Spiral injection type material injection molding machine

An injection type, injection molding machine technology, applied in the field of screw injection material injection molding machines, can solve the problems of unreachable, increased manufacturing cost, complex injection molding machine structure, etc., and achieves the effects of convenient use, reliable performance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

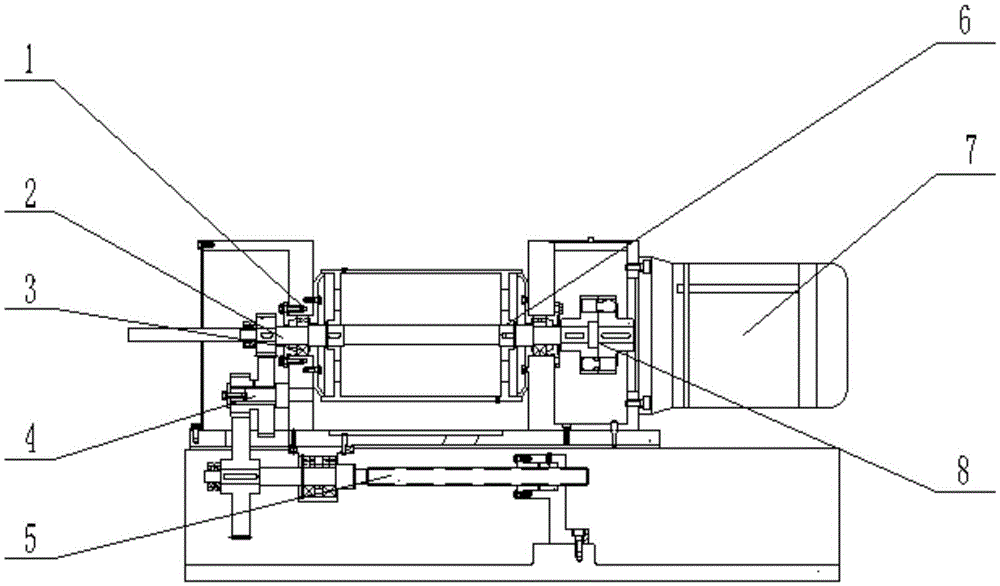

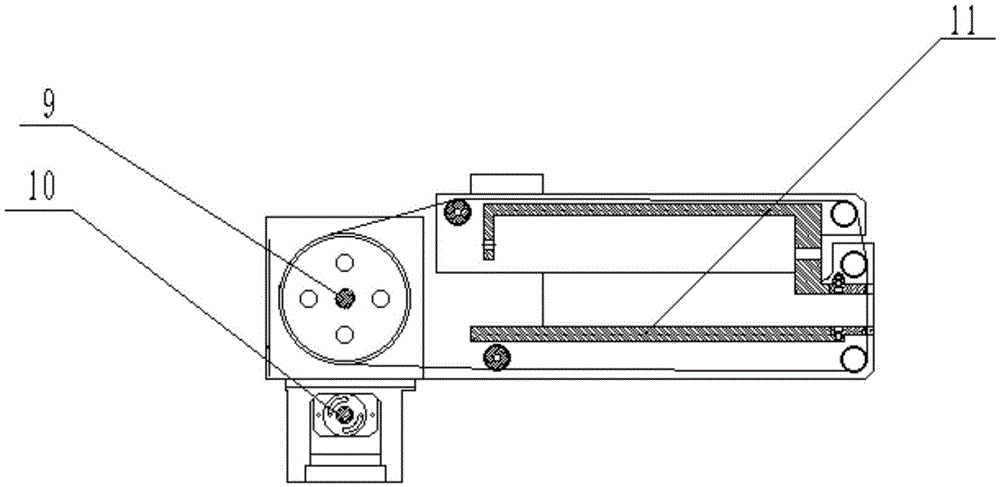

[0014] Such as figure 1 , figure 2 As shown, a screw injection type material injection molding machine includes a mold clamping mechanism (1), a premolding plunger injection screw (2), and a displacement sensor (4). The end of the mold clamping mechanism (1) is provided with a premolding The plunger injection screw (2); the pre-plastic plunger injection screw (2) cooperates with the displacement sensor (4) through the automatic oil shortage alarm device (3); the displacement sensor (4) is installed in the double cylinder balance The lower end of the injection system (5); the dual-cylinder balanced injection system (5) is connected to the power transmission device (6) through the automatic oil shortage alarm device (3); the power transmission device (6) and the feeding device (7 ) is fixed by small bolts (3); the feeding device (7) is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com