Single-row or multi-row heating body containing at least two different sections

A heating body, single-row technology, applied in the field of manufacturing the above heating body, flat heating body or heating wall, to achieve the effect of uniform temperature distribution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

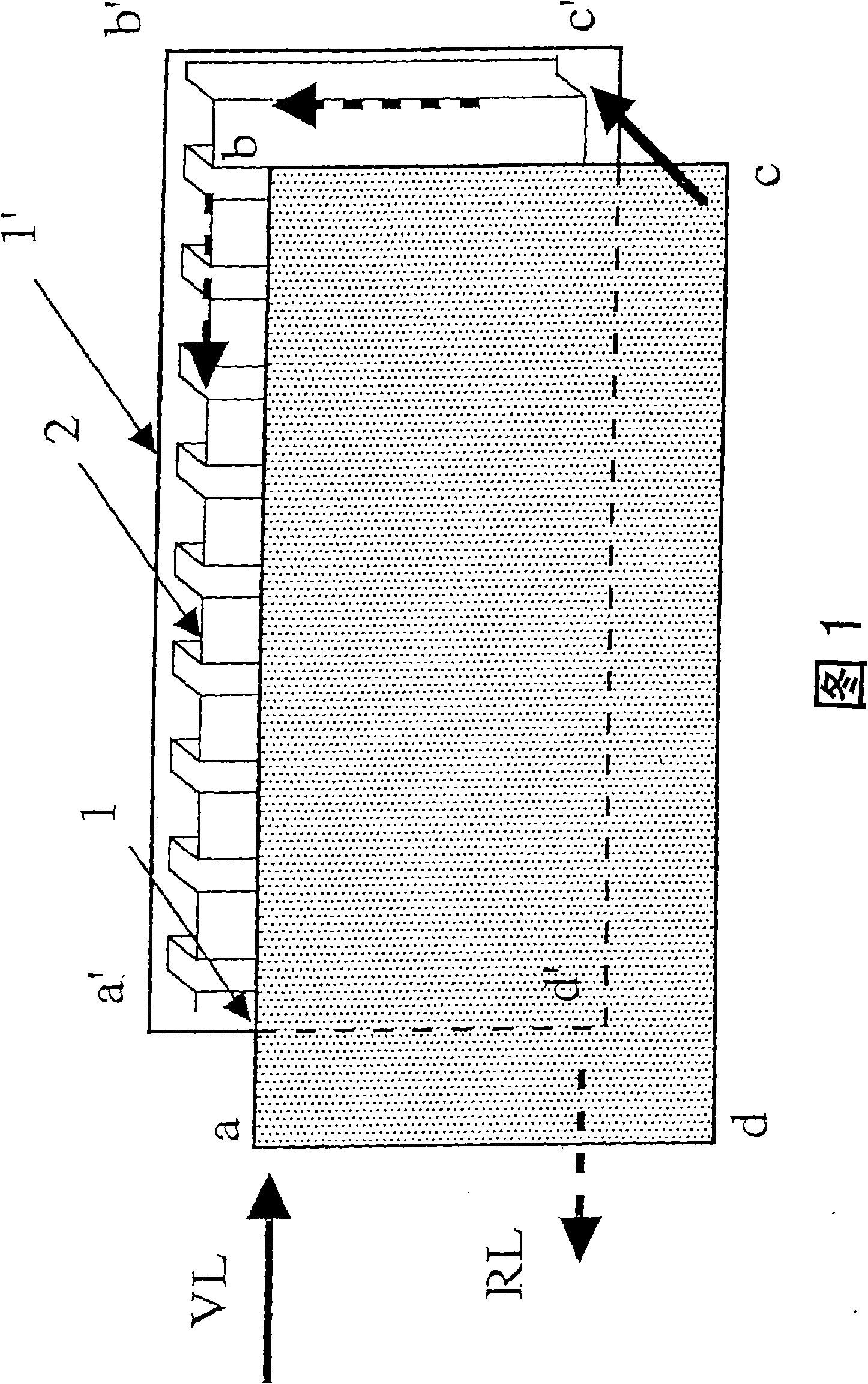

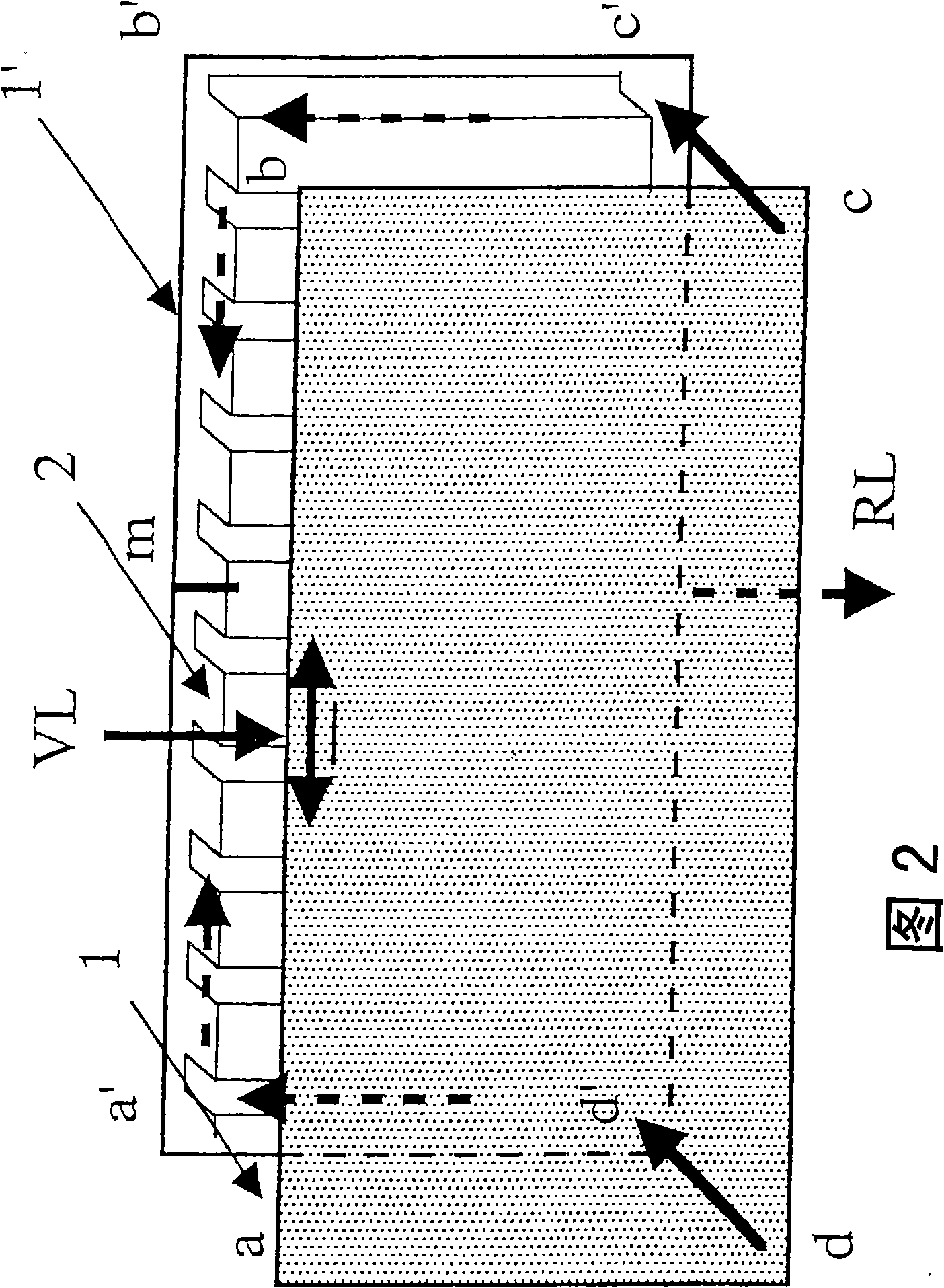

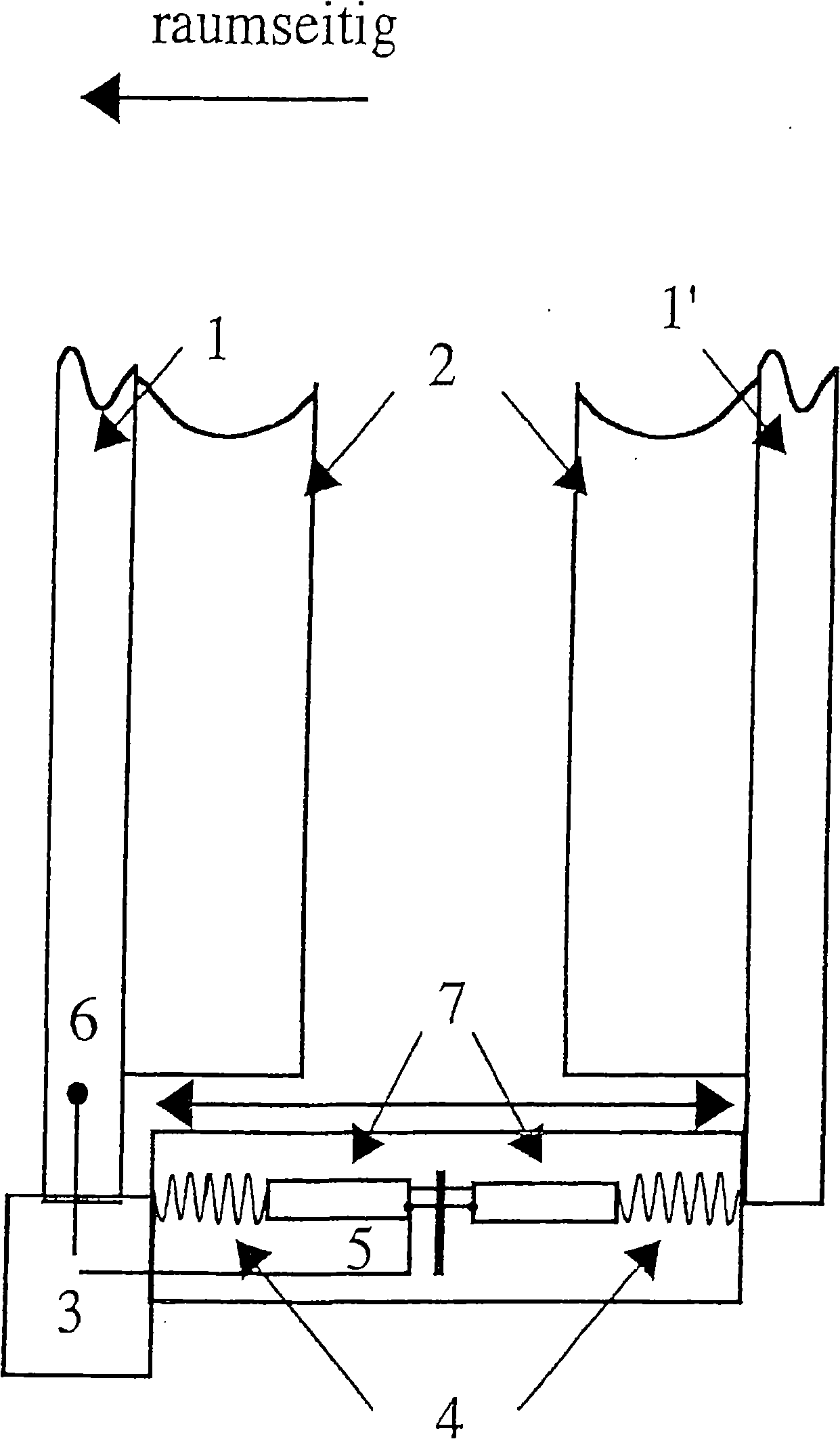

[0083] FIG. 1 shows a two-row heating element according to the invention with a so-called same-side connection at the top, wherein the inflow connection VL is located in the upper corner region a of the front heating plate 1 and the return connection RL is located in the rear heating plate 1. ' on the lower corner area d'. The hot water flowing in via the inflow connection is expediently distributed on the front heating plate before it is conducted via a connection section c-c', preferably a metal or plastic pipe, to the rear heating plate 1'. Expediently, the heating plate is formed from two half-shells or profiled plates, preferably made of sheet steel or plastic, which are welded or connected to one another in a watertight manner. In order to evenly distribute the flow medium, preferably water, the corresponding profile is designed such that a plurality of flow channels extending in the vertical direction a-d are provided in the heating plate and one each is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com