Method for preparing housing unit by integral molding from inside to outside and the housing unit produced

A house and integrated technology, which is applied in the field of preparation of integral molding of housing units, can solve the problems of many connection nodes, high construction costs, high material consumption, etc., and achieve the effect of meeting functional requirements, rich modeling texture, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

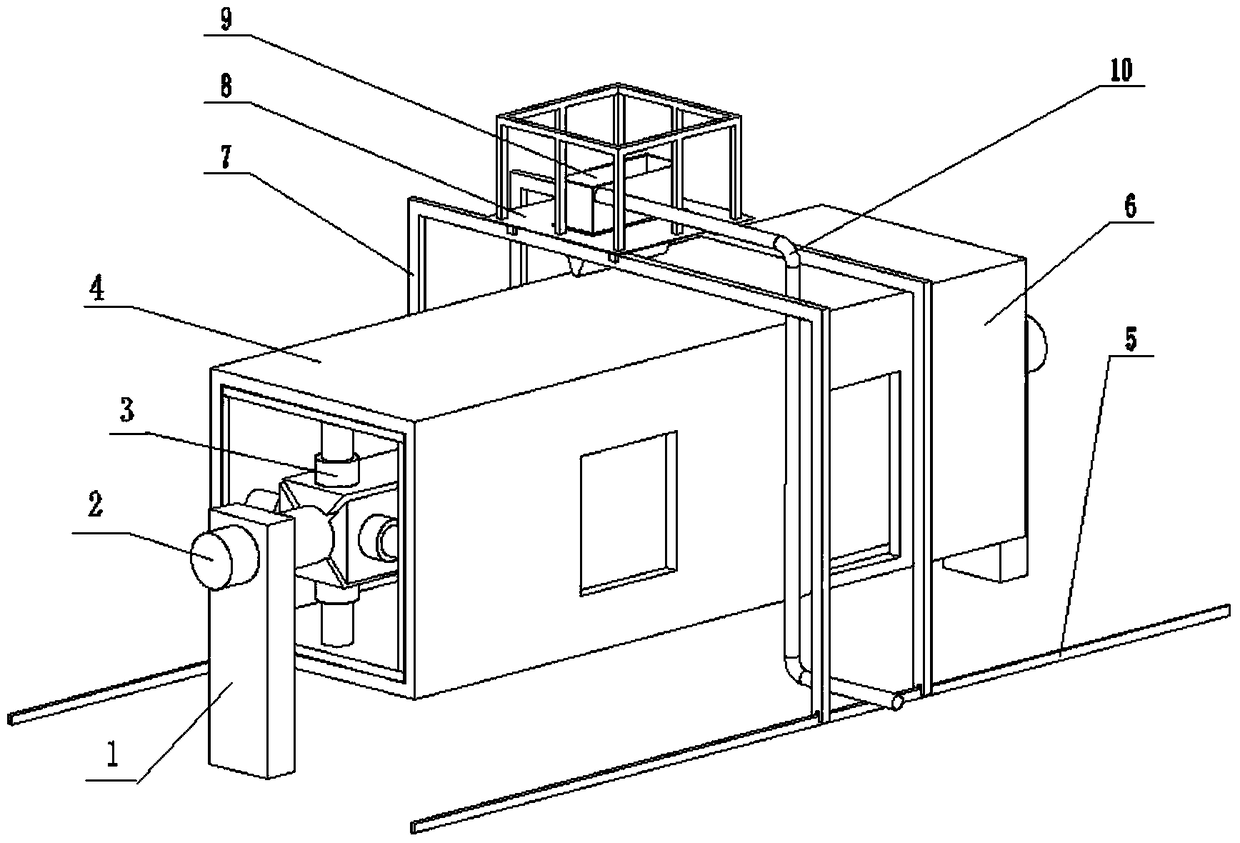

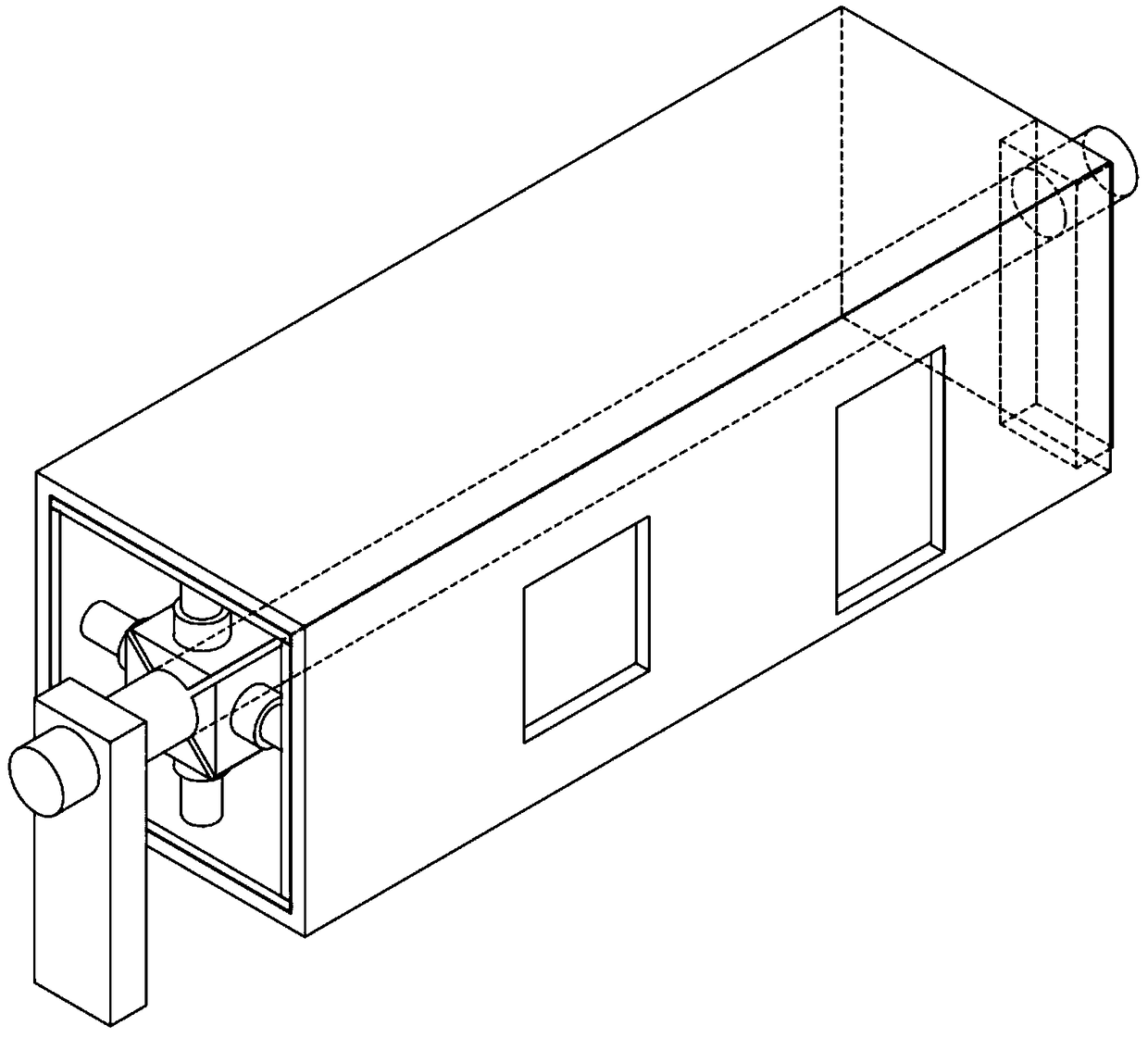

[0031] Preparation of one-time molding preparation of housing units

[0032] Step 1, preparing a frame mold driven by a driving device that can rotate longitudinally and / or laterally along the mold and whose longitudinal and / or lateral size can be adjusted;

[0033] Step 2, preparing the barrel dragon skeleton;

[0034] Step 3, prepare the inner wall layer mortar:

[0035] Using water, white cement, quartz sand or river sand, waterproof curing agent, reinforcing agent, flexibilizer and / or surface coloring agent as raw materials, prepare inner wall layer mortar by known method;

[0036] Step 4, prepare middle layer mortar; Prepare with following raw material according to known method:

[0037] Water, ordinary Portland cement or rapid hardening aluminum sulfate cement as binder, quartz sand or river sand as aggregate, alkali-resistant fiber yarn, alkali-resistant fiber felt and / or nylon crack-resistant fiber as fiber material, Waterproof curing agent, strengthening agent, sof...

