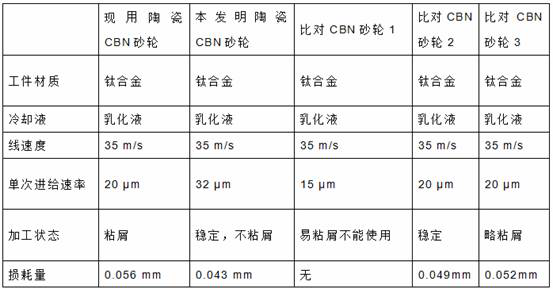

Hot-pressed high-strength ceramic cbn grinding wheel for grinding aerospace titanium alloy and preparation method thereof

An aerospace and titanium alloy technology, applied in the field of grinding, can solve the problems of reducing the content of binders and poor fluidity of high-strength binders, and achieve the effects of improving edge rate, sharpness, and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

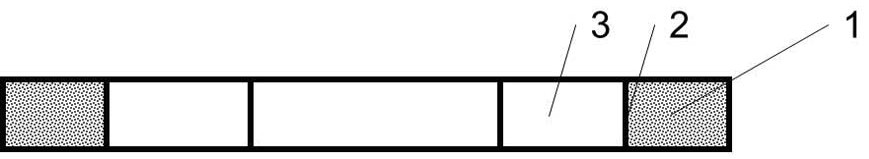

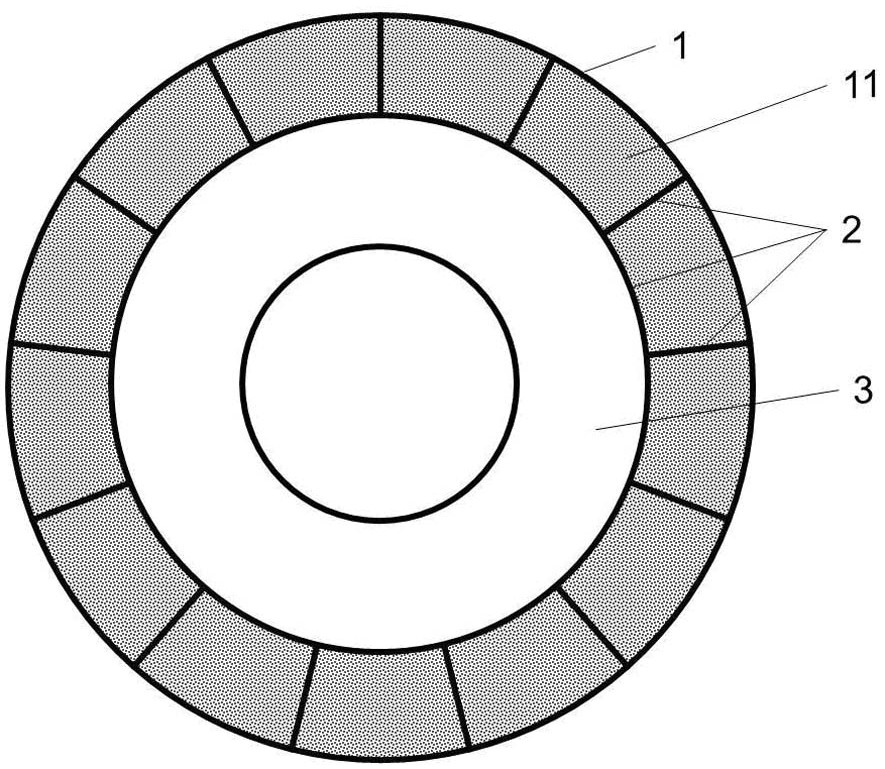

[0034] The steel matrix of the grinding wheel is conventionally heat-treated before use, and the required shape is fine-turned for the bonding of ceramic CBN grinding wheel blocks, which is a conventional method.

[0035] The ceramic CBN grinding wheel block is prepared from CBN abrasive, vitrified bond, white corundum and phenolic resin powder. Concrete preparation process is as follows:

[0036] (1) Weigh silicon dioxide, borax, aluminum oxide, titanium dioxide, and barium oxide according to the weight percentage of 53:27:6:10:4, and mix them well; then put the mixture into a frit furnace at 1550 °C Carry out conventional smelting; then water-cool the smelted mixture and grind it into powder with a ball mill; finally dry it through a 60-mesh sieve to obtain the required vitrified bond;

[0037] (2) Weigh the CBN abrasive, the above vitrified bond, white corundum and phenolic resin powder according to the weight percentage of 73:12:10:5, and mix them thoroughly; the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com