wheel assembly

An assembly and wheel technology, applied in the field of wheel assembly, can solve the problems of reduced strength and durability, and achieve the effect of improving strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

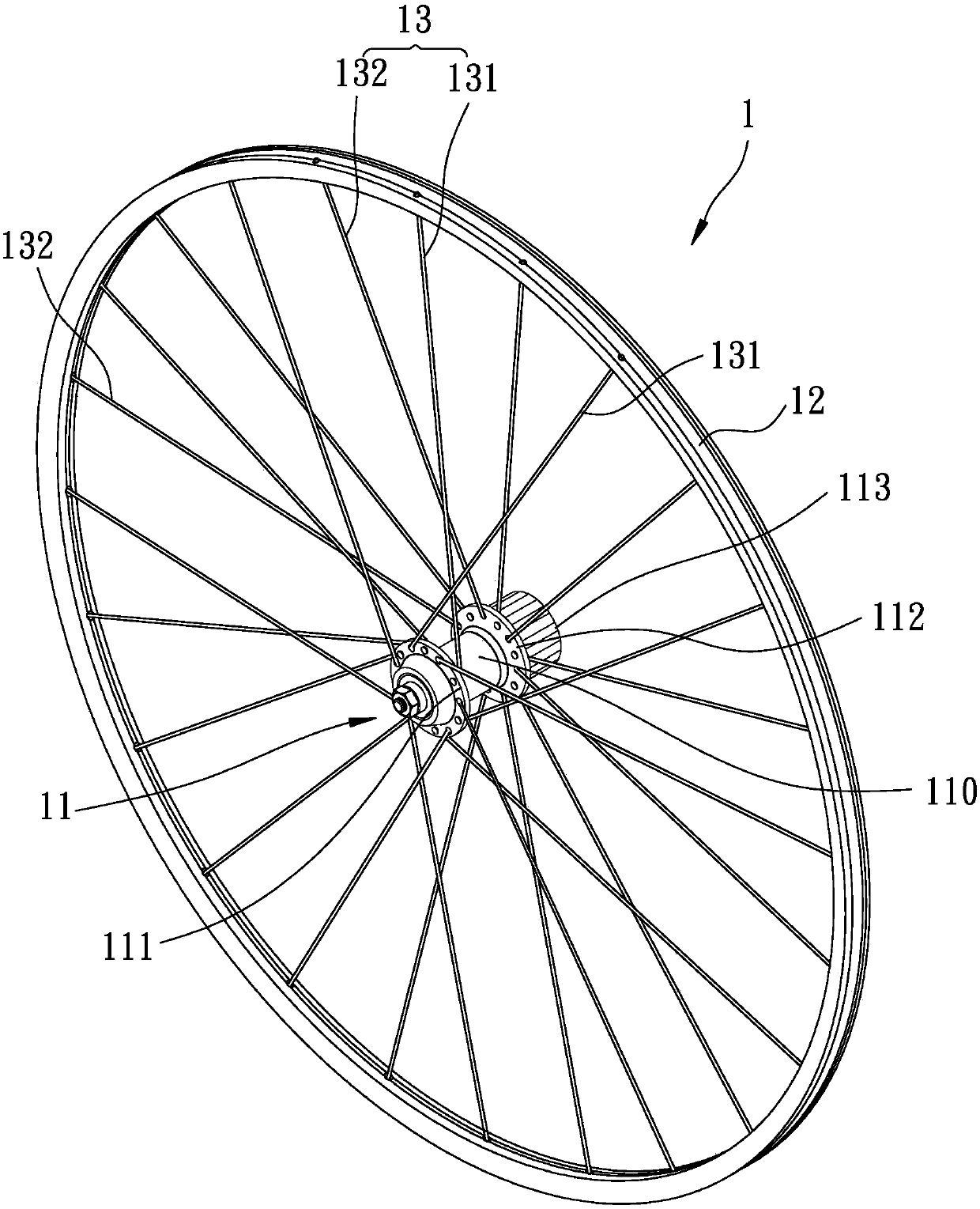

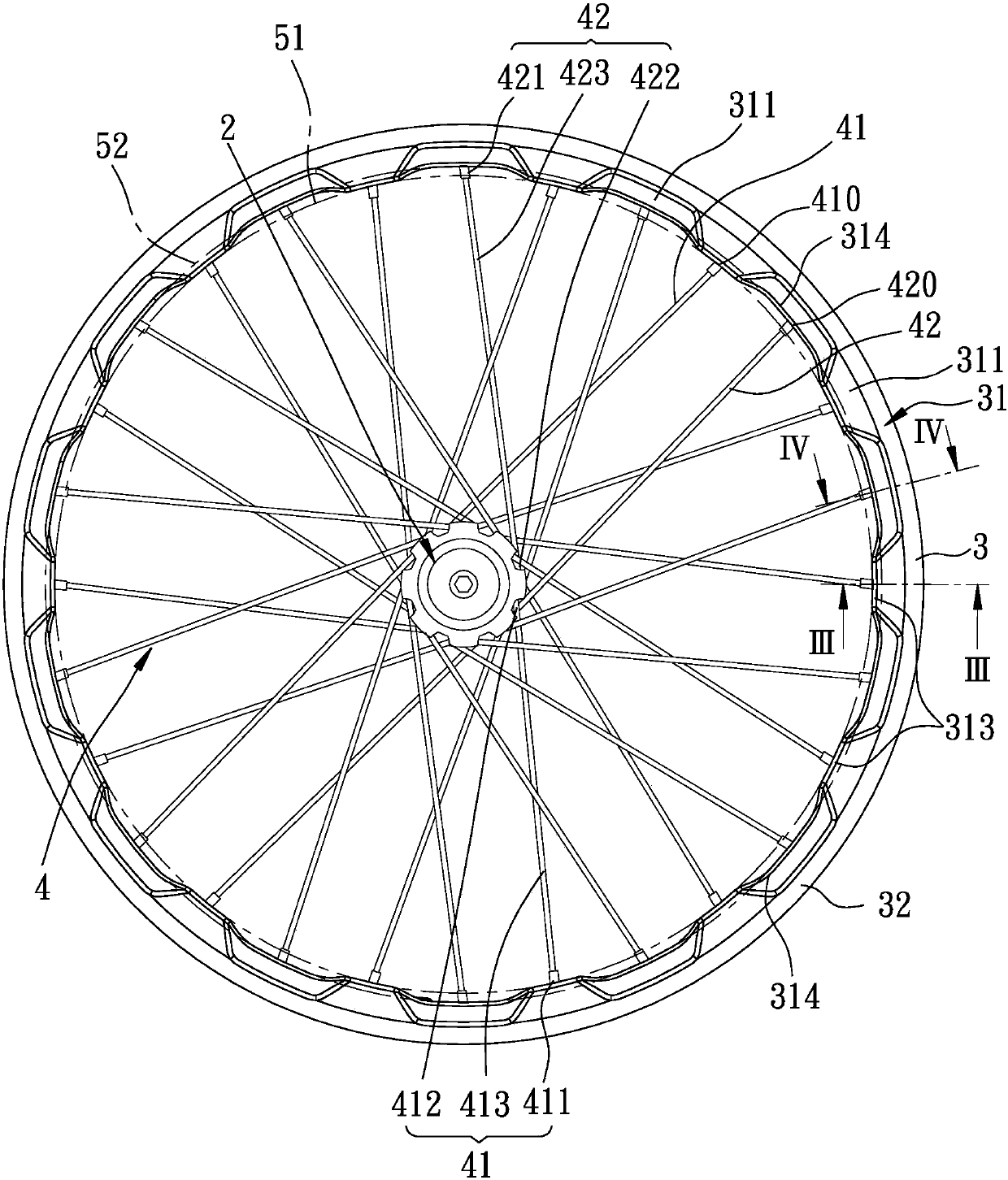

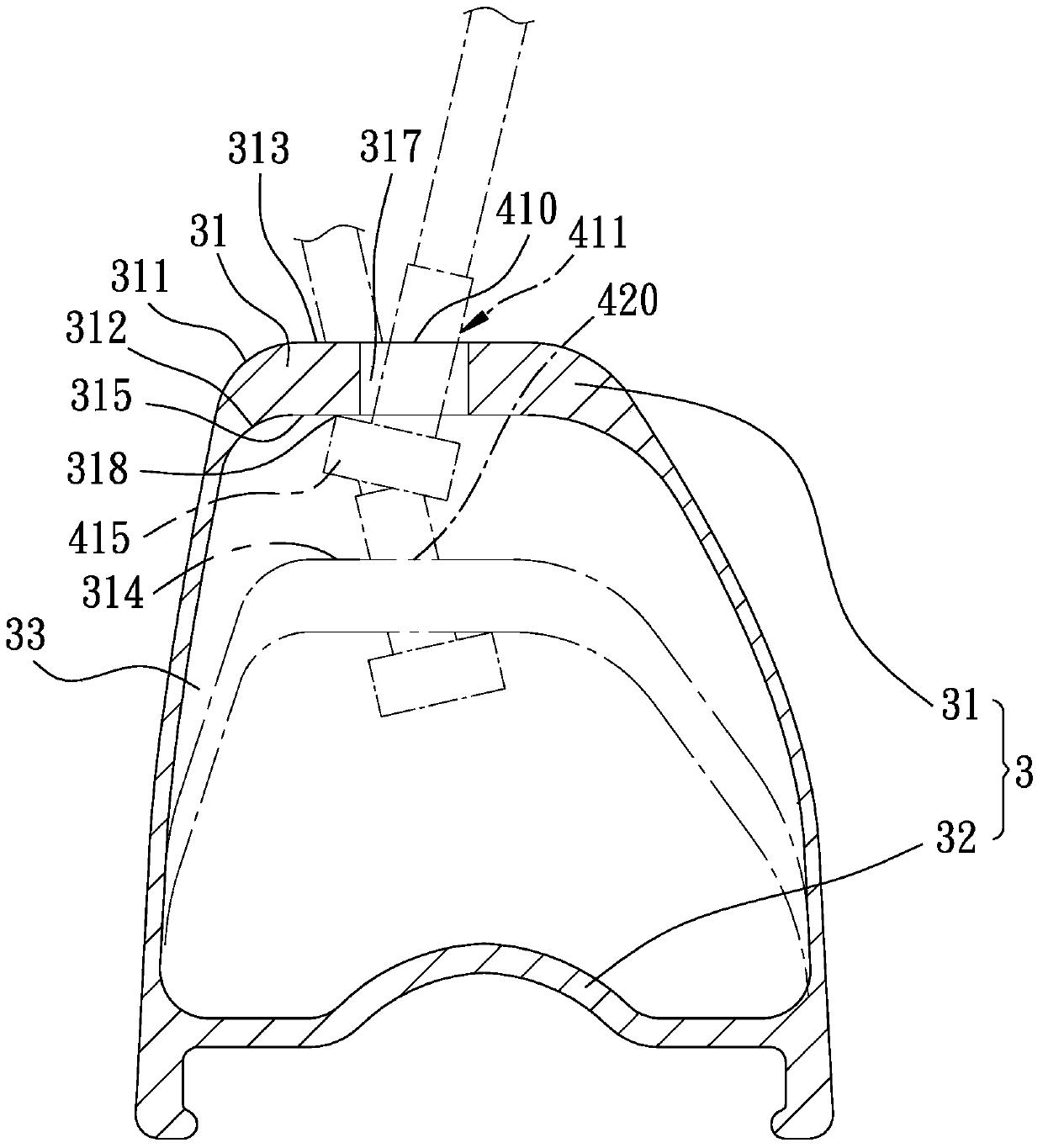

[0031] refer to figure 2 and Figure 5 , the wheel assembly according to the present invention includes a central hub 2, an outer rim 3 including a spoke bed wall 31, and a spoke unit 4 including a plurality of first spokes 41 and a plurality of second spokes 42. The first spokes 41 and the second spokes 42 respectively extend between the outer rim 3 and the central hub 2 . Each first spoke 41 has a first end 411 formed with a first spoke bed connecting portion 410, a second end 412 opposite to the first end 411 and connected to the central hub 2, and a second end 412 extending from the first spoke bed connecting portion 410. The radial portion 413 between the one end 411 and the second end 412 . The first end 411 of each first spoke 41 is connected to the spoke bed wall 31 with its first spoke bed connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com