Prefabricated structure decoration integral inner partition plate and preparation method thereof

A technology of prefabricated structures and internal partitions, applied to walls, building components, manufacturing tools, etc., can solve problems such as non-environmental protection, long construction period, harmful paint to human body, etc., achieve energy saving and environmental protection costs, shorten decoration time, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a prefabricated structure-decorated integrated interior partition wall panel, the method comprising the following steps:

[0023] S1: Select a special texture design scheme and use 3D printing technology to make a texture sample for molding;

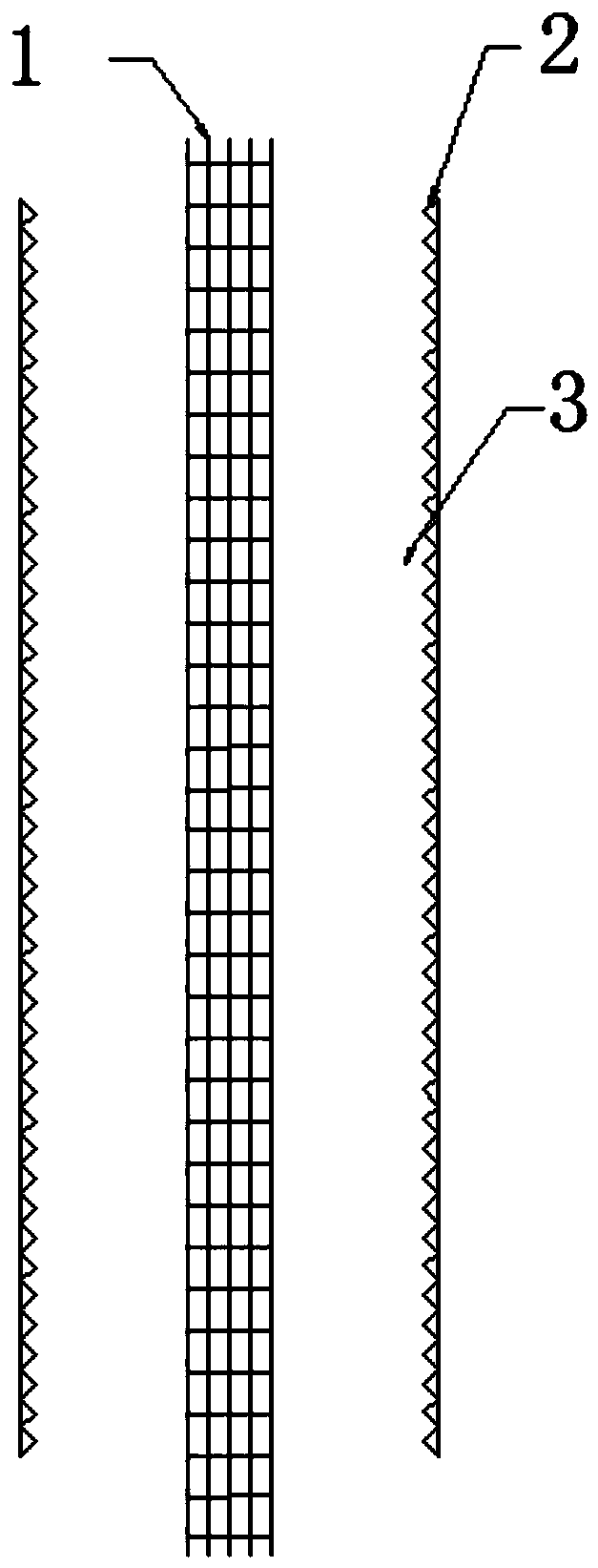

[0024] S2: Mix the curing agent into the silica gel, stir evenly, pour it into the sample for turning over the mold, level it, remove the mold, and prepare the decorative surface mold 2;

[0025] S3: The following components of lightweight concrete slurry: 300 parts of cement, 50 parts of fly ash, 100 parts of slag, 50 parts of sludge ceramsite, 9 parts of admixture, 0.3 parts of thickener, 2 parts of foaming agent, water 160 parts; Add cement, fly ash, slag, sludge ceramsite, and 75% water to the mixer in sequence, stir for 1 minute, and then add the remaining 25% water, additives, thickeners, and foaming agents Mixer, stir for 1 minute to make lightweight concrete slurry;

[0026] S4: Clean up the vertic...

Embodiment 2

[0030] A method for preparing a prefabricated structure-decorated integrated interior partition wall panel, the method comprising the following steps:

[0031] S1: Select a special texture design scheme and use 3D printing technology to make a texture sample for molding;

[0032] S2: Mix the curing agent into the silica gel, stir evenly, pour it into the sample for turning over the mold, level it, remove the mold, and prepare the decorative surface mold 2;

[0033] S3: The following components of lightweight concrete slurry: 375 parts of cement, 85 parts of fly ash, 225 parts of slag, 115 parts of sludge ceramsite, 11 parts of admixture, 04 parts of thickener, 3.5 parts of foaming agent, water 180 parts; Add cement, fly ash, slag, sludge ceramsite, and 75% water to the mixer in sequence, stir for 2 minutes, and then add the remaining 25% water, admixtures, thickeners, and foaming agents Mixer, stirring for 2 minutes to make lightweight concrete slurry;

[0034] S4: Clean up ...

Embodiment 3

[0038] A method for preparing a prefabricated structure-decorated integrated interior partition wall panel, the method comprising the following steps:

[0039] S1: Select a special texture design scheme and use 3D printing technology to make a texture sample for molding;

[0040] S2: Mix the curing agent into the silica gel, stir evenly, pour it into the sample for turning over the mold, level it, remove the mold, and prepare the decorative surface mold 2;

[0041] S3: The following components of lightweight concrete slurry: 450 parts of cement, 120 parts of fly ash, 350 parts of slag, 180 parts of sludge ceramsite, 13 parts of admixture, 0.5 parts of thickener, 5 parts of foaming agent, water 200 parts; add cement, fly ash, slag, sludge ceramsite, and 75% water to the mixer in sequence, stir for 3 minutes, and then add the remaining 25% water, additives, thickeners, and foaming agents Mixer, stirring for 3 minutes to make lightweight concrete slurry;

[0042] S4: Clean up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com