Embodiment 2

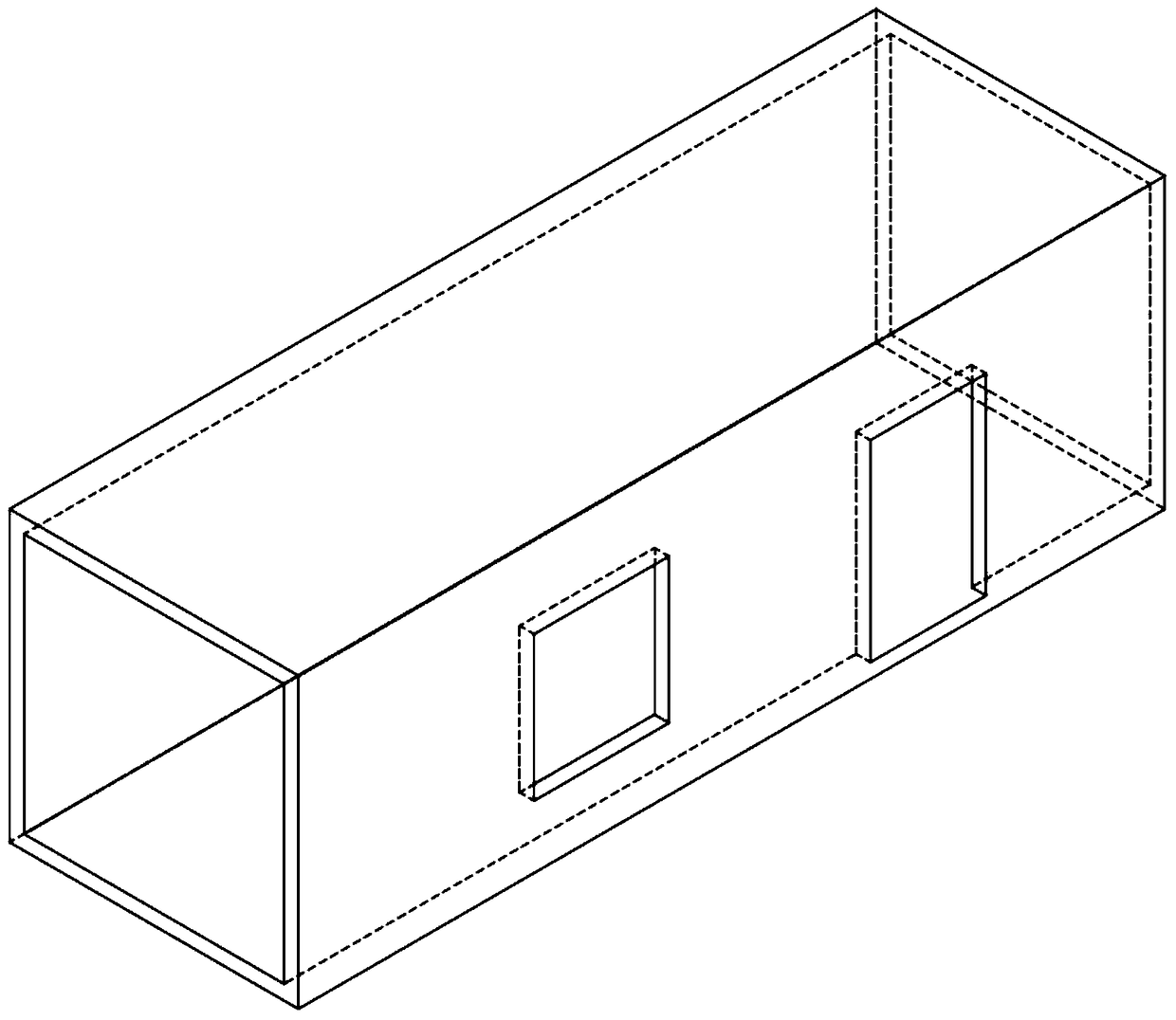

[0049] One-time molding to prepare housing units with rough surface effects on the outer surface, such as image 3 as shown,

[0050] Other methods are the same as in Example 1 except for the spray printing with integrated interior and exterior decoration and the preparation of mortar with a rough surface effect.

Embodiment 3

[0052] Integral molding to prepare housing units with window frames

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com