Locknut looseness preventing device

A lock nut and anti-loosening technology, which is applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of lock nuts with multiple spaces, unreliable anti-loosening, and high failure rate, and achieve the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

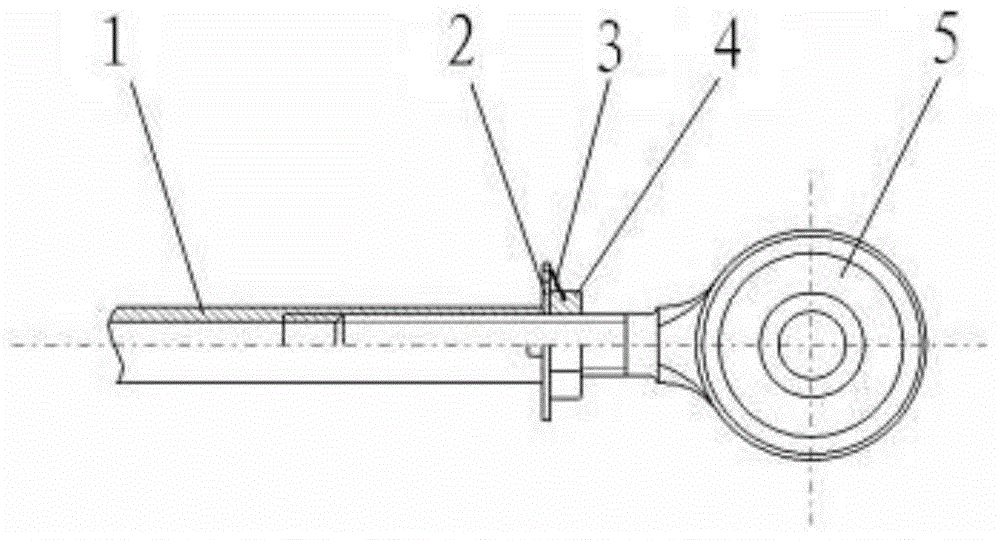

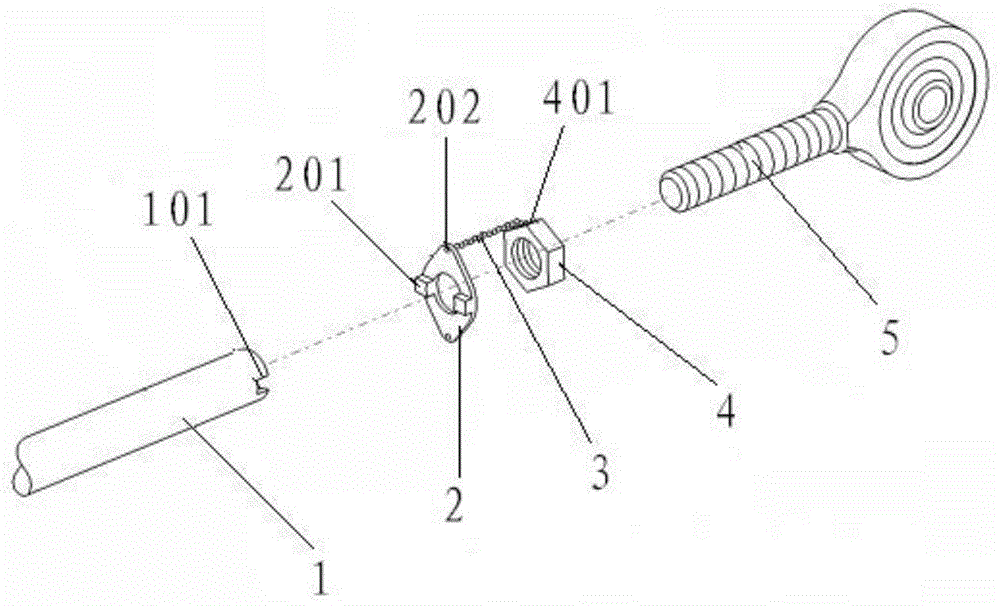

[0009] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings. The first embodiment of the present invention provides a lock nut anti-loosening device, including a base 1, a threaded rod 5, and a lock nut 4. It is characterized in that it also includes Lock ring 2 and fuse 3. Internal threads are processed on the base body 1, and key grooves 101 are processed on the ends thereof. A key 201 is processed on the lock ring 2 to match with the key groove 101 on the base 1 . Align the center hole on the lock ring 2 with the center line of the internal thread on the base 1 , and insert the key 201 on the lock ring 2 into the key groove 101 on the base 1 . Screw the lock nut 4 onto the external thread of the threaded rod 5 . Screw the threaded rod 5 into the internal thread on the base body 1 after passing through the central hole on the lock ring 2 . Rotate the threaded rod 5 to make it reach a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com