Thickened oil viscosity reduction oil washing agent for synergistic polymer flooding as well as preparation method and application of thickened oil viscosity reduction oil washing agent

A viscous detergent and polymer technology, which is applied in the field of synergistic polymer flooding heavy oil viscosity-reducing detergent and its preparation, can solve the problems of unresolved polymer compounding and improve heavy oil recovery High efficiency, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

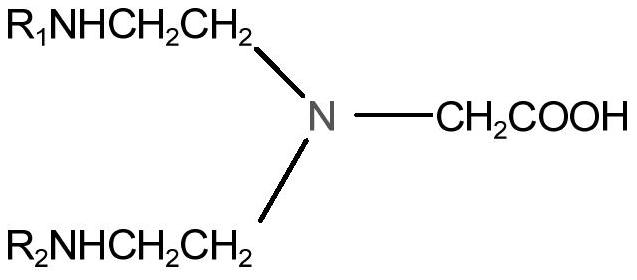

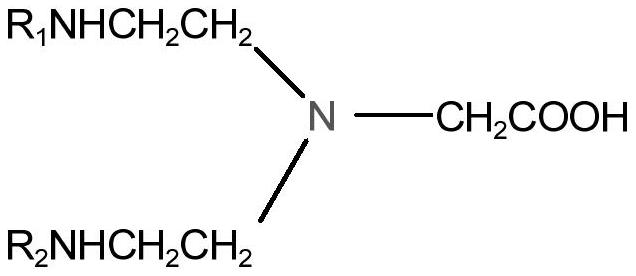

Method used

Image

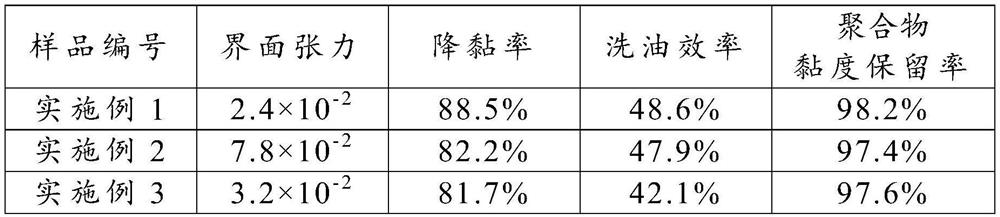

Examples

Embodiment 1

[0028] In the reaction vessel, successively add sodium lauryl isethionate 35g, ɑ-iminoacetic acid 30g (R 1 =8, R 2 = 8), 20 g of fatty alcohol polyoxyethylene ether glucoside (n = 10, R = 12), 10 g of ethanol and 5 g of water, and stirred evenly at 50° C. to obtain a heavy oil viscosity-reducing oil wash for synergistic polymer flooding .

Embodiment 2

[0030] In the reaction vessel, successively add sodium cocoyl isethionate 35g, ɑ-iminoacetic acid 20g (R 1 =10, R 2 =8), 10 g of fatty alcohol polyoxyethylene ether glucoside (n = 12, R = 13), 15 g of methanol and 20 g of water, and stirred uniformly at 50° C. to obtain a heavy oil viscous-reducing and washing oil for polymer flooding.

Embodiment 3

[0032] In the reaction vessel, successively add sodium dodecylbenzenesulfonate 25g, ɑ-iminoacetic acid 30g (R 1 =12, R 2 =8), 10 g of fatty alcohol polyoxyethylene ether glucoside (n = 13, R = 14), 10 g of isopropanol and 25 g of water, and stirred evenly at 50° C. to obtain a heavy oil for polymer flooding, viscosity-reducing and washing oil .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com