Clasping tool adjusting system and method based on adjustable clasping tool

An adjustment system and an adjustable technology, applied in the field of the holder adjustment system, can solve the problems of not being able to remember the size completely, inconvenient adjustment of the holder, and large workpieces, etc., so as to achieve fast internal processing, save production costs, and reduce burdens. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

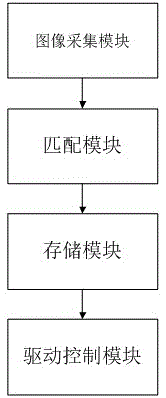

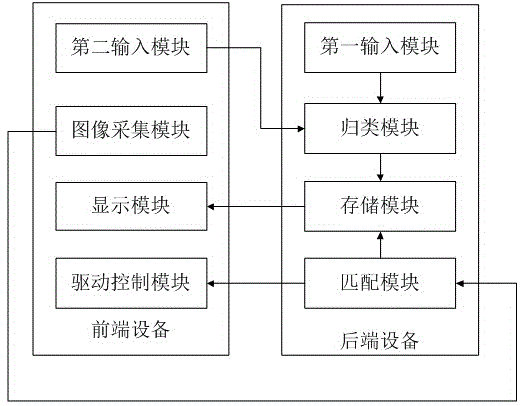

Method used

Image

Examples

example

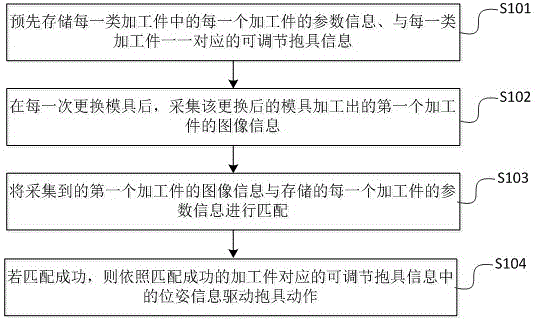

[0053] Assuming that the injection molding equipment has currently processed a batch of processed parts, and needs to process the next batch of similar processed parts (such as processed parts with similar shapes, processed parts with the same relationship and different sizes) in the future, then the next batch of similar processed parts The mold needs to be replaced before the workpiece is processed. After the mold is replaced, when the injection molding equipment processes the first workpiece through the replaced mold, the staff can press the acquisition button of the image acquisition device, or the image acquisition module automatically It is recognized that the processed piece is the first processed piece after the mold is replaced, and then the image acquisition module collects the image of the first processed piece.

[0054] The matching module is configured to match the collected image information of the first workpiece with the parameter information of each workpiece i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com