Electric heating element and pipeline electric heater

A technology of electric heating element and resistance wire, which is applied in the direction of pipeline heating/cooling, heating element shape, pipe/pipe joint/pipe fitting, etc., which can solve the problems of small effective density of electric heating element, complex structure of electric heating pipe, and large occupied space, etc. Achieve the effects of increasing effective density and heating power, compact structure, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

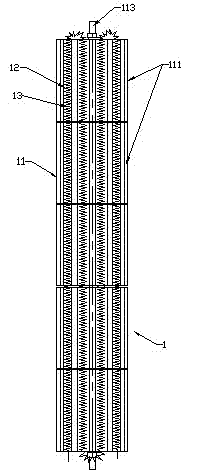

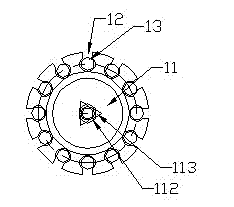

[0012] Such as figure 1 , figure 2 As shown, the electric heating element 1 includes a cylindrical base 11 made of refractory material, longitudinal installation grooves 12 are uniformly distributed on the outer cylindrical surface of the base, and a spiral resistance wire 13 is reciprocally placed in each installation groove 12 Inside, lead-out electrodes are set at both ends of the resistance wire. The base body 11 is composed of a multi-section cylindrical base body unit 111. A piercing hole 112 is provided in the center of the base body unit. A piercing bolt 113 passes through the piercing hole to connect each base body unit into a coaxial whole.

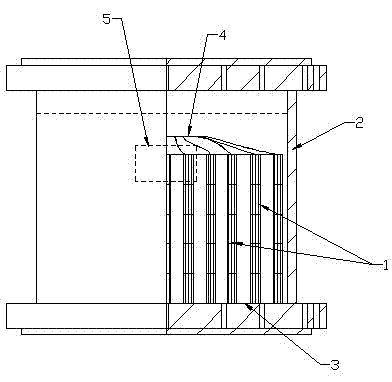

[0013] Such as image 3 , Figure 4 As shown, the pipeline electric heater includes a tubular shell 2, the two ends of the shell are provided with connecting flanges for connecting with the pipeline, and a plurality of the above-mentioned electric heating elements 1 are axially arranged in the shell; each electric heating el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com