A core plate online monitoring system and method of a diaphragm filter plate

A membrane filter plate and monitoring system technology, applied in the direction of measuring force, measuring heat, measuring device, etc., can solve the problems such as the service status and monitoring of the filter plate of the filter press that have not yet occurred, and achieve accurate and rapid elimination of filter plate failures and hidden safety hazards. , Guaranteed benefits, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

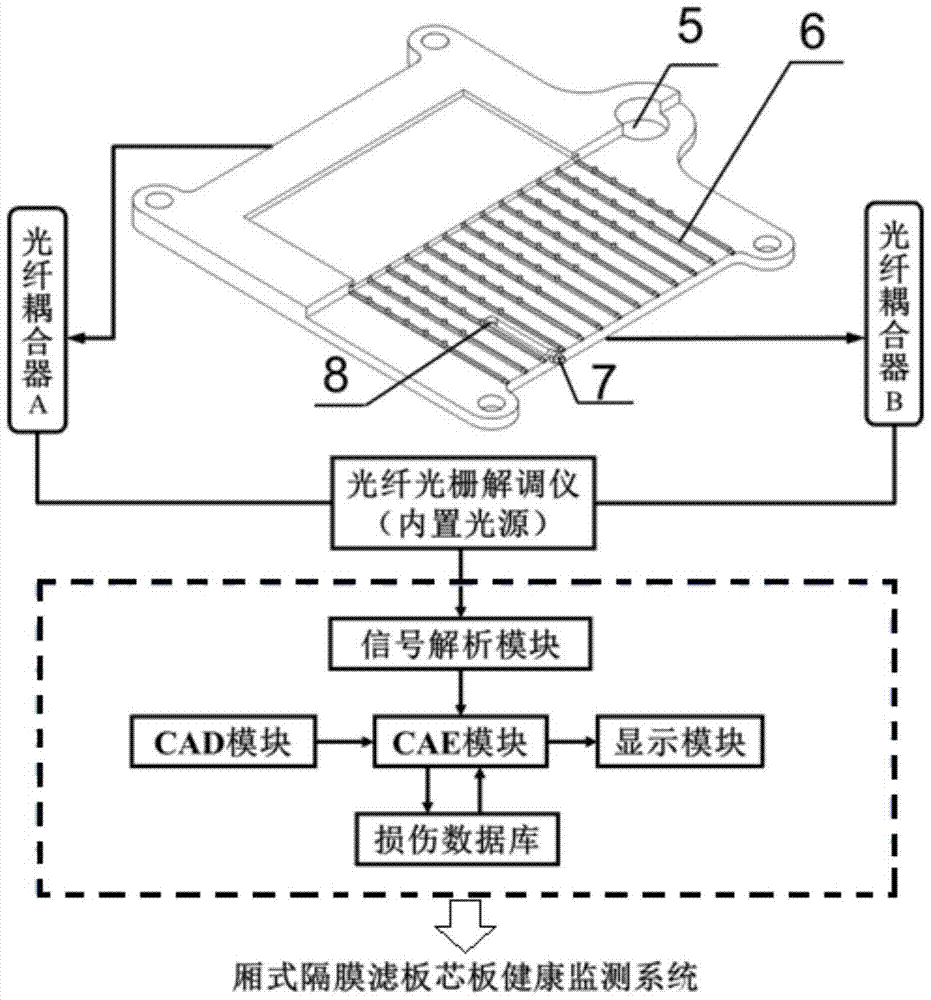

[0078] Embodiment 1: An on-line health monitoring device and method for a core plate of an upper-feed box-type diaphragm filter plate.

[0079] Such as image 3 As shown, the system includes: a thin rod-shaped bidirectional lead fiber Bragg grating pair sensor insert 6, a fiber coupler, a fiber grating digital demodulator, a computer system, and the like.

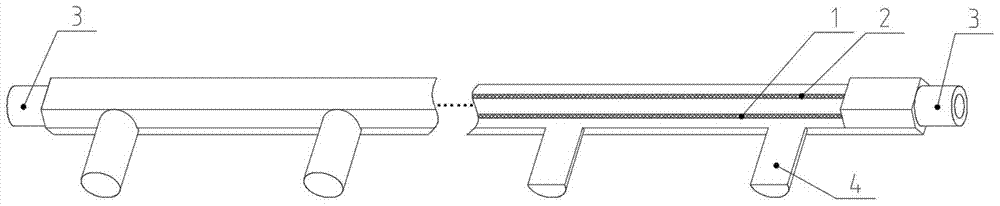

[0080] The structure of thin rod-shaped bidirectional lead fiber Bragg grating pair sensor insert 6 is as follows figure 1 As shown, there are leads at both ends of each fiber grating, forming two signal channels. After being broken by external force, one double-lead grating sensor can become two single-lead grating sensors, and the grating can work normally, ensuring online monitoring process monitoring stability.

[0081] (1) According to the size of the core plate of the upper-feed box-type diaphragm filter plate, 26 optical fibers with a cladding diameter of 40 μm are engraved to engrave gratings. Each optical fiber ...

Embodiment 2

[0088] Embodiment 2 An on-line health monitoring device and method for a core plate of a middle-feed box-type membrane filter plate

[0089] Such as Figure 4 As shown, the system includes: a thin rod-shaped unidirectional lead fiber Bragg grating sensor insert, a thin rod-shaped bidirectional lead fiber Bragg grating sensor insert, a fiber coupler, a fiber grating digital demodulator, a computer system, and the like.

[0090] The structure of the thin rod-shaped unidirectional lead fiber Bragg grating pair package insert 10 is as follows figure 2 As shown, each fiber grating has only one lead wire, and the fiber grating with one-way lead is convenient for arrangement around the feeding hole in the center of the core plate of the diaphragm filter plate.

[0091] (1) According to the shape, structure, and size of the core plate of the middle-feed box-type diaphragm filter plate, 22 optical fiber gratings with a cladding diameter of 40 μm of bidirectional leads were engraved. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com