Mullion-transom structure

A technology of beams and mullions, applied to building components, building structures, roofs, etc., can solve the problems that the closed design of heat insulation cannot be adjusted, and the heat insulation is limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

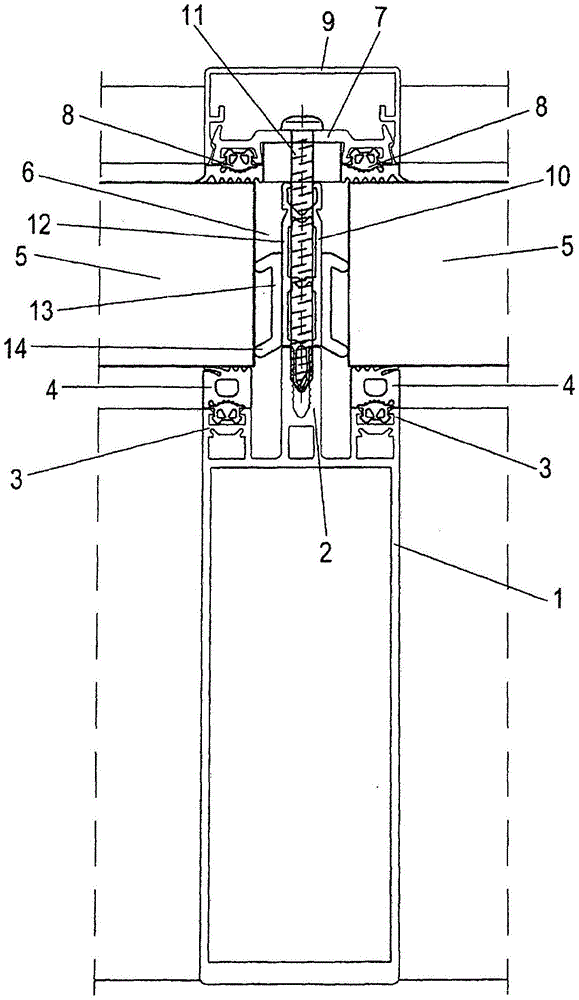

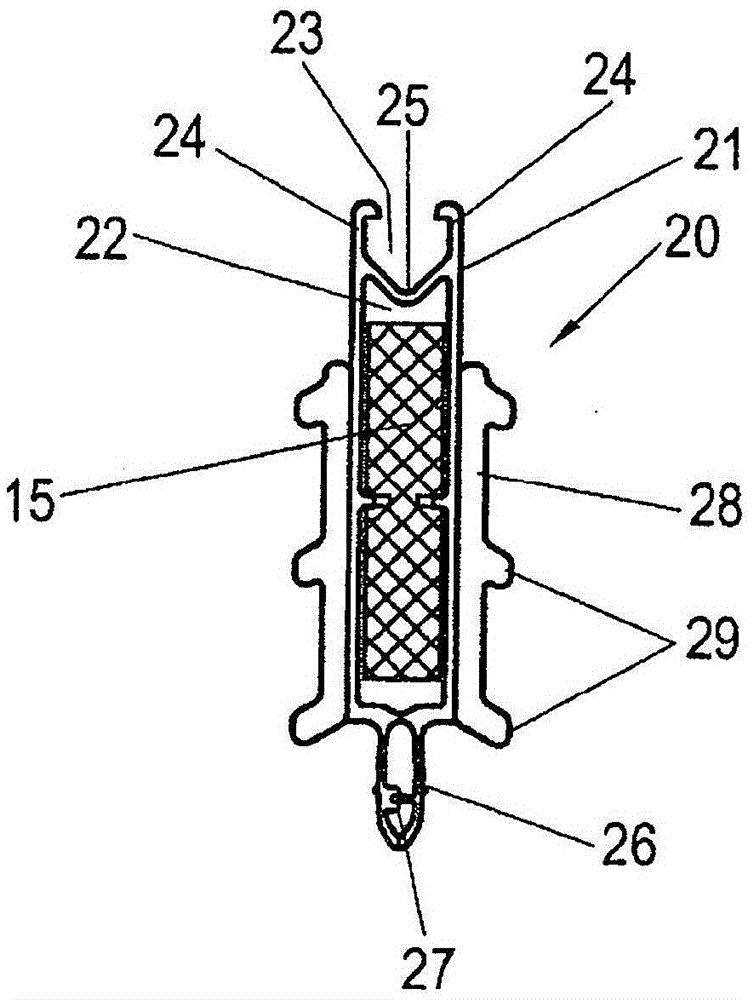

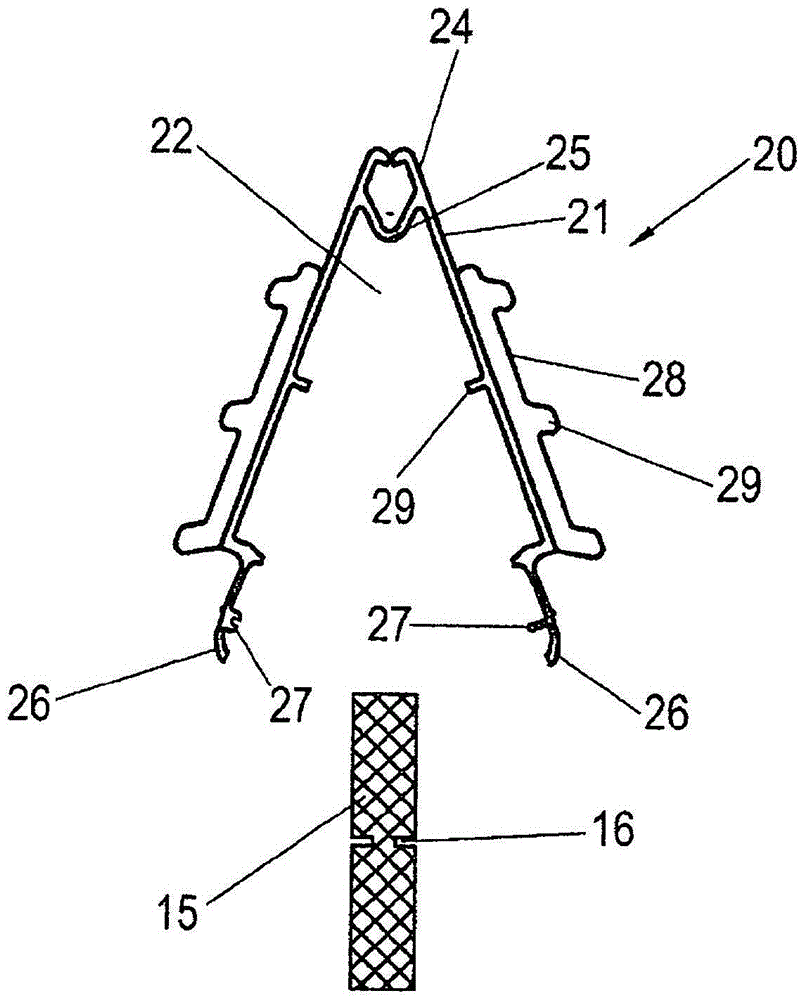

[0030] The mullion beam structure comprises a support profile 1 which can be designed as a mullion or beam, wherein thread grooves 2 are provided on the outside. On both sides of the threaded groove 2 are formed holders 3 for a sealing strip 4 which rests on the edge side against a filling element 5 , in particular an insulating glass pane. A compression strip 7 is provided for fastening the filling element 5 , which is arranged on the outer side of the filling element 5 by means of a seal 8 . The filling element 5 is clamped between the sealing device 8 and the sealing strip 4 at the edges, respectively. The pressure strip 7 is fixed here by a plurality of screws 11 which are arranged in the recess 6 between the end faces of the filling element 5 and engage in the threaded groove 2 .

[0031] An insulating strip 10 is also provided on the end face of the filling element 5 , which is penetrated by a screw 11 and has a shaped body 12 . An insulating strip 13 made of a materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com