High-frequency noise reduction restraining and damping wheel containing slits

A technology of constraining damping and wheels, which is applied to wheels, wheels characterized by rail running parts, vehicle parts, etc., can solve the problems that the effect of vibration and noise reduction needs to be improved, and local damage needs to be replaced as a whole, so as to achieve rich vibration modes , Improve shear energy consumption and suppress vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

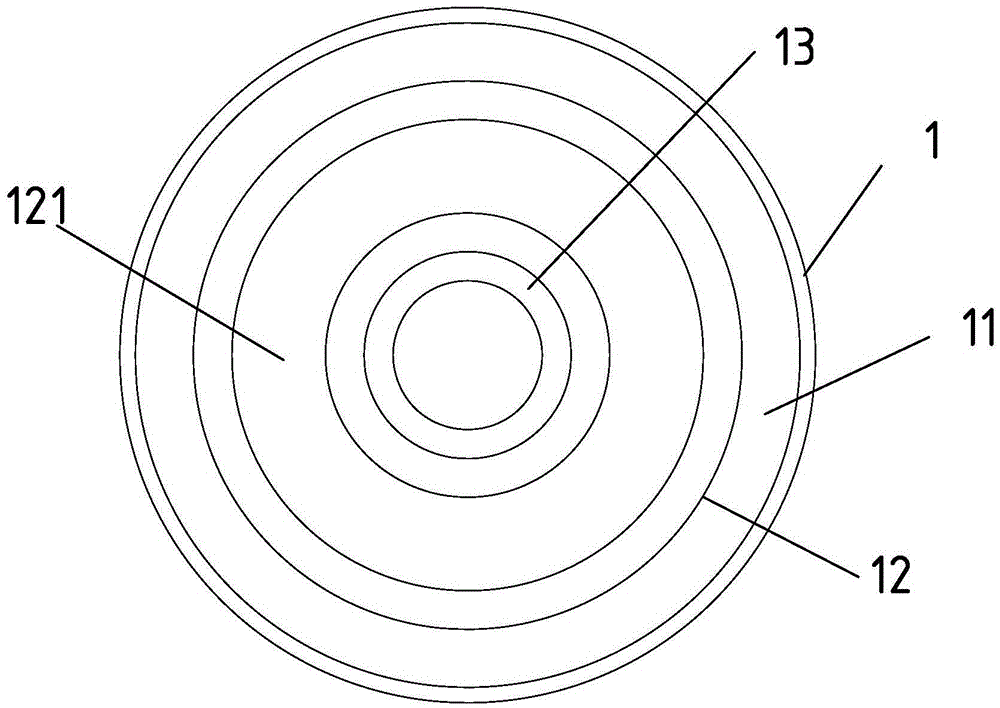

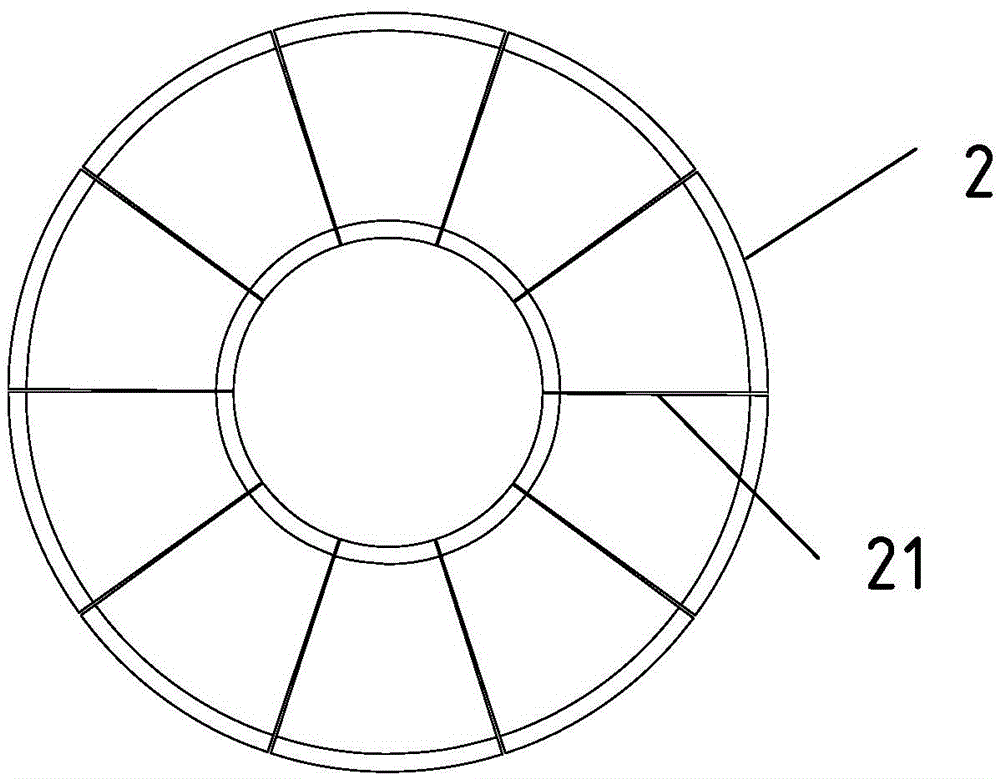

[0035] Such as Figure 1-7 , Figure 9 with Figure 10 As shown, a high-frequency noise-reducing constrained damping wheel with slits includes the standard wheel 1 and the constrained damping layer located outside the standard wheel, and the constrained damping layer includes a bonded damping layer 2 and a constraining layer 3, the constraining layer 3 is bonded to the standard wheel 1 through the damping layer 2, the damping layer 2 has 10 slits I21, and the constraining layer 3 has slits I21 Corresponding slot II31.

[0036] Described standard wheel 1 comprises wheel rim 11, wheel spoke 12 and wheel hub 13, and both sides of described wheel spoke 12 all have the annular groove 121 that takes the axis of described standard wheel 1 