An Anchor Cable Supporting Method with Repeatedly Applied Prestress

An anchor cable support and prestressing technology, which is used in earth-moving drilling, bolt installation, mining equipment, etc. Structure and other problems, to prevent loosening or failure, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

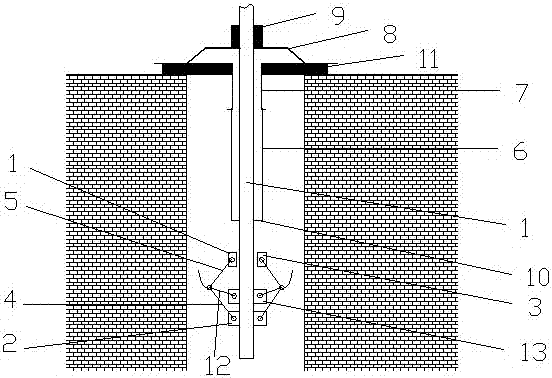

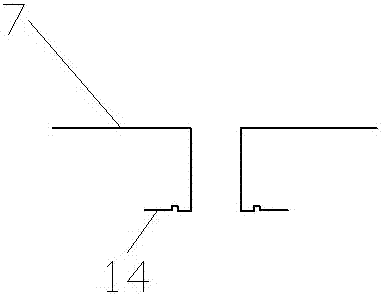

[0023] Example 1: Combining Figure 1-2 As shown, the anchor cable of the present invention is a prestressed anchor cable support method that can be repeatedly applied without disturbing the grouting body. The anchor cable includes: anchor cable body 1, anchoring end anchoring device, casing 6. Pressure pipe 7, supporting plate 8, lock 9, and grout stopper 10. The anchoring device at the anchoring end includes a first fixed block 2, a sliding block 3, a hook wing 5, a first support rod 4, and a first fixed block 2 Fixed on the inner end of the anchor cable body 1 deep into the borehole, the sliding block 3 is slidably arranged on the rod body of the anchor cable body 1 between the casing 6 and the first fixed block 2, and the casing 6 is arranged at a certain distance from the upper end of the sliding block 3 place, so that the sliding block 3 has enough sliding telescopic distance when the anchor cable goes deep into the borehole, so that the anchor cable goes deep into the b...

Embodiment 2

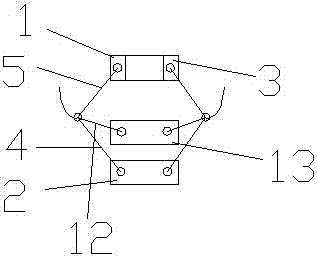

[0028] Example 2: Combining image 3 As shown, the anchoring device at the anchoring end in Embodiment 1 is further improved, and other parts are the same as Embodiment 1. In addition to the first fixed block 2, the sliding block 3, the hook wing 5, and the first support rod 4, the anchoring device at the anchoring end also includes a second fixed block 13 and a second support rod 12, and one end of the second support rod 12 is hingedly connected On the hinge point of the first support rod 4 and the hook wing 5 , the other end is hingedly connected to the second fixed block 13 . By adding the second support rod 12 and the second fixing block 13, the hook wing 5 can have enough supporting force to make the hook wing 5 lean against the hole wall. At the same time, when the anchoring end is grouted and anchored, the second support rod 12, The second fixing block 13 also provides stronger anchoring force integrated with the grout.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com