Suction disc type building block corrector

A technology of building blocks and suction cups, which is applied in construction, building structure, and processing of building materials, etc., and can solve problems affecting project quality and heavy workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

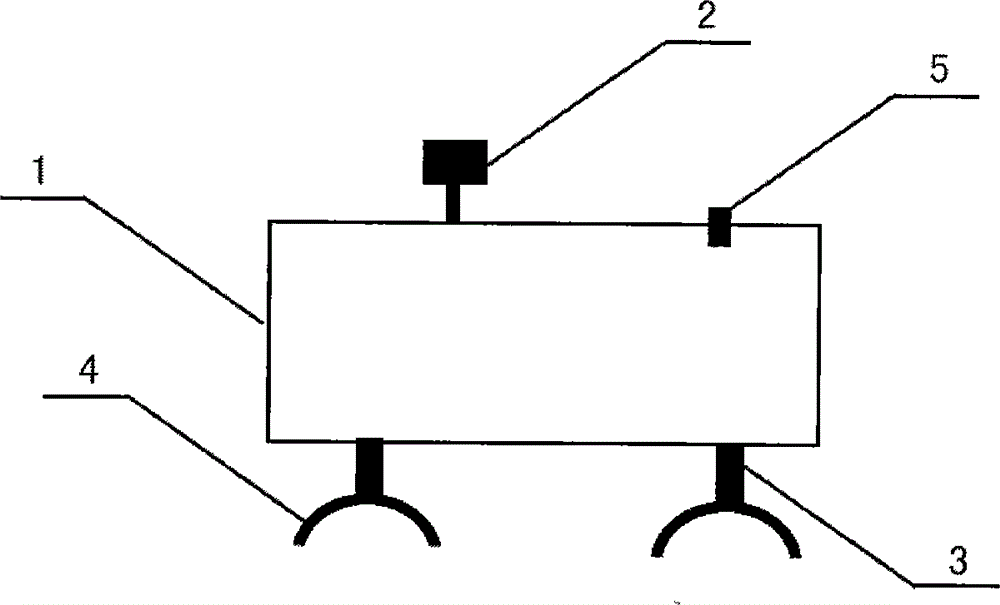

[0012] Embodiment: as shown in the accompanying drawing. The suction cup type building block corrector includes a frame [1], an infrared block corrector [2] is set on the frame, a frame body [3] is set at the bottom of the frame, and several suction cups are set on the frame body [4], when in use, the frame is fixed to the existing wall by the suction cup, and the block is corrected by the infrared block corrector [2].

[0013] The suction cup type building block corrector, the frame body [3] can be extended and twisted, and the correcting base for blocks in different positions can be determined.

[0014] Suction cup type building block corrector, infrared block corrector [2] has a variety of color light prompt modes.

[0015] Suction cup type building block corrector, set prompt module [5], provide operation prompt in multiple modes when needed.

[0016] Suction cup type building block corrector, the block corrector adopts rechargeable DC power supply.

[0017] The above-m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap