Pipe electromagnetism heating device and electromagnetism heating method

An electromagnetic heating device and pipeline technology, applied in the direction of induction heating device, pipeline heating/cooling, induction heating, etc., can solve the problems of reduced heating area, poor heating effect, and easy formation of laminar flow, etc., to increase heating power and equipment The effect of low cost and increased heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

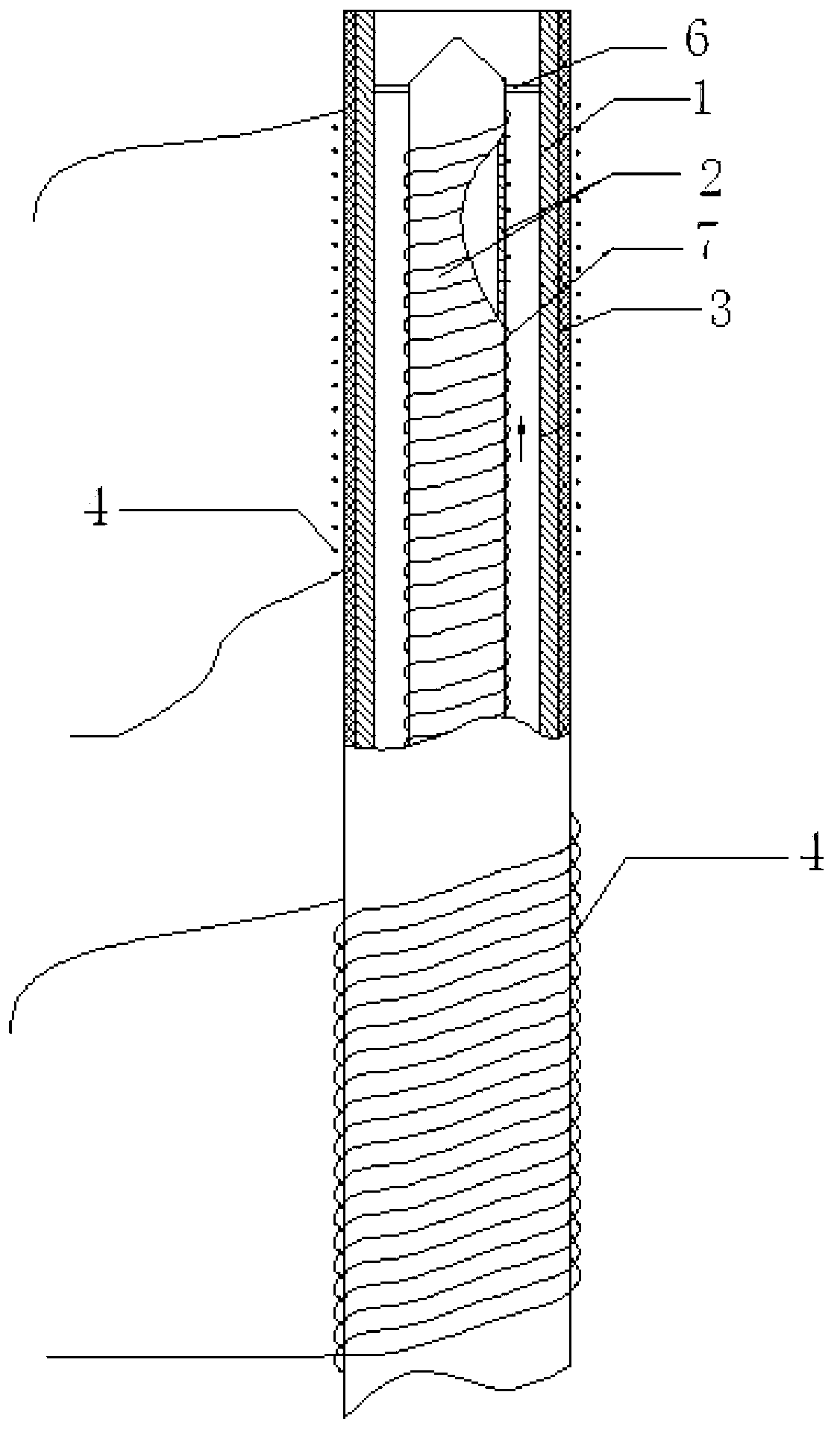

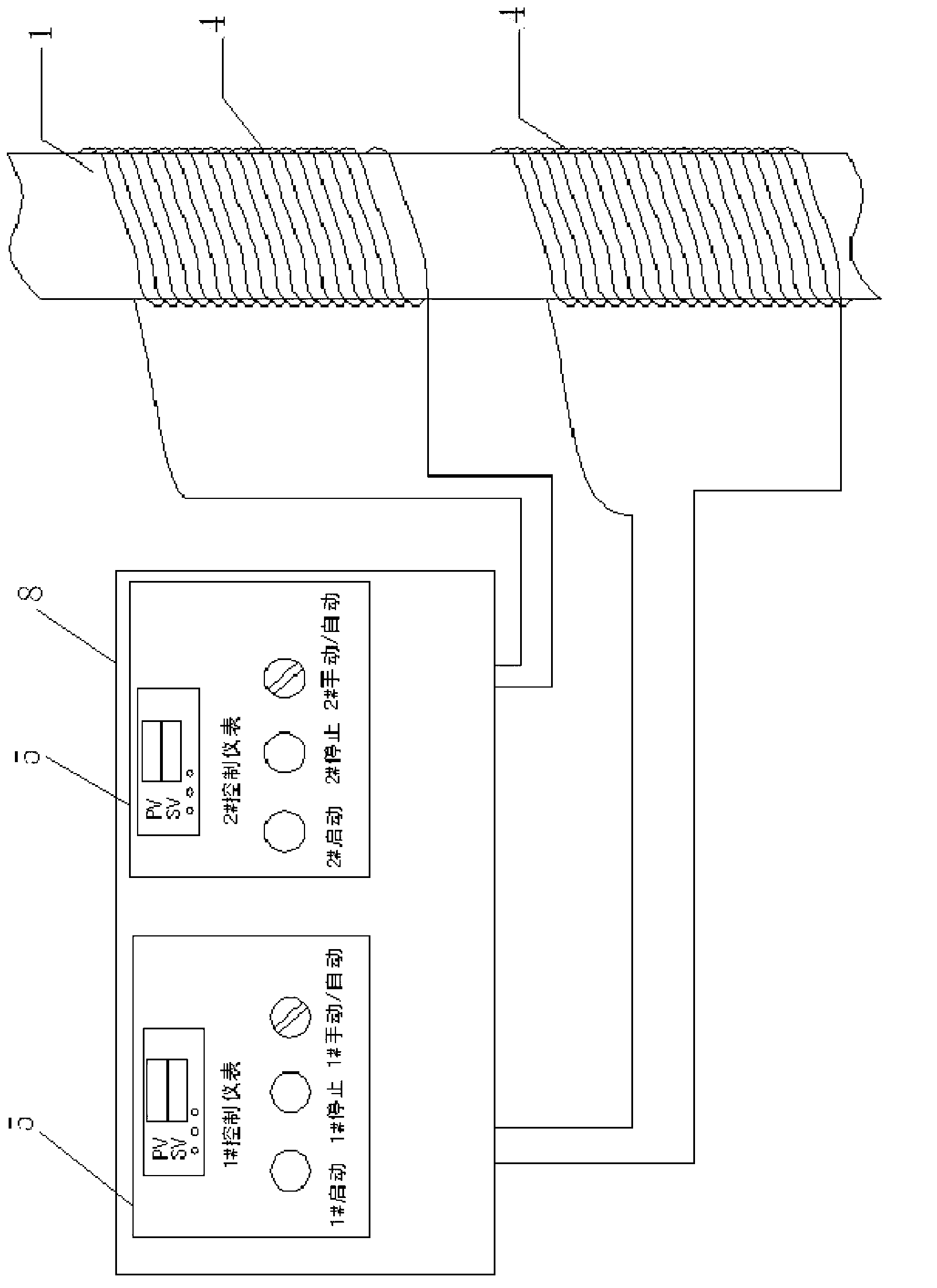

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The present invention is based on the following principles: pipeline electromagnetic heating is a heating technology that converts electric energy into heat energy by using the principle of electromagnetic induction to heat pipeline fluid. The pipeline must be made of magnetic material, and an electromagnetic induction coil is wound on the pipeline, and the frequency of the coil is 16-40KHz. The high-frequency current, the high-frequency changing current flowing through the coil will generate a high-frequency changing magnetic field. When the magnetic field lines in the magnetic field pass through the magnetically conductive metal material, an eddy current will be generated in the metal material, which will cause the metal material itself to heat itself at a high speed, and also That is, the pipeline itself generates heat to heat the liquid or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com