.

[0043] Among them, weight reduction-post-dyeing processing engineering: relaxation and scouring→alkali weight reduction→disperse dyeing (including reduction cleaning)→hot air stenter setting

[0044] (1) Relaxation and scouring: the average temperature of the machine is 100°C, and the speed is 70m / min.

[0045] (2) Alkali weight reduction treatment: in-cylinder weight reduction 110°C×30min, the final weight reduction rate reaches 19% (the fiber reaches the best fiber-opening state).

[0046] (3) Dyeing: Maximum temperature: 120°C×30min, heating rate: 1.0°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com