Polymer composition for improved grade plastics from recycled material

A composition and polymer technology, applied in the field of polymer compositions, can solve the problems of low impact strength, poor consistency, unstable mechanical properties, etc., and achieve the effects of increasing MFR, reducing demand, and increasing impact strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

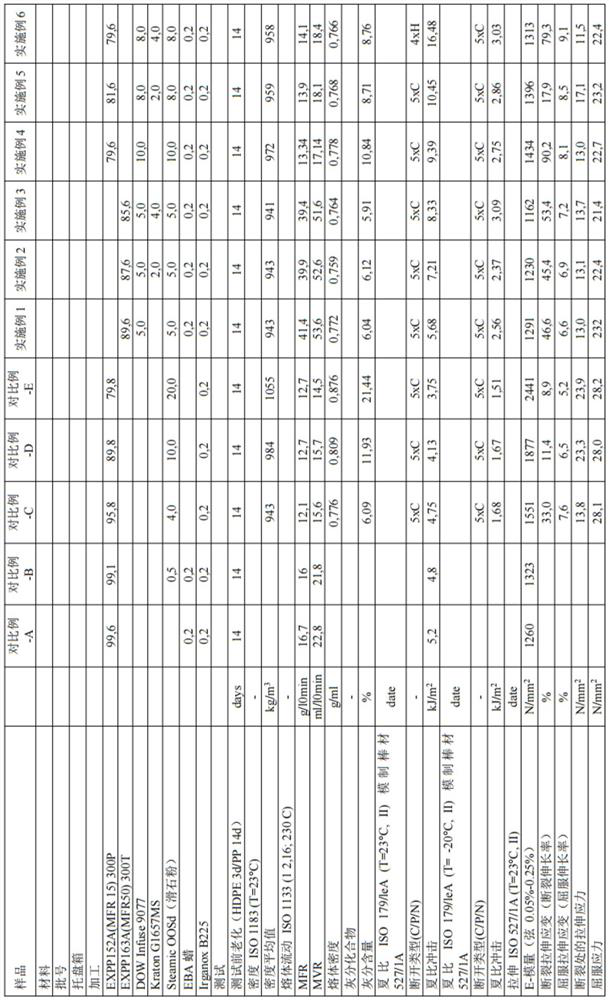

Examples

Embodiment approach

[0108] In a preferred embodiment, the polymer composition comprises 75-90 wt% recycled polypropylene, 0.1-1.9 wt% styrene ethylene butylene styrene block copolymer, 1-20 wt% polyolefin elastomer and 2-20 wt% talc.

[0109] In another embodiment, the polymer composition comprises 80-86 wt% recycled polypropylene, 0.5-1.5 wt% styrene ethylene butylene styrene block copolymer, 2-15 wt% polyolefin elastomer and 3 - 10 wt% talc.

[0110] In another embodiment, the polymer composition is preferably used for injection molding of articles.

[0111] The polymer composition according to the present invention may further comprise optional components other than the aforementioned components of the polymer composition, such as additives, wherein the sum of the aforementioned components and optional components is 100% by weight of the total polymer composition .

[0112] Accordingly, the present invention relates to polymer compositions consisting of the aforementioned components and opt...

Embodiment

[0118] Quality Testing and Standards

[0119] For quality testing, samples are taken during processing and from the final product. Melt mass flow rate (MFR) was measured on days 3 and 10 of aging. MFR and melt volume flow rate (MVR) were evaluated using ISO 1133-1:2011, 2.16 kg, T=230°C. For POE, MFR and MVR are evaluated using ISO 1133-1:2011 at 190°C and 2.16kg.

[0120] Cold xylene solubles (CXS) are measured using ISO 16152:2005, T = 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com