A metal mesh explosion-proof vacuum insulation glass and its preparation method

A technology of vacuum insulation and metal mesh, applied in the direction of metal layered products, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of large glass thickness, unsatisfactory thermal insulation performance, serious consumables, etc., to achieve guarantee Transparency, enhanced heat insulation effect, enhanced safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

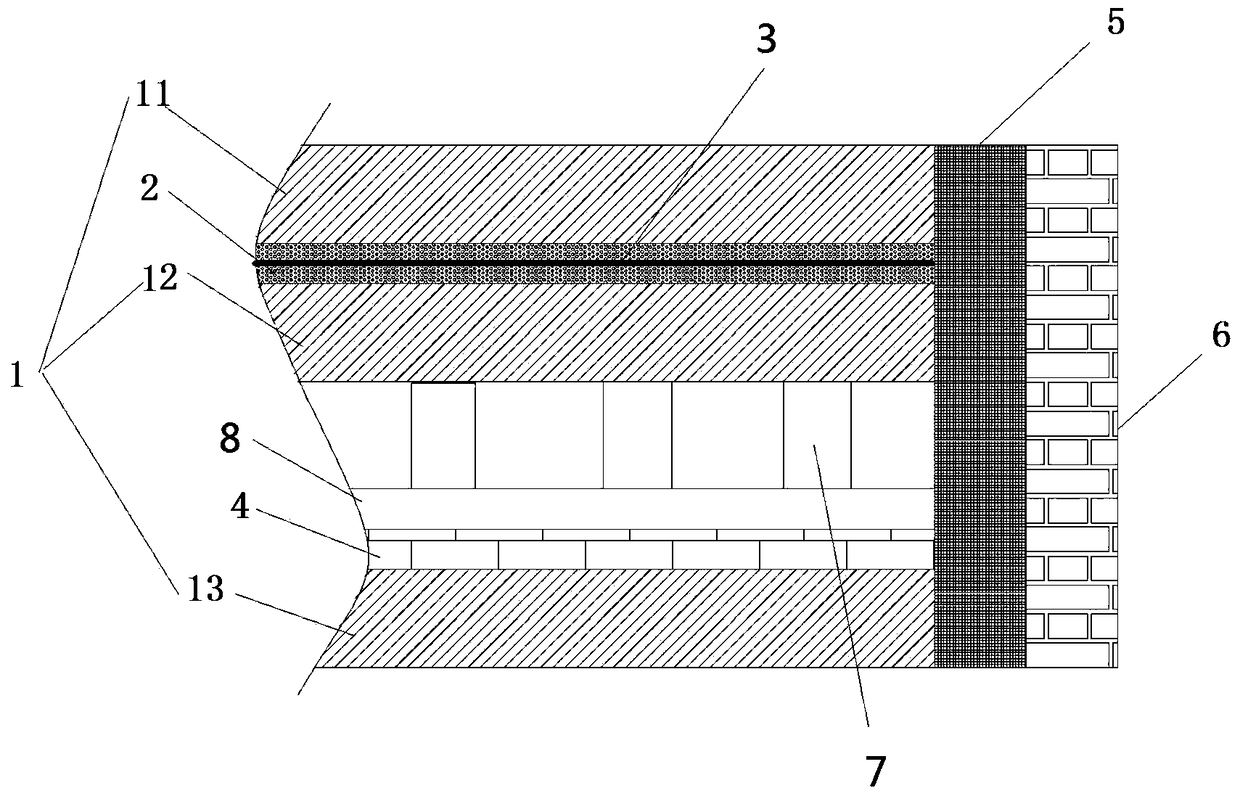

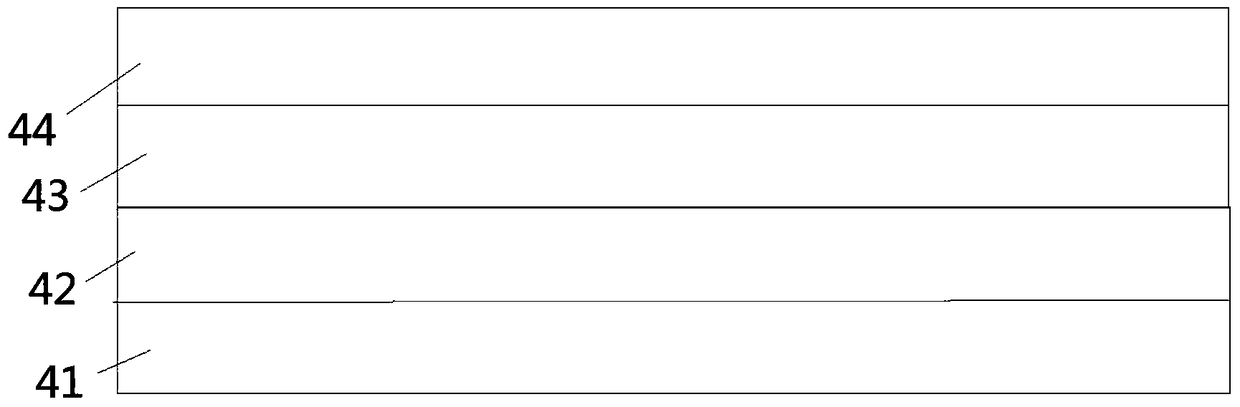

[0018] refer to Figure 1~Figure 2 , a metal mesh explosion-proof vacuum insulation glass and its preparation method provided by the present invention, comprising: a glass layer 1, including: a first glass layer 11, a second glass layer 12, and a third glass layer stacked from top to bottom 13; interlayer 2, arranged between the first glass layer 11 and the second glass layer 12; metal mesh 3, embedded in the interlayer 2; infrared reflection layer 4, arranged on the upper surface of the third glass layer 13 The stress protection layer 8 is arranged on the upper surface of the infrared reflection layer 4; the sealing layer 5 is coated around the glass layer 1 along the direction perpendicular to the glass layer 1; the protective layer 6 is longitudinally coated on the outer side of the sealing layer 5 ; A set of supports 7 is dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com