A kind of heavy oil viscosity reducer and preparation method thereof

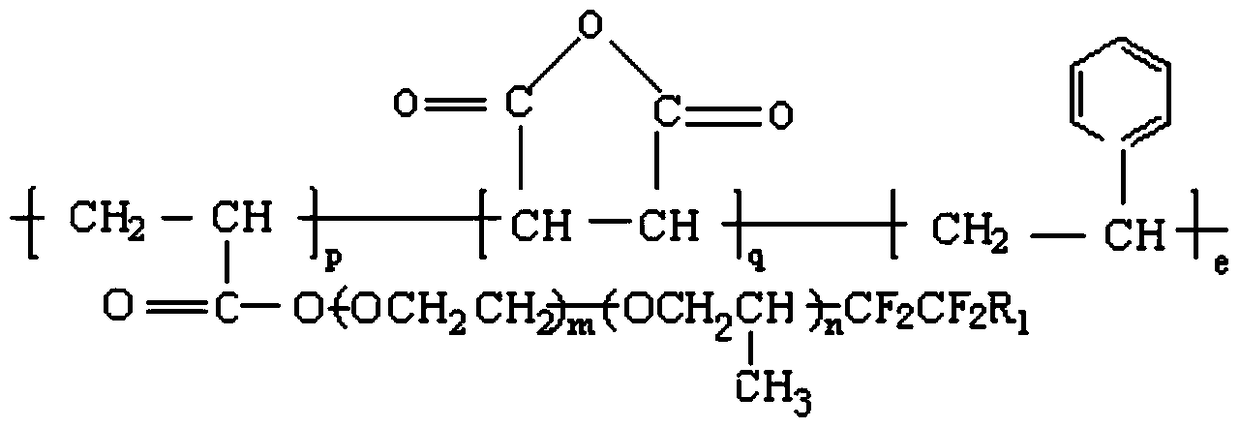

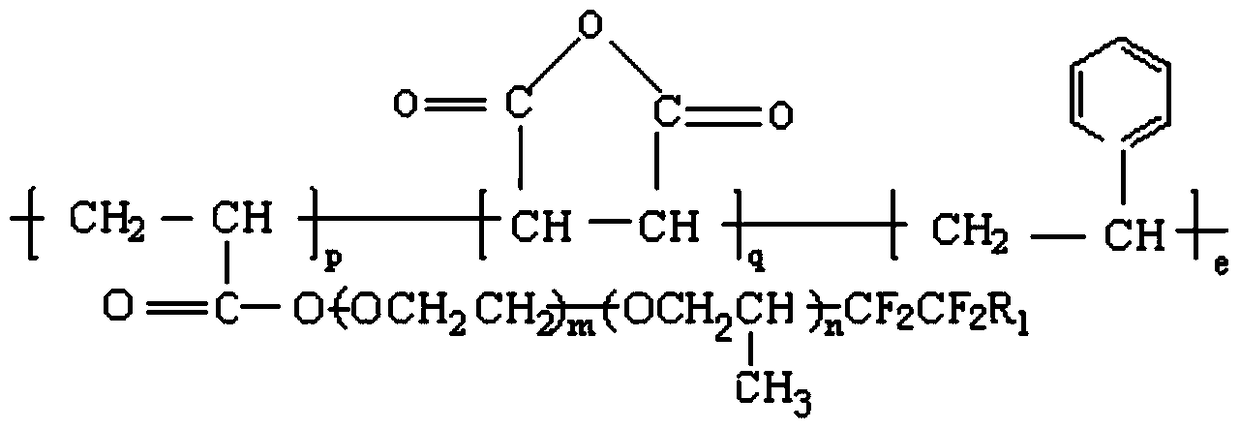

A thick oil viscosity reducer and viscosity reducer technology, applied in the heavy oil viscosity reducer and its preparation, the preparation of super heavy oil viscosity reducer, heavy oil field, can solve the problem of single molecule, complex preparation process and small application range and other problems, to achieve the effect of high viscosity reduction rate and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the binder is as follows:

