UHMWPE pipe extruder cooling line pressure relief valve

An ultra-high molecular weight, cooling pipeline technology, applied in the field of cooling pipeline pressure relief valve of ultra-high molecular weight polyethylene pipe extruder, can solve the problems of expansion and deformation of the cooling pipeline, affecting the normal operation of production, temperature rise, etc., to avoid Expansion burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

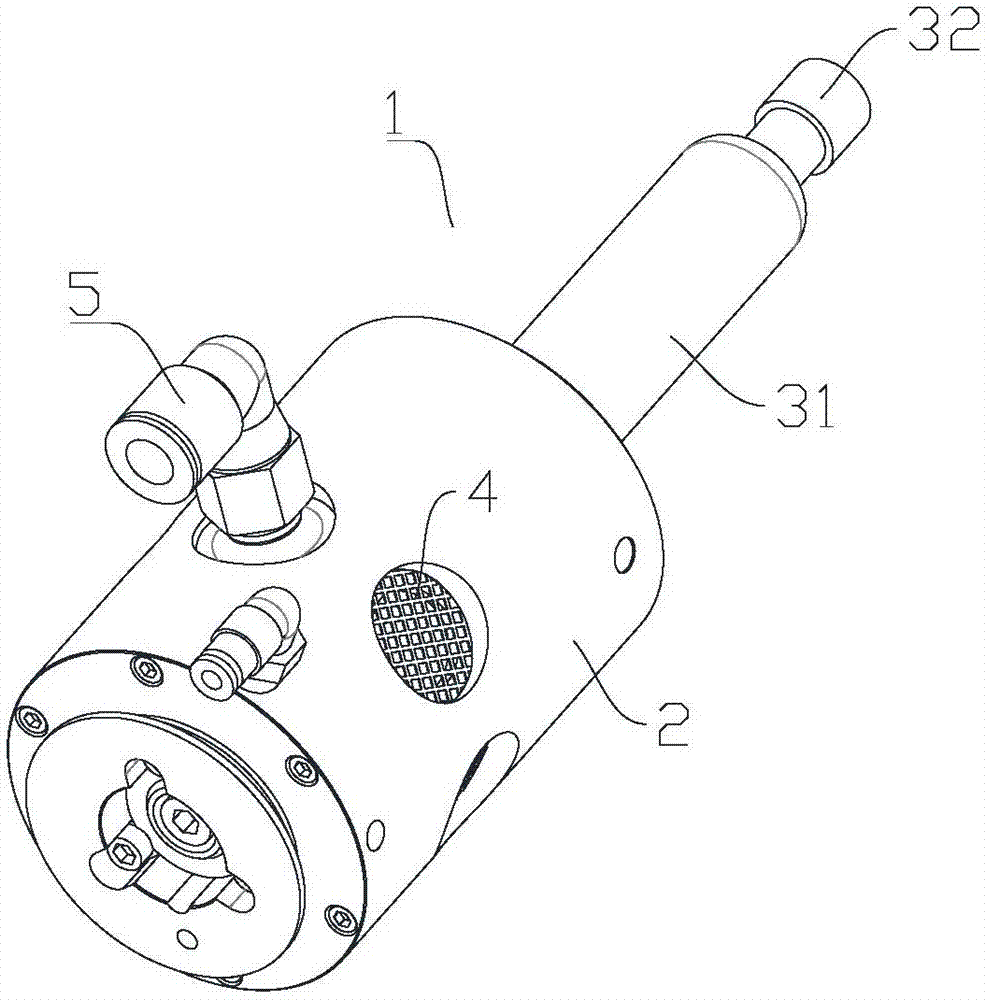

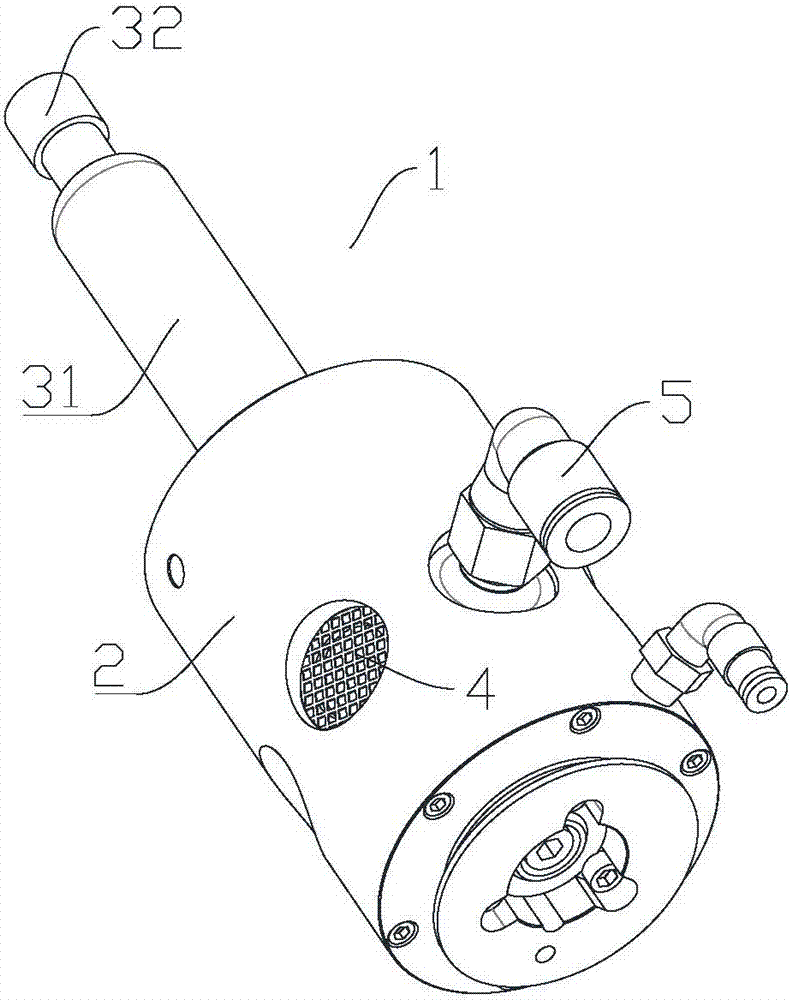

[0013] The invention provides a pressure relief valve capable of rapidly reducing the internal pressure of a cooling pipeline under high temperature and high pressure.

[0014] Such as figure 1 , figure 2 As shown, an ultra-high molecular weight polyethylene pipe extruder cooling pipeline pressure relief valve 1 includes a cooling pipeline connector 2, and a first air pressure telescopic rod 31 is arranged on the cooling pipeline connector 2 , the first air pressure telescopic rod 31 is also provided with a second air pressure telescopic rod 32, and a plurality of steam outlets 4 and exhaust pipes 5 are also provided on the cooling pipeline con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap