Turbocharger core oil extraction device

A turbocharger and oil pumping technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve problems such as inability to meet production needs, poor effect, and high cost, and achieve false positives. No permanent oil leakage problem, low oil mist noise, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

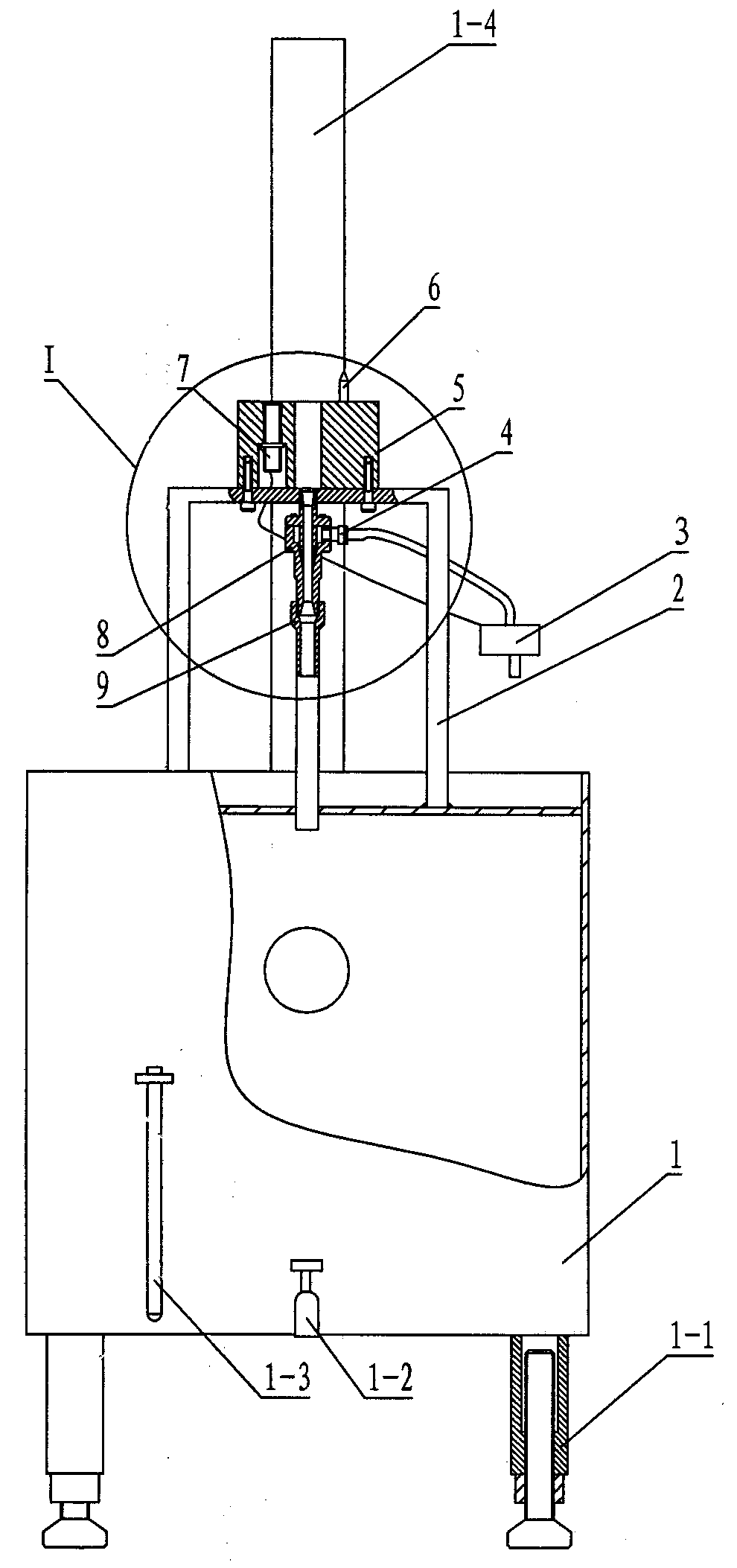

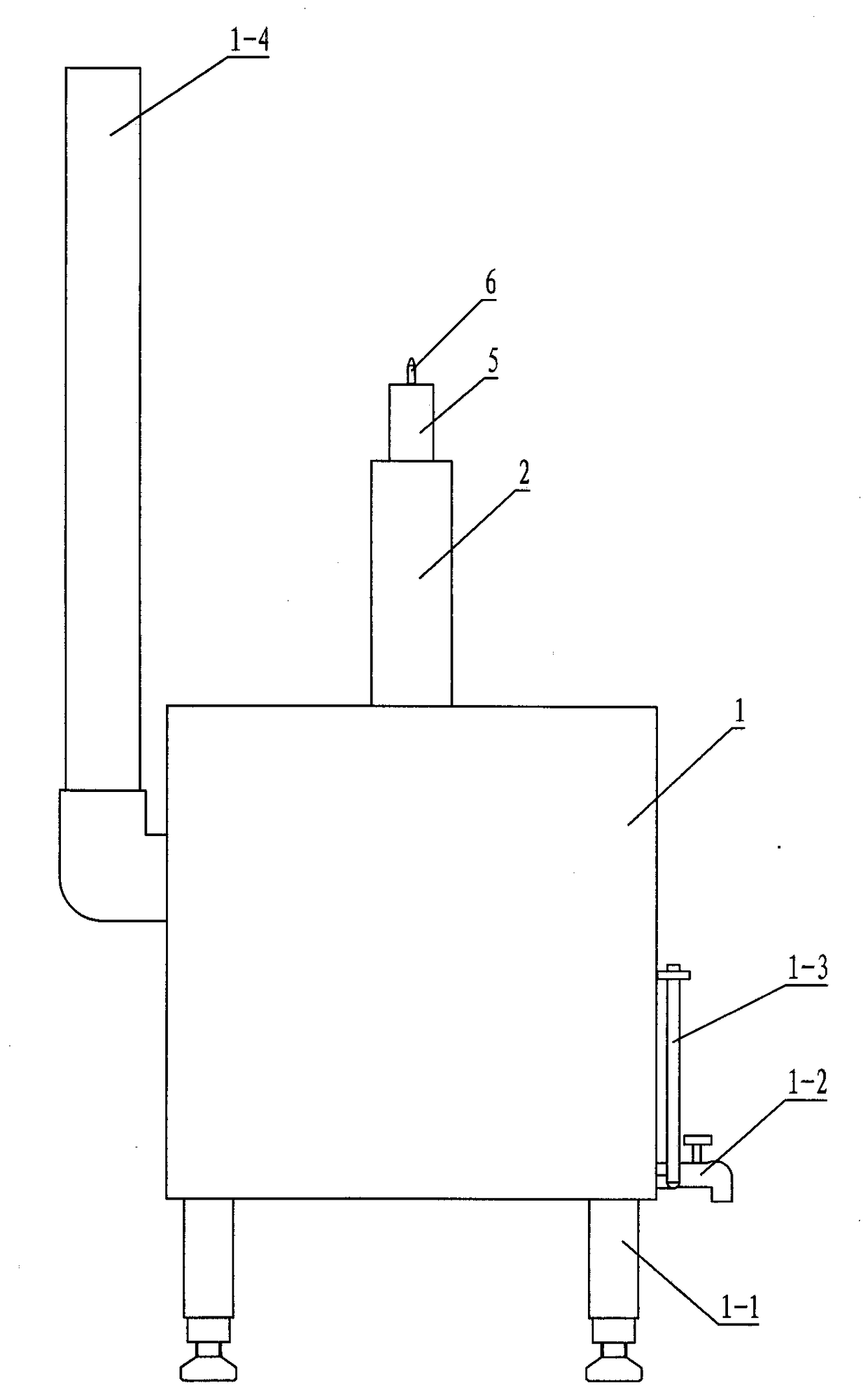

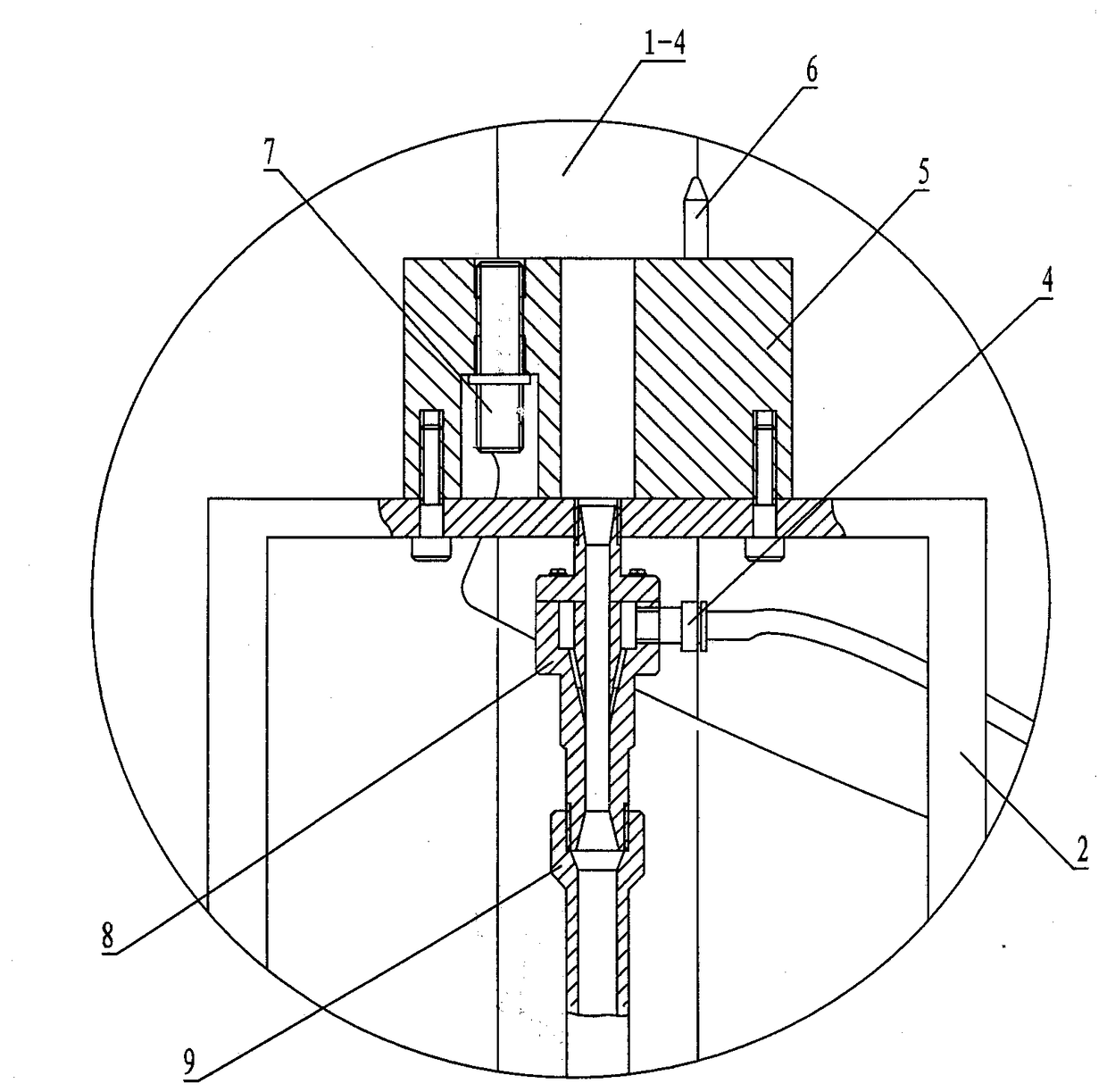

[0020] The turbocharger core oil pumping device includes a fuel tank 1, a bracket 2, a solenoid valve 3, an intake pipe joint 4, a connecting seat 5, a positioning pin 6, a proximity switch 7, an oil extractor 8 and an oil outlet pipe 9.

[0021] The front wall of the fuel tank 1 is respectively provided with an oil discharge tap 1-2, an oil mark 1-3, and an exhaust pipe 1-4 is arranged on the rear wall, and the exhaust pipe 1-4 communicates with the inner cavity of the fuel tank 1. The bottom of 1 is provided with adjustable foot support 1-1.

[0022] The connecting seat 5 is respectively provided with an oil outlet hole 5-1, a step hole 5-2 for installing the proximity switch 7, a threaded hole 5-5 for installing the positioning pin 6 and a threaded hole 5-4 connected with the bracket 2 , The small hole end of the step hole 5-2 is provided with an internal thread 5-3.

[0023] The oil extractor 8 includes a lower end body 8-2 and an upper end cover 8-1, the lower end body 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com