Cutting elements, related methods of forming a cutting element, and related earth-boring tools

A cutting element and cutting surface technology, which is applied in the manufacture of tools, earthwork drilling, drill bits, etc., can solve the problems of uneven leaching depth of PDC, defective cutting elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

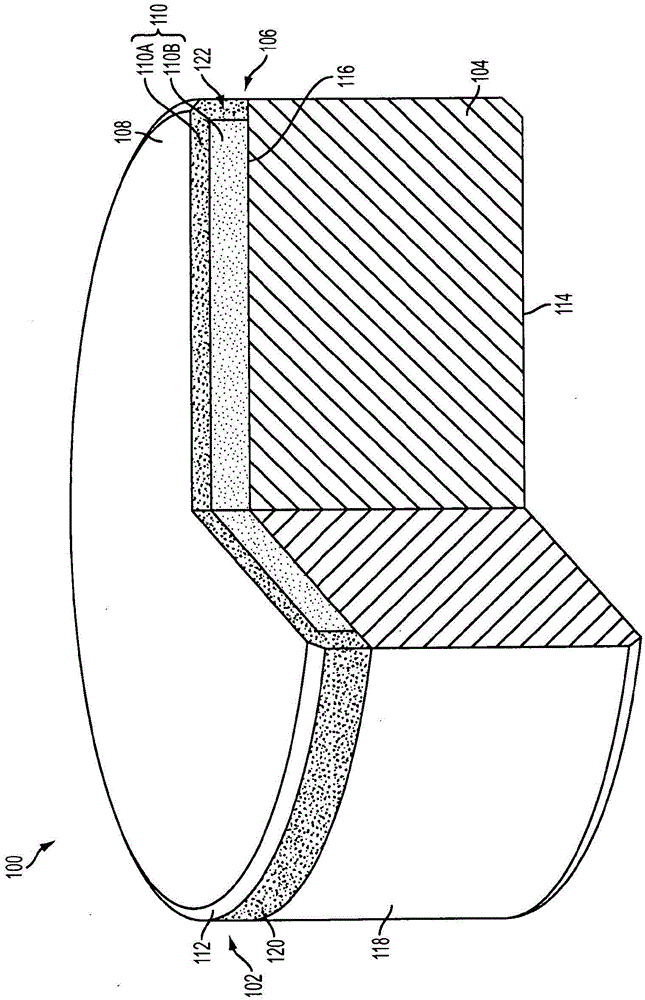

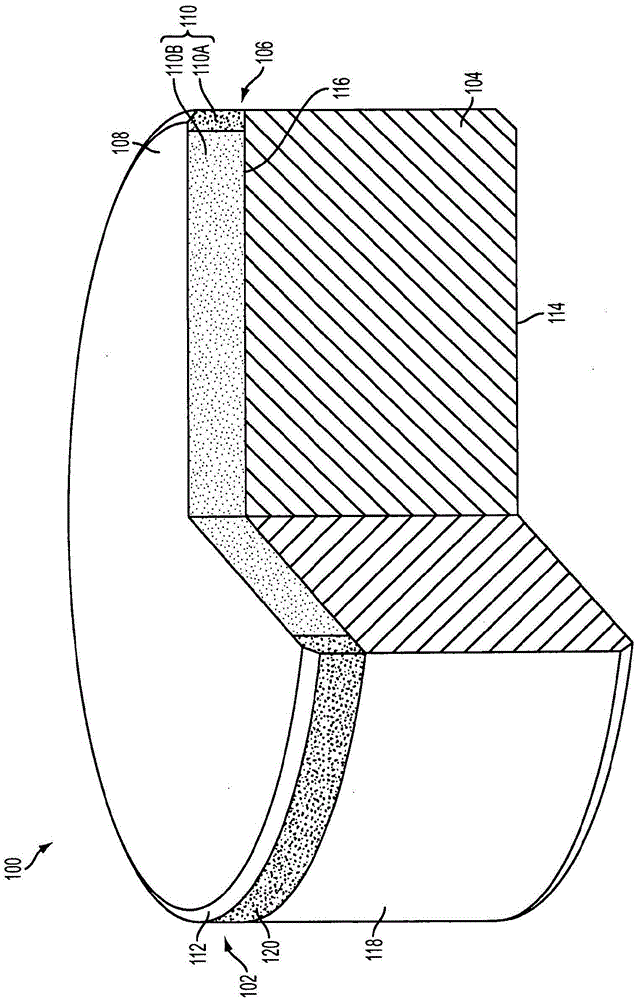

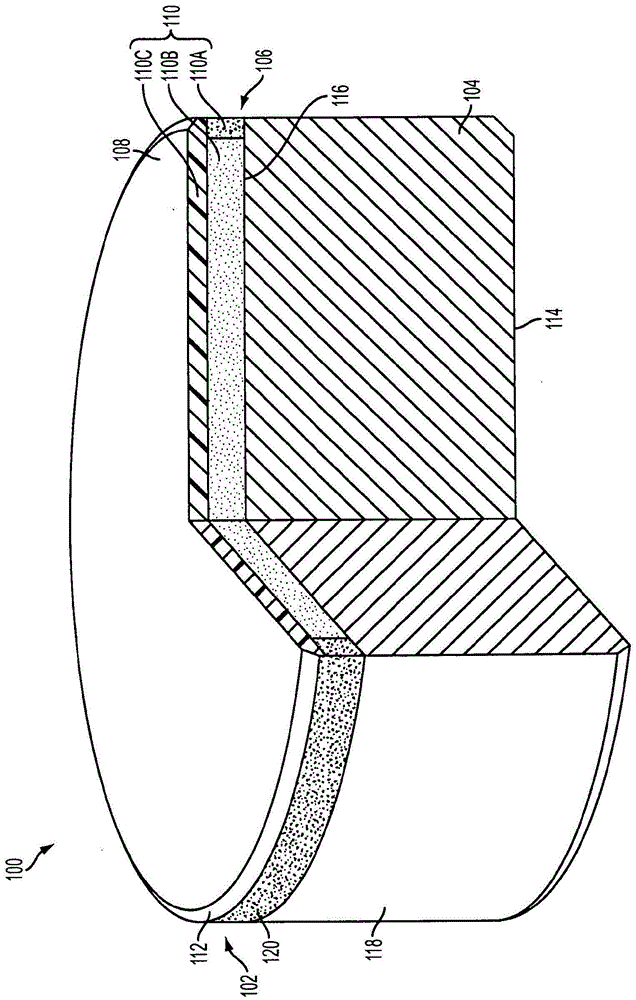

[0019] Cutting elements for drilling tools are described, methods for forming the cutting elements and drilling tools are also described. In some embodiments, the cutting element includes a polycrystalline compact attached to an end of a support matrix. The polycrystalline compact includes a first region extending from the support matrix and laterally surrounding a second region. The first region of the polycrystalline compact is less permeable than the second region of the polycrystalline compact. During the leaching process, the structural size (i.e., shape) and permeability of the first region can facilitate improved leaching velocity uniformity and leaching depth uniformity (compared to many conventional polycrystalline compacts), thereby, compared to many Compared with traditional cutting elements and tools, there will be less damage to cutting elements and defects on cutting elements, which will reduce manufacturing waste and improve performance and reliability.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com