Deboost hook used for maintenance and installation of heating module

A technology of pull-back and heat-generating materials, which is applied in the field of pull-back hooks, can solve problems such as broken edge of the module's force point, easy to scratch the surface of the module, and low bearing capacity, and achieve superior hitting resistance, excellent hand feeling, and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

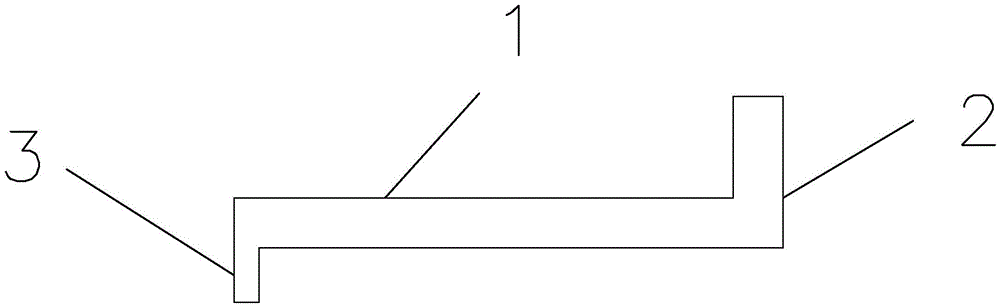

[0019] Example 1: see figure 1 , the small back bend of the present invention adopts thinning treatment, so the thickness of the small back bend is thinner, which solves the problem that the expansion joint reserved in the installation process is too small, and the pull back hook cannot be inserted. When the wooden heating module is installed or maintained , place the small back bend in the gap between the wooden heating module and the wall, adjust the angle of the small head bend, and use a hammer or other hammer to hit the big head bend of the pull back. Since there are scales on both sides of the hook body, then During construction, the scale is used to facilitate the grasp of each construction force point and the measurement of each penetration into the heating module, so as to ensure the accuracy of construction and achieve the purpose of installing and maintaining the wooden heating module.

Embodiment 2

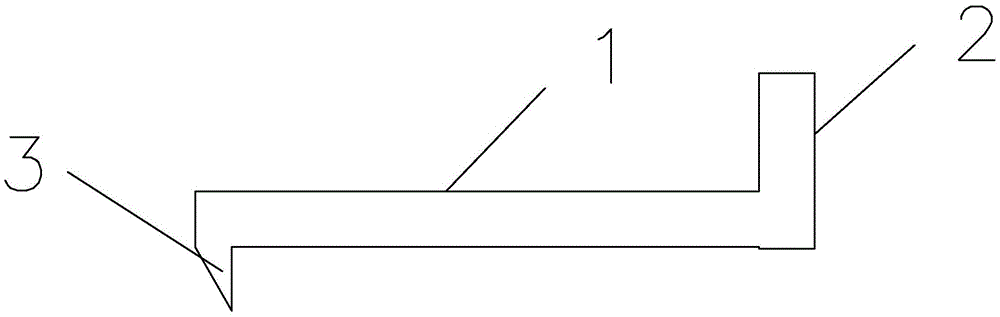

[0021] see figure 2 , the small back bend of the present invention adopts oblique treatment, and the side of the small back bend is an inclined structure, which is more convenient to place the small back bend in the gap between the board and the wall, and solves the problem of excessively reserved expansion joints during the installation process. Small, the problem that the return hook cannot be inserted. When installing or maintaining the wooden heating module, place the small return hook in the gap between the wooden heating module and the wall, adjust the angle of the small return hook, and use a hammer or other knocking parts to tap Hitting the big head bend of the return force, because there are scales on both sides of the hook body, during construction, it is convenient to grasp the force point of each construction and the size of each penetration into the heating module through the scale, so as to ensure the accuracy of construction and achieve the accuracy of wood The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com