Vehicle roof trunk

A luggage and box body technology, applied in the luggage field, can solve the problems of easy safety accidents, inconvenience and cumbersomeness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

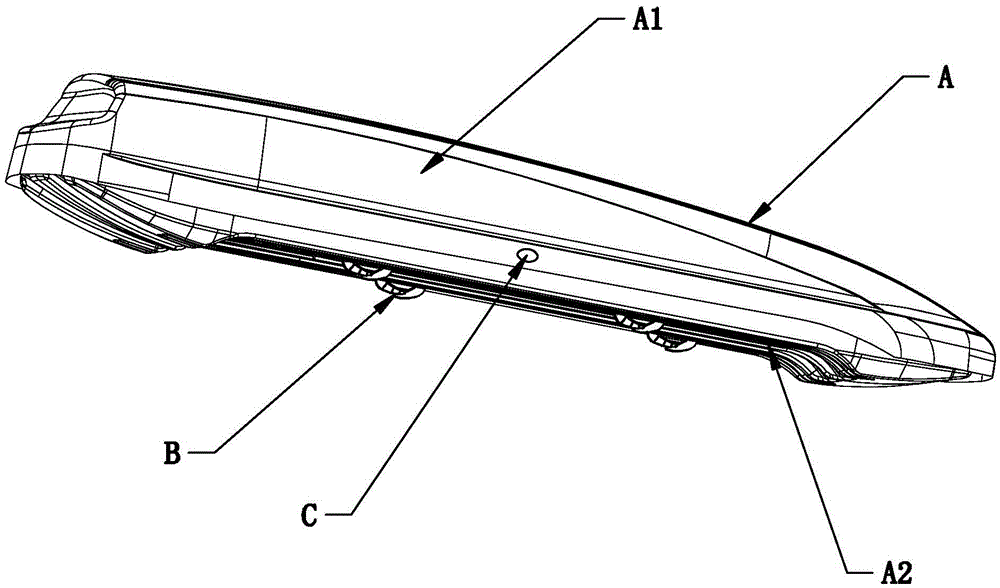

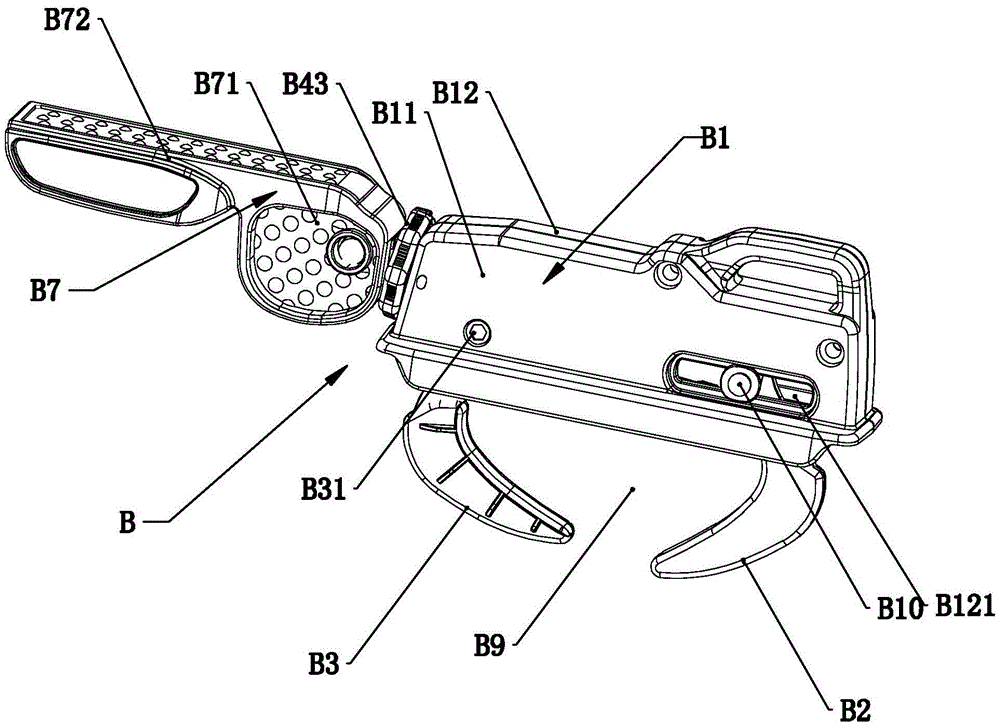

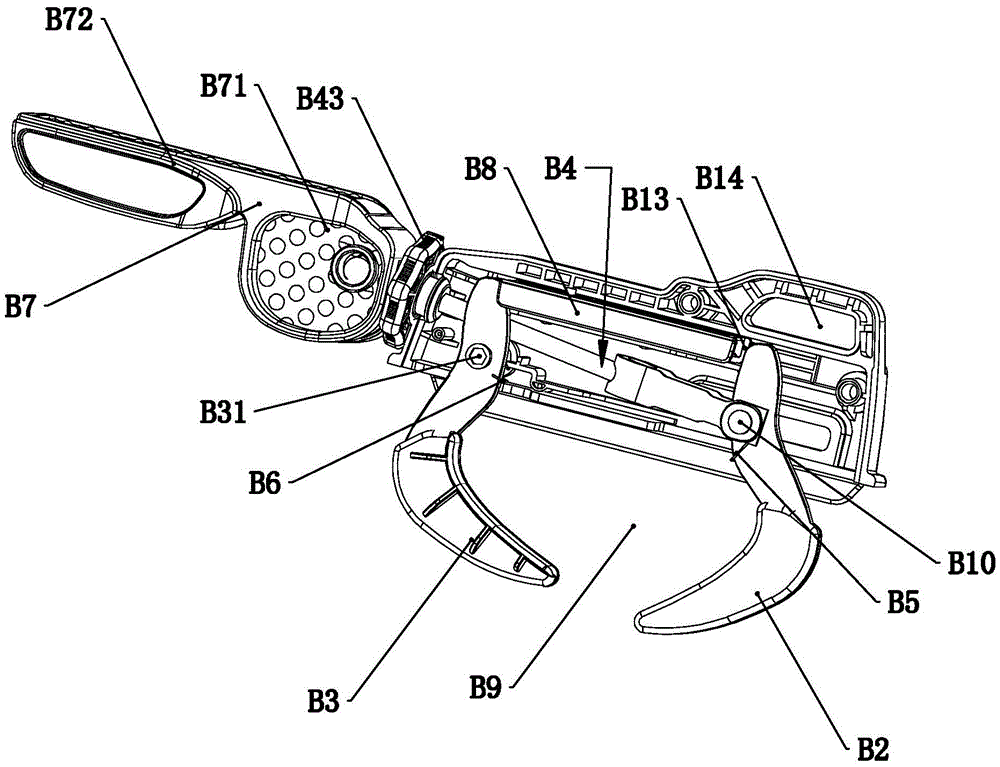

[0024] Such as figure 1 — Figure 15As shown, a roof box includes a box body A, a quick connector B arranged on the box body A, and a lock C for the roof box body. The box body A includes an upper box body A1 and a lower box body A2 , the lower box body A2 is provided with a through hole, the quick connector B is arranged at the position of the through hole, the lower ends of the first handle B2 and the second handle B3 of the quick connector B protrude from the through hole, The quick connector B includes a housing B1, a first handle B2, a second handle B3, a pull rod B4, a first torsion spring B5, a second torsion spring B6, an eccentric wheel handle B7 and a support rod B8. The upper ends of the first gripper B2 and the second gripper B3 are set inside the housing B1, the lower ends of the first gripper B2 and the second gripper B3 are located outside the housing B1 to form a clamping area B9, and one end of the pull rod B4 Hinged to the upper end of the first handle B2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com