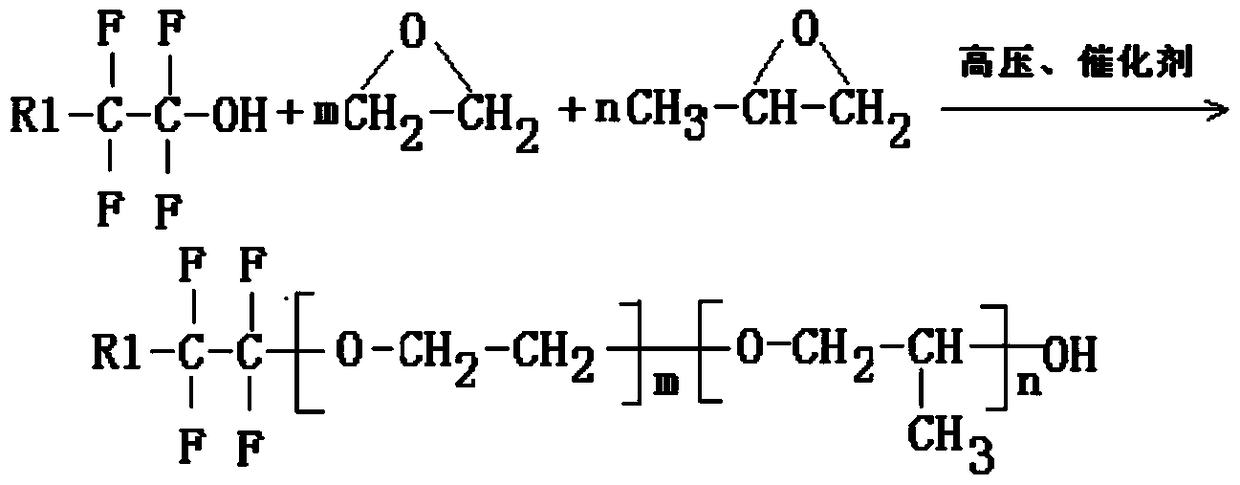

[0049] (1) Synthesis steps of fluorocarbon alcohol ether:

[0050] Transfer the fluorocarbon alcohol into the high pressure reactor, vacuum to about -0.08~-0.1Mpa, extract the catalyst boron trifluoride ether, turn on the stirring and raise the temperature to 60~70℃, start to enter the propylene oxide, and age for 30 minutes after the reaction; The pressure drops to 0MPa, the temperature drops to 120°C, the catalyst is added with boron trifluoride ether, and ethylene oxide is continued. The reaction temperature is controlled at about 125~135°C, and the pressure is less than 0.1MPa. Material, the fluorocarbon alcohol ether mixture is obtained. The reaction formula is as follows:

[0051]

[0052] In the formula: R1 is a C6-28 normal alkyl group.

[0053] (2) Synthesis of fluorocarbon ether acrylate:

[0054] In the reactor equipped with condenser, stirrer and thermometer, add fluorocarbon ether and polymerization inhibitor h...

Embodiment 1

[0075] (1) Synthesis of fluorocarbon alcohol ether:

[0076] Transfer 120g of fluorocarbon alcohol to high pressure reactor, vacuum to -0.09Mpa, extract catalyst, turn on stirring and raise temperature to 65℃, start to feed in propylene oxide, end the reaction and age for 30 minutes; pressure drops to 0MPa, temperature drops to 120℃ Add 5 g of the catalyst boron trifluoride ether, continue to feed ethylene oxide, the reaction temperature is controlled at about 130 ℃, the pressure is less than 0.1MPa, the feed is aged for 30 minutes, the temperature is discharged, and the fluorocarbon ether mixture is obtained. The reaction formula is as follows:

[0077]

[0078] In the formula: R1 is a C6-28 normal alkyl group.

[0079] (2) Synthesis of fluorocarbon ether acrylate:

[0080] Weigh 11g acrylic acid, 27g fluorocarbon ether mixture, and 0.1g polymerization inhibitor hydroquinone; add the fluorocarbon ether mixture into a three-necked flask equipped with a thermometer, mechanical stirrer...

Embodiment 2

[0087] (1) Synthesis of fluorocarbon alcohol ether:

[0088] Transfer 120g of fluorocarbon alcohol to high pressure reactor, vacuum to -0.08Mpa, extract catalyst, turn on stirring and increase temperature to 65℃, start to feed in propylene oxide, and age for 30 minutes after the reaction; pressure drop to 0MPa, temperature drop to 120°C Add 5 g of the catalyst boron trifluoride ether, continue to feed ethylene oxide, the reaction temperature is controlled at 135°C, the pressure is less than 0.1MPa, the feed is aged for 30 minutes, the temperature is discharged, and the fluorocarbon ether mixture is obtained. The reaction formula is as follows:

[0089]

[0090] In the formula: R1 is a C6-28 normal alkyl group.

[0091] (2) Synthesis of fluorocarbon ether acrylate:

[0092] Weigh 11g acrylic acid, 27g fluorocarbon ether mixture, and 0.1g polymerization inhibitor hydroquinone; add the fluorocarbon ether mixture into a three-necked flask equipped with a thermometer, mechanical stirrer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com