A quick loading and unloading split fixture for fatigue test

A fatigue test, split-type technology, applied in measuring devices, analytical materials, instruments, etc., can solve problems such as poor clamping accuracy and consistency, affecting test accuracy, and inconsistent design loads, achieving high clamping and disassembly efficiency, improving The effect of test accuracy, convenience and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

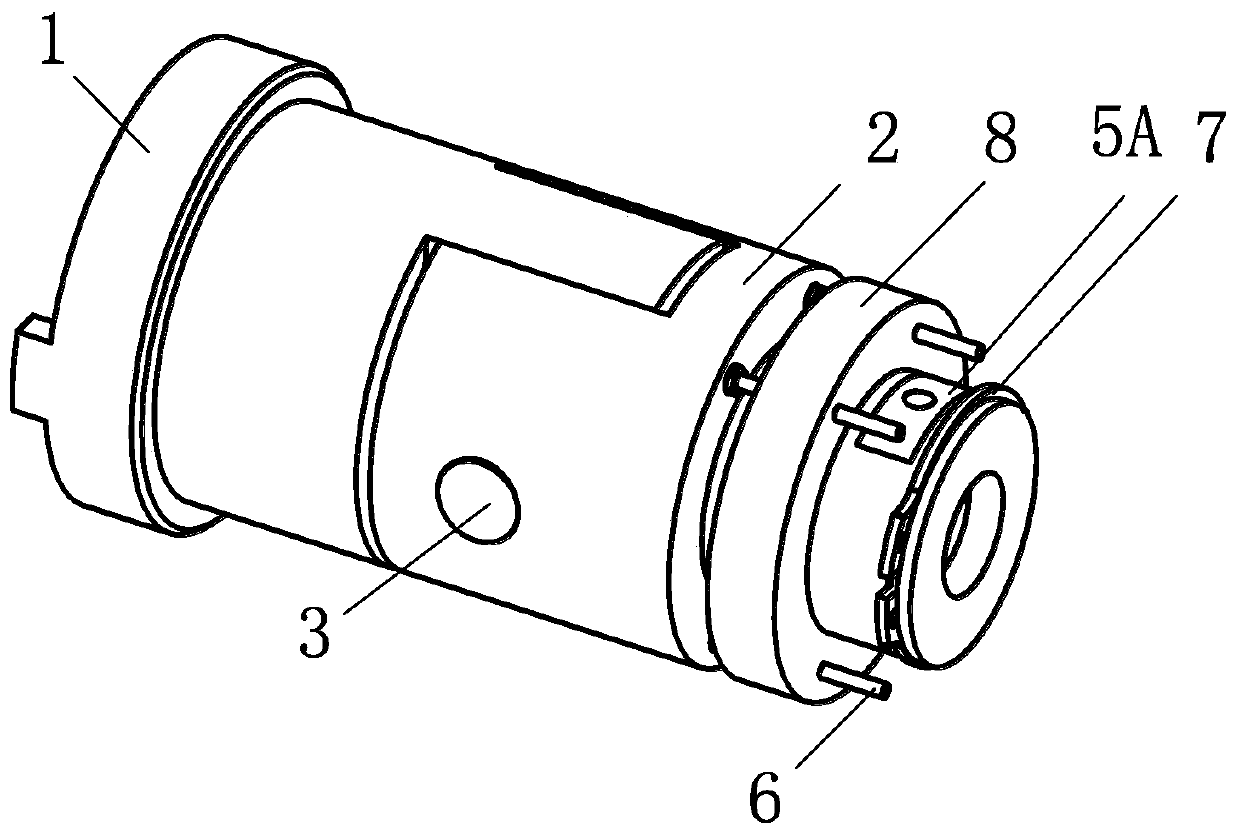

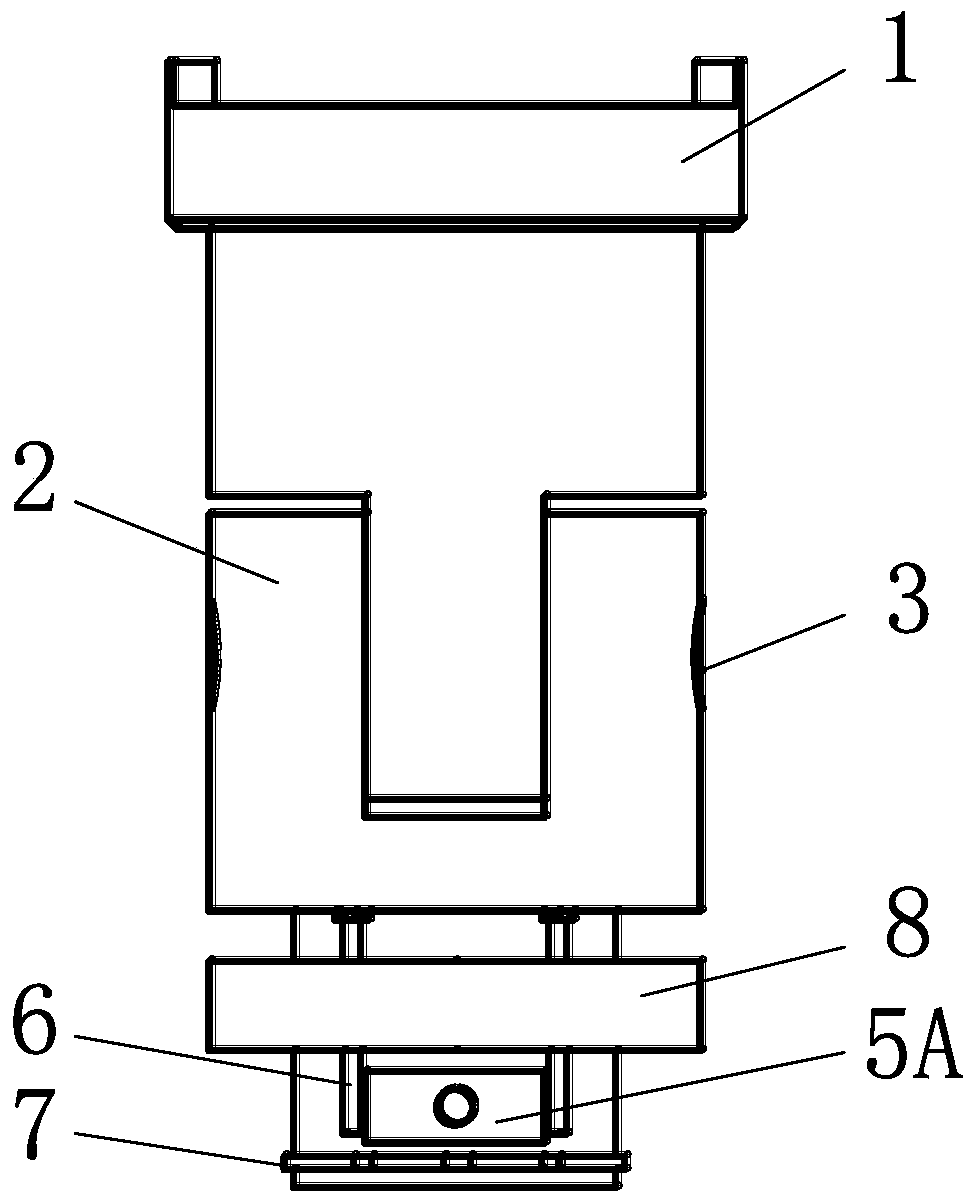

