Sealing rubber material aging simulation online monitoring method

A sealing rubber and rubber technology, which is applied in the analysis of materials, material impedance, measuring devices, etc., can solve the problems of incompatibility of sealing rubber materials, affecting the sealing performance of sealing rubber, complex use environment, etc., and achieve high accuracy of monitoring results, The effect of improving monitoring accuracy and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention discloses an on-line monitoring method for aging simulation of sealing rubber materials, which is used to predict the remaining service life of sealing rubber materials, including:

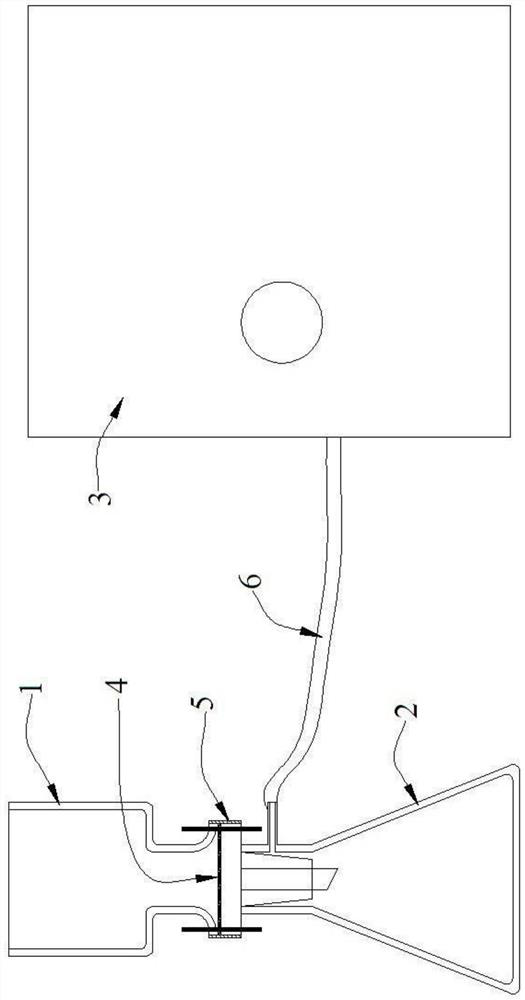

[0047] Step S1, when the sealing rubber material is put into use, use the same online monitoring sample as the sealing rubber material, clamp the online monitoring sample with a measuring probe and place it in the use environment where the sealing rubber material is located In order to make the on-line monitoring sample synchronously simulate the stress state and environmental state of the sealing rubber material during use, that is, the on-line monitoring sample and the sealing rubber material are aging synchronously;

[0048] Step S2, using an impedance measuring device to apply an alternating current to the on-line monitoring sample to measure the impedance Z of the on-line monitoring sample at the current moment; and, detecting the ambient temperature T of the use environme...

Embodiment approach

[0067] In the step S2, the impedance measuring device applies an alternating current to the online monitoring sample through the measuring probe and measures the impedance Z of the online monitoring sample 7 at the current moment;