as axis, and the groove bottom 1211 of described annular groove 121 Perpendicular to the axis of the standard wheel 1, both sides of the groove bottom 1211 have concave arc groove walls 1212, the inner diameter of the annular groove 121 is equal ...

Embodiment 2

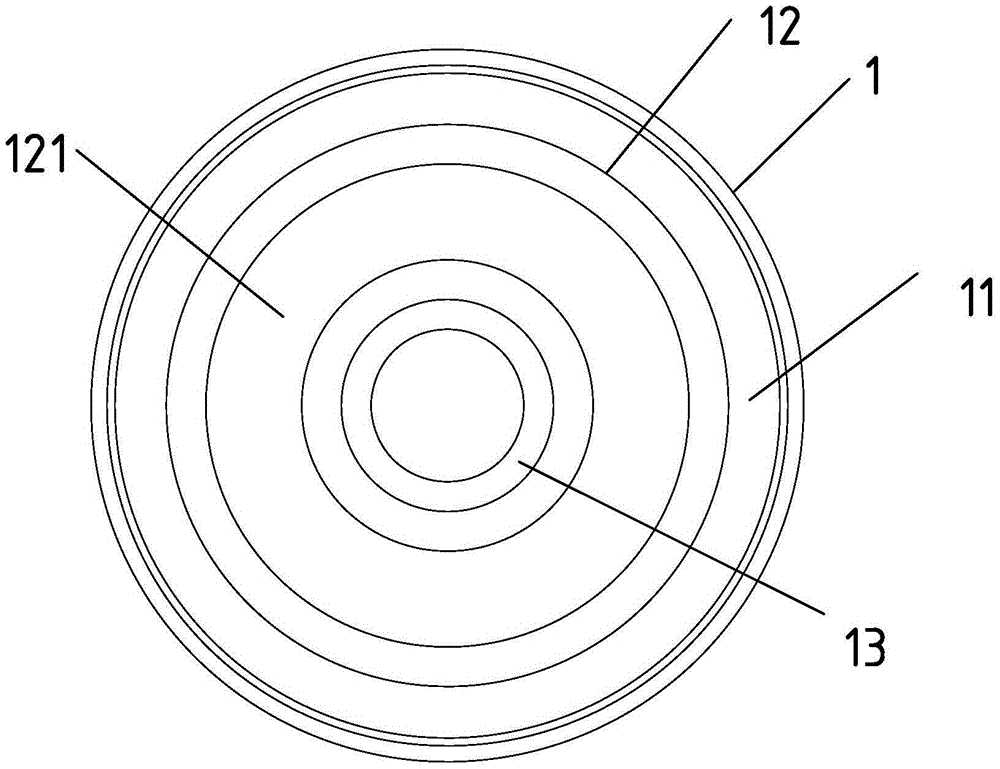

[0045] Such as Figure 1-6 , Figure 8 , Figure 9 , Figure 11As shown, a high-frequency noise-reducing constrained damping wheel with slits includes the standard wheel and the constrained damping layers respectively located on both sides of the standard wheel, and the constrained damping layer includes a bonded damping layer Layer 2 and constraining layer 3, the constraining layer 3 is bonded to the standard wheel 1 through the damping layer 2, the damping layer 2 has 10 slots I21, and the constraining layer 3 has Ⅰ21 corresponds to the slit Ⅱ31.

[0046] Described standard wheel 1 comprises wheel rim 11, wheel spoke 12 and wheel hub 13, and both sides of described wheel spoke 12 all have the annular groove 121 that takes the axis of described standard wheel 1 as axis, and the groove bottom 1211 of described annular groove 121 Perpendicular to the axis of the standard wheel 1, both sides of the groove bottom 1211 have concave arc groove walls 1212, the inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com