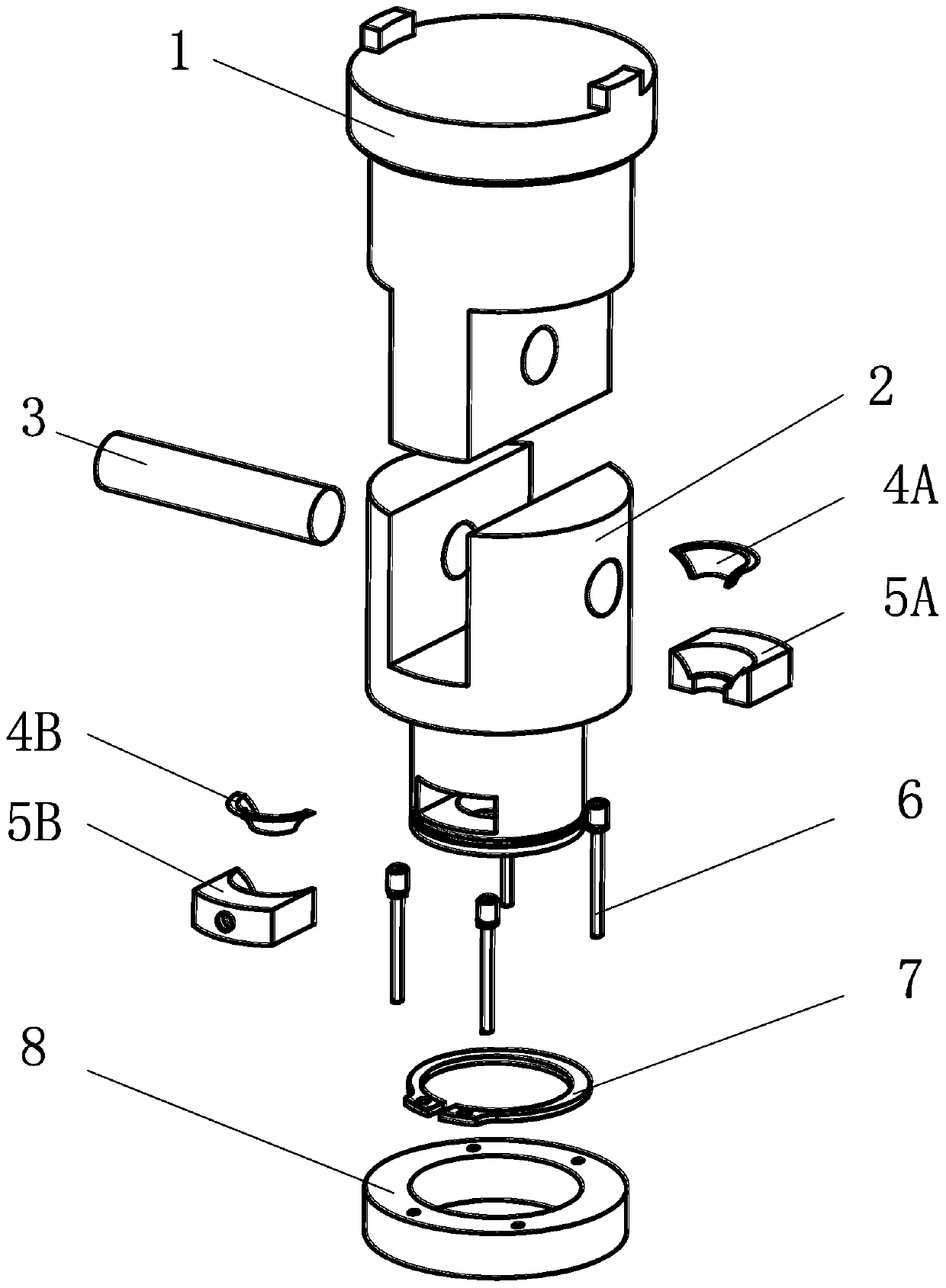

[0024] The operation mode of the fixture used in the fatigue life test of the test piece of the present invention will be further explained in conjunction with the accompanying drawings:

[0025] The first step: Use the pin 3 to connect the upper clamp body 1 and the lower clamp body 2; screw the guide rod 6 into the threaded hole at the bottom of the lower clamp body 2 to complete the guide rod installation; install the collar 8 into the lower clamp body 2 Lower part; insert the retaining ring 7 into the lower groove of the lower clamp body 2; use glue to paste the left gasket 4A on the left support plate 5A, and the right gasket 4B on the right support plate 5B; push the collar 8, Expose the radial hole at the lower part of the lower clamp body 8, insert the left and right spacers into the radial hole from both sides. Complete the installation of specific components.

[0026] Step 2: Install the concrete components of the upper and lower clamps to the beam and base of the fatigu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com