Composite threaded gauge achieving rapid detection

A thread gauge and thread technology, which is applied in the field of rapid detection of compound thread gauges, can solve the problems of unfavorable work intensity and inspection efficiency of inspectors, inconvenient management of on-site tooling, and increased number of inspection tools, so as to improve measurement efficiency and reduce the number of inspection tools , the effect of reducing the screw-in length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

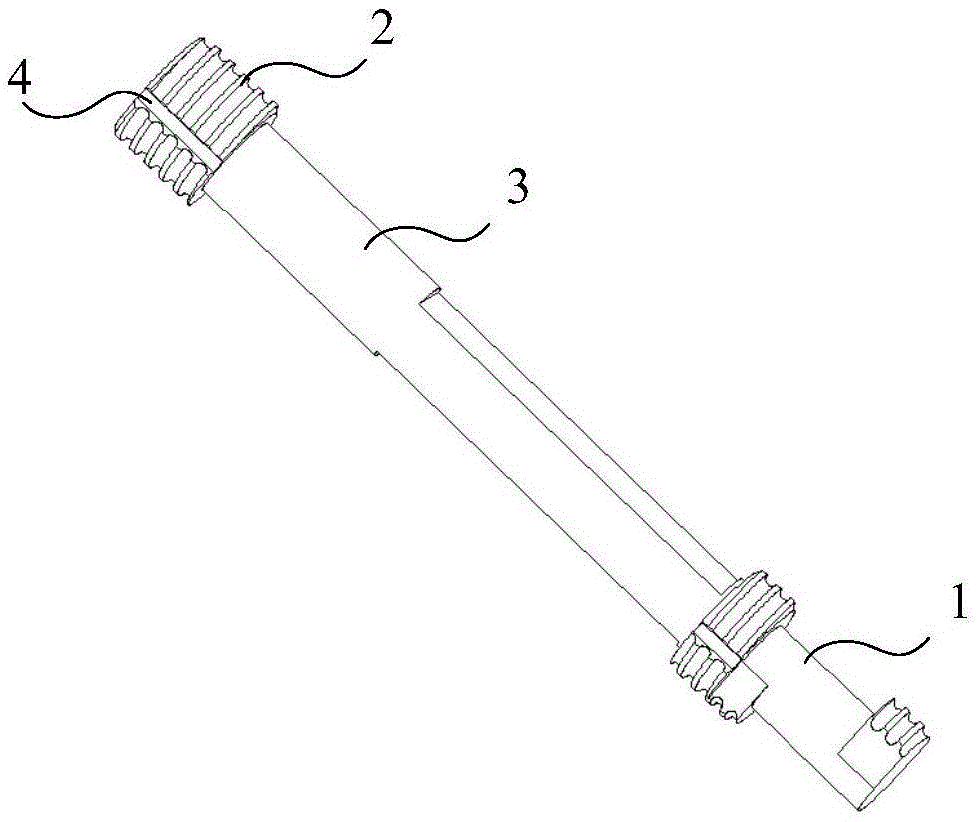