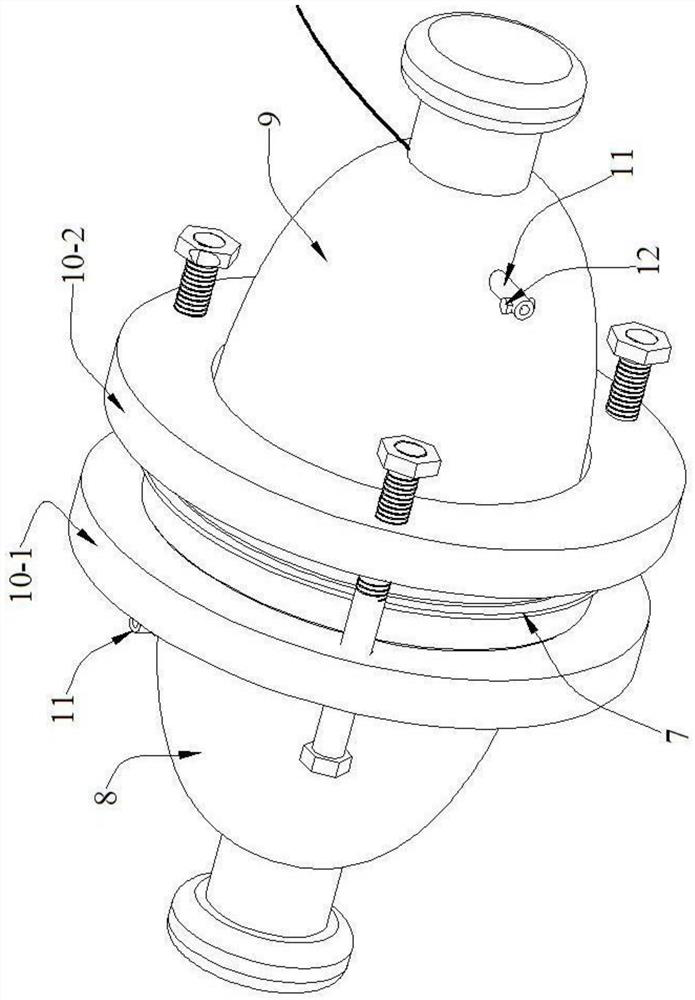

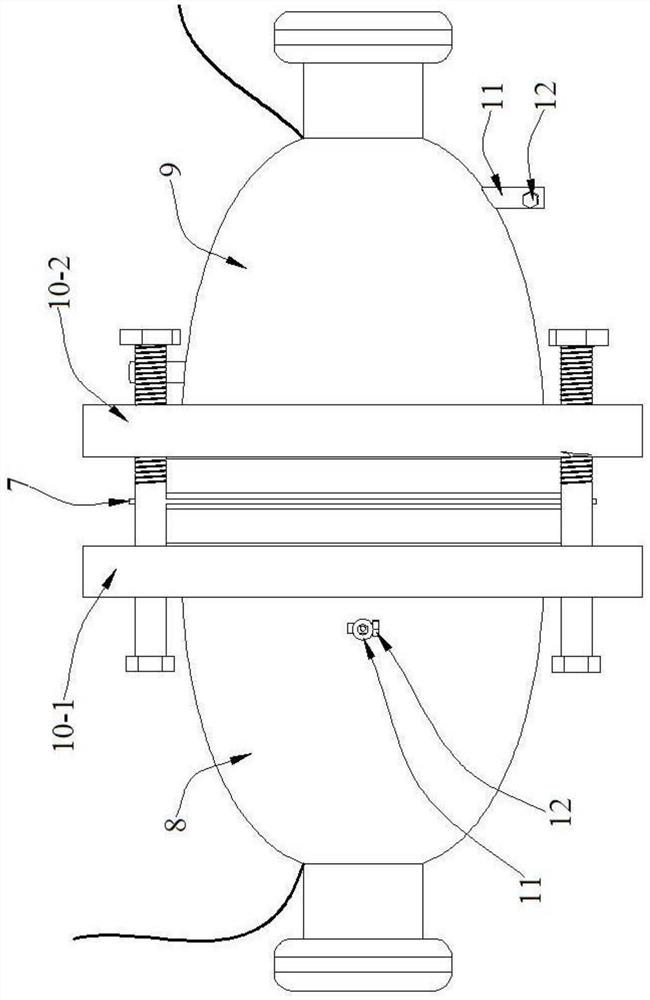

[0068] Such as Figure 2 to Figure 5 As shown, the measurement probe includes a first measurement electrode 8, a second measurement electrode 9 and a clamping mechanism, the online monitoring sample 7 is located between the first measurement electrode 8 and the second measurement electrode 9, and the clamp The tightening mechanism can clamp the first measuring electrode 8 and the second measuring electrode 9, and the first measuring electrode 8 and the second measuring electrode 9 are each electrically connected to the impedance measuring device through an electrode wire; wherein, The first measuring electrode 8 and the second measuring electrode 9 are preferably made of brass, silver-plated copper and other metals with strong corrosion resistance ...

Embodiment 3

[0074] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0075] Such as figure 2 and image 3 As shown, the first measuring electrode 8 and the second measuring electrode 9 are shell electrodes with concave cavities, and the online monitoring sample 7 is connected to the two concave cavities; the surface of the concave cavity is coated with Oil-resistant, acid-resistant, alkali-resistant paint, the outer walls of the first measuring electrode 8 and the second measuring electrode 9 are equipped with two connecting pipes 11 communicating with the cavity, and the connecting pipes 11 are equipped with valves 12; and , the cavity of the first measuring electrode 8 and the second measuring electrode 9 is filled with a contact medium through the valve 12, and the contact medium is the medium that the sealing rubber material comes into contact with during use, for example: oil, Acids, lyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com