Precast concrete block, system and building method of fast-assembled green vegetation retaining wall

A prefabricated concrete and green planting technology, applied in the fields of botanical equipment and methods, architecture, underwater structures, etc., can solve the problems of construction defects, hidden safety hazards in construction quality, long construction period of retaining walls, etc., to reduce consumption, The effect of reducing the amount of work and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0055] The prefabricated concrete block (abbreviated as prefabricated concrete block) of the present invention is an integral prefabricated concrete structure, and in order to further improve the tensile and compressive properties of the integral prefabricated concrete structure, it also includes steel bars and steel bars added therein. One or more of mesh, steel plate or other tensile materials.

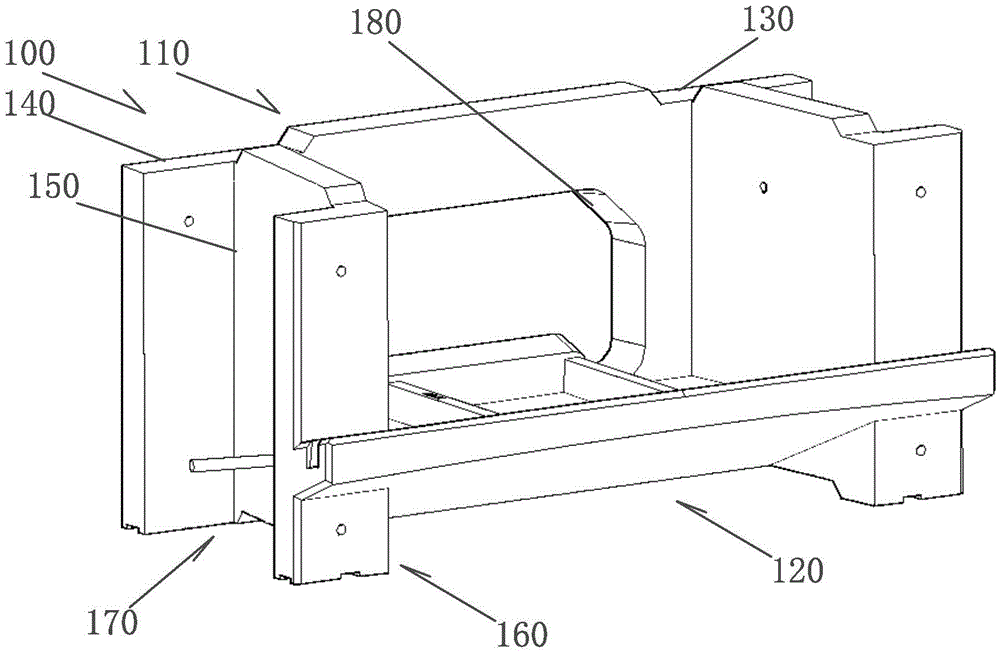

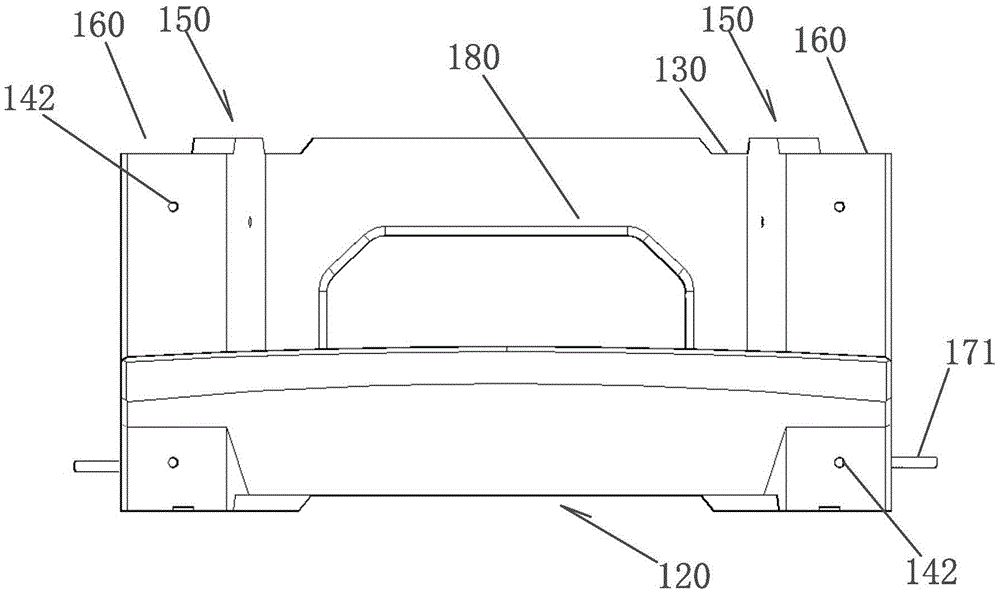

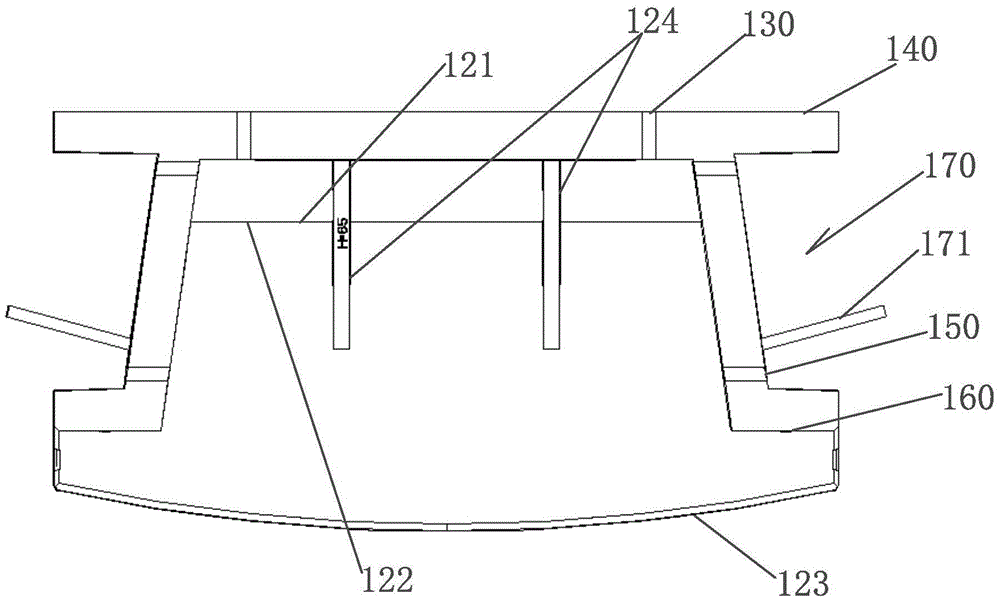

[0056] Such as figure 1 As shown, the prefabricated concrete block 100 for quickly assembling the green vegetation retaining wall includes a vertical vegetation channel 110, and is fixed in the vegetation channel 110, a vegetation board 120 intersecting with the axis of the vegetation channel 110, and the vegetation channel 110. The bottom wall 130 of the groove extends to both sides (left and right), and the extension parts 140 of the vegetation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com