solenoid actuated valve

An electromagnetic and valve seat technology, applied in the field of pressure regulating valves, can solve problems such as difficulty in regulating pressure and adverse effects on pressure regulation accuracy, and achieve the effect of improving regulating characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

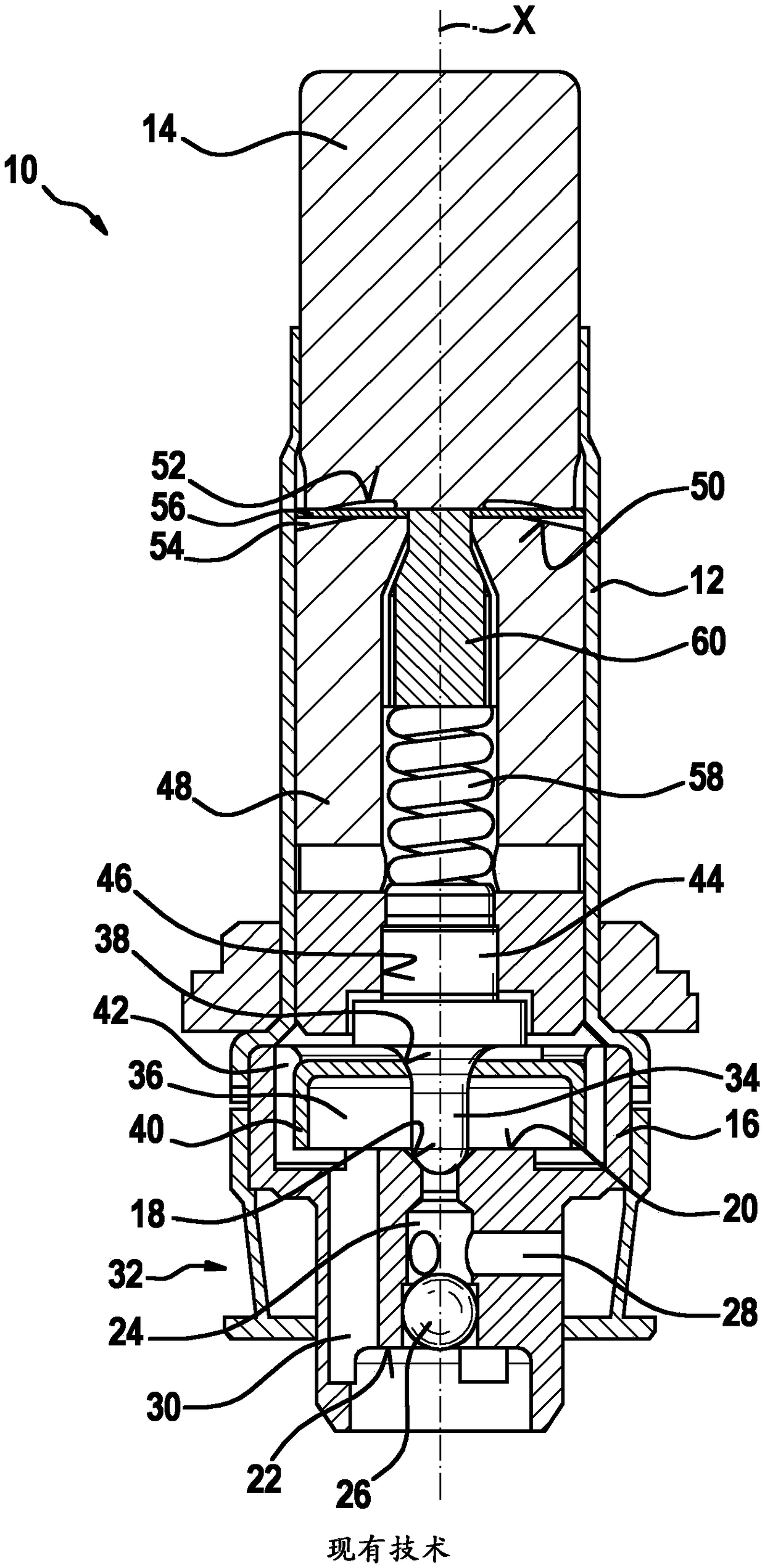

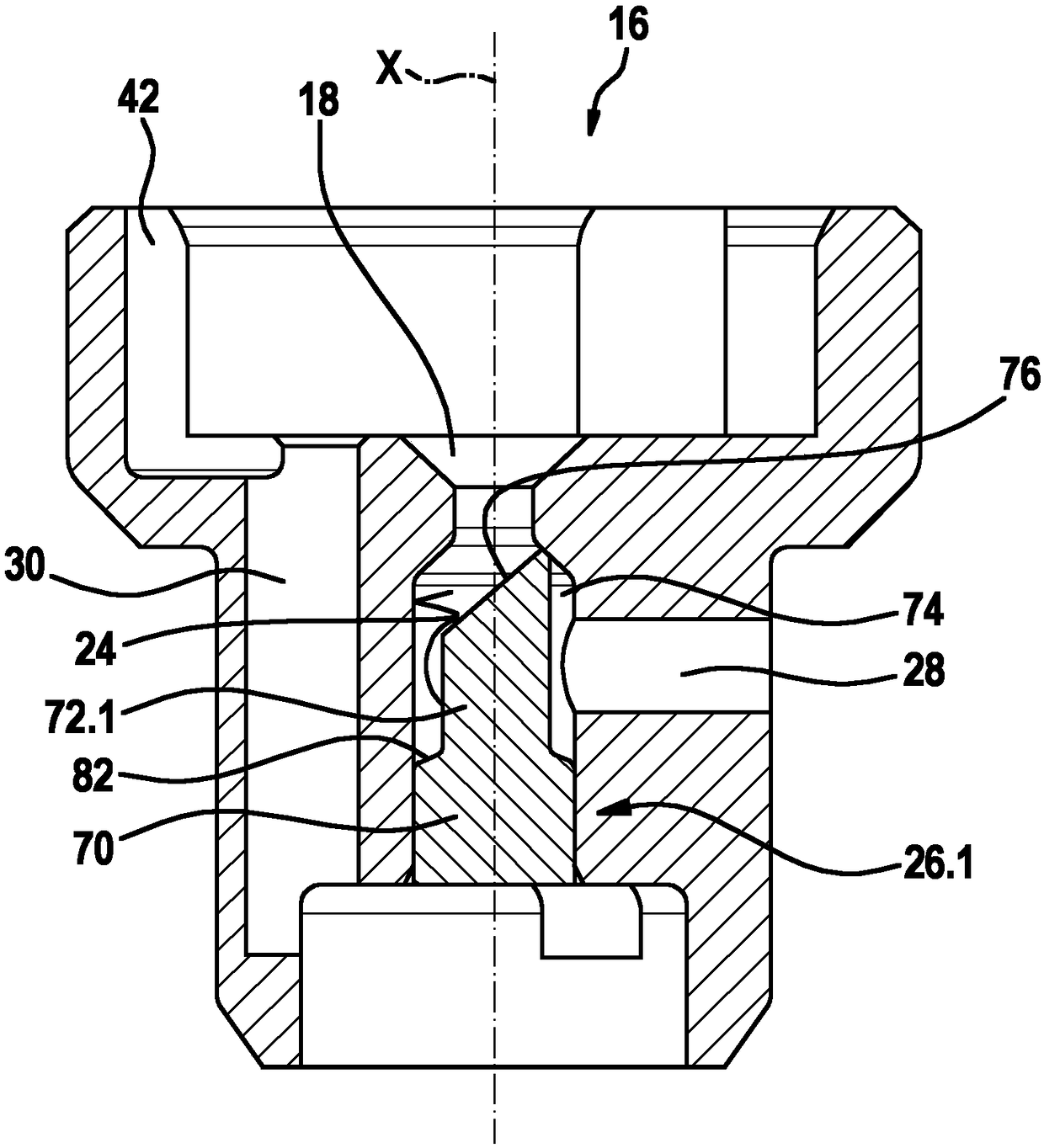

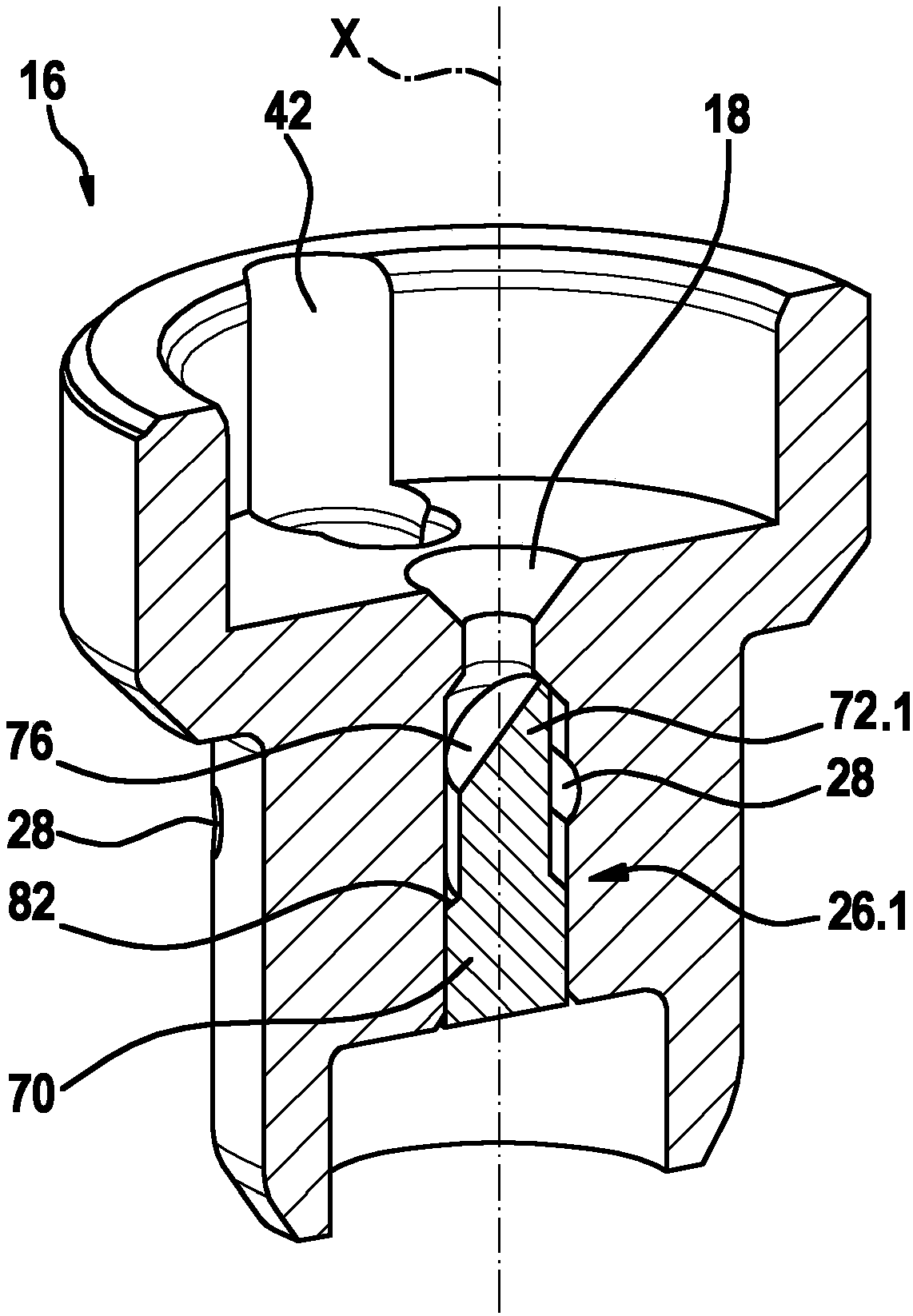

[0014] figure 1 A solenoid-actuated valve 10 known from the prior art is shown in longitudinal section. The illustration of the solenoid coil which completes the valve 10 has been intentionally omitted for the sake of clarity. The valve 10 has a sleeve-shaped valve housing 12, in the figure 1 A plug-shaped pole core 14 made of magnetically permeable material is inserted into the open end of the upper middle part. The pole core 14 is fixedly connected to the valve housing 12 . The valve housing 12 is in figure 1 The open end of the lower middle part is closed by a seat body 16 which is also fixedly connected to the valve housing 12 . The seat body 16 forms a valve seat 18 which is arranged on the longitudinal axis X-X of the valve 10 and is formed on the base of a first flat depression 20 which is open towards the interior of the valve housing 12 . The valve seat 18 itself is configured, for example, in the shape of a conical seat. Opposite the flat depression 20 which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com