Patterned product and printing method for preparing the same

A pattern and product technology, which is applied in the design and printing of anti-counterfeiting products, can solve the problems of insufficient color gamut space and poor anti-counterfeiting performance, and achieve the effect of solving insufficient color gamut space and improving distinguishability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The printing method for preparing the patterned product provided by any of the above-mentioned technical solutions of the present invention provided in the embodiment of the present invention includes the steps of:

[0050] Sa, design at least two gravure layouts;

[0051] Sb, using at least two gravure plates to print patterns on the front and / or back of the substrate by nesting and / or overprinting.

[0052] At least two gravure layouts are printed by nesting and / or overprinting, and the color gamut of the pattern is larger, and the pattern on the patterned product has a full-color visual effect, engraved gravure embossed paper protrusions and ink accumulation synthesis The formed gravure hand feeling effect thus improves the distinguishability and anti-counterfeit property of patterned products (especially banknote products) from ordinary printed products.

[0053] As an optional implementation manner, step Sb is specifically:

[0054] At least two gravure plates ar...

Embodiment 1

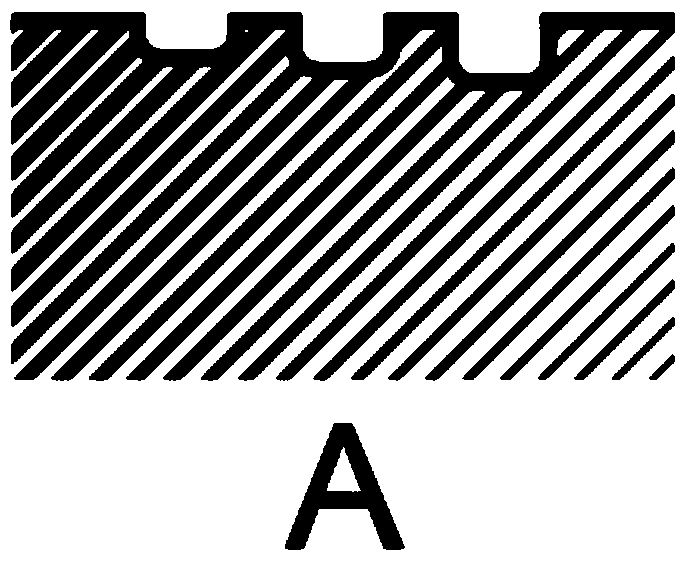

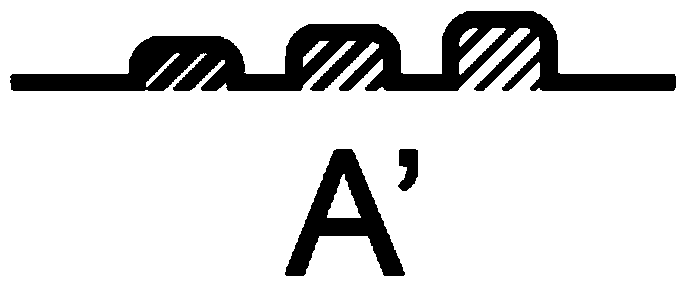

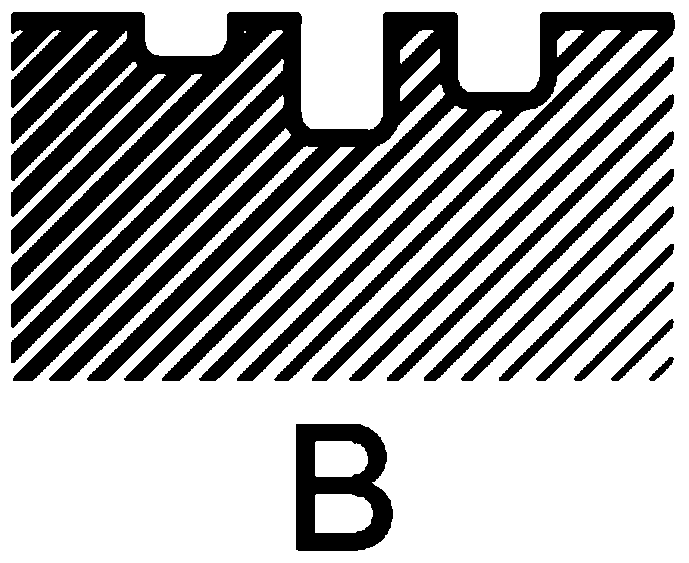

[0057] Such as figure 1 - Figure 8 As shown, three gravure printing plates (or called: gravure printing plate division, referred to as: gravure printing plate) A, B, C, each gravure printing plate is composed of patterns of different depths, of which the plate (face) A The pattern depth of version B is between 4 microns and 40 microns, and the depth of version B is between 8 microns and 48 microns. The pattern of version A and version B is mainly composed of fine points, lines, color blocks, continuous tone patterns, Continuous tone patterns or continuous tone and discontinuous tone mixed patterns, the depth of plate C is between 40 microns and 90 microns, mainly composed of engraved gravure dots and lines, and the patterns of each gravure plate are designed to be closely spaced. The matching relationship, the gray scale effect after printing is obvious, and the deep pattern has the feel of banknote gravure printing.

Embodiment 2

[0059] Such as Figure 9 - Figure 12 As shown, the multi-version overprint gravure process concept sample comprehensively demonstrates the new banknote design and printing method composed of multi-version gravure printing in terms of color and pattern composition. The sample sheet is composed of three gravure printing plates B1, B2, and B3. The plate grain depth of plate B1 and plate B2 is between 4 microns and 40 microns. The patterns are mainly composed of fine points, lines, color blocks, continuous tone patterns, Discontinuous tone patterns or continuous tone and discontinuous tone mixed patterns, among which the plate B3 has a depth of 40 microns to 100 microns, mainly composed of dots and lines of traditional engraved gravure printing, and the patterns of each plate are closely designed. The matching relationship; each block is printed with three tones, B1 version is printed with B1-1, B1-2, B1-3, B2 version is printed with B2-1, B2-2, B2-3, and B3 version is used B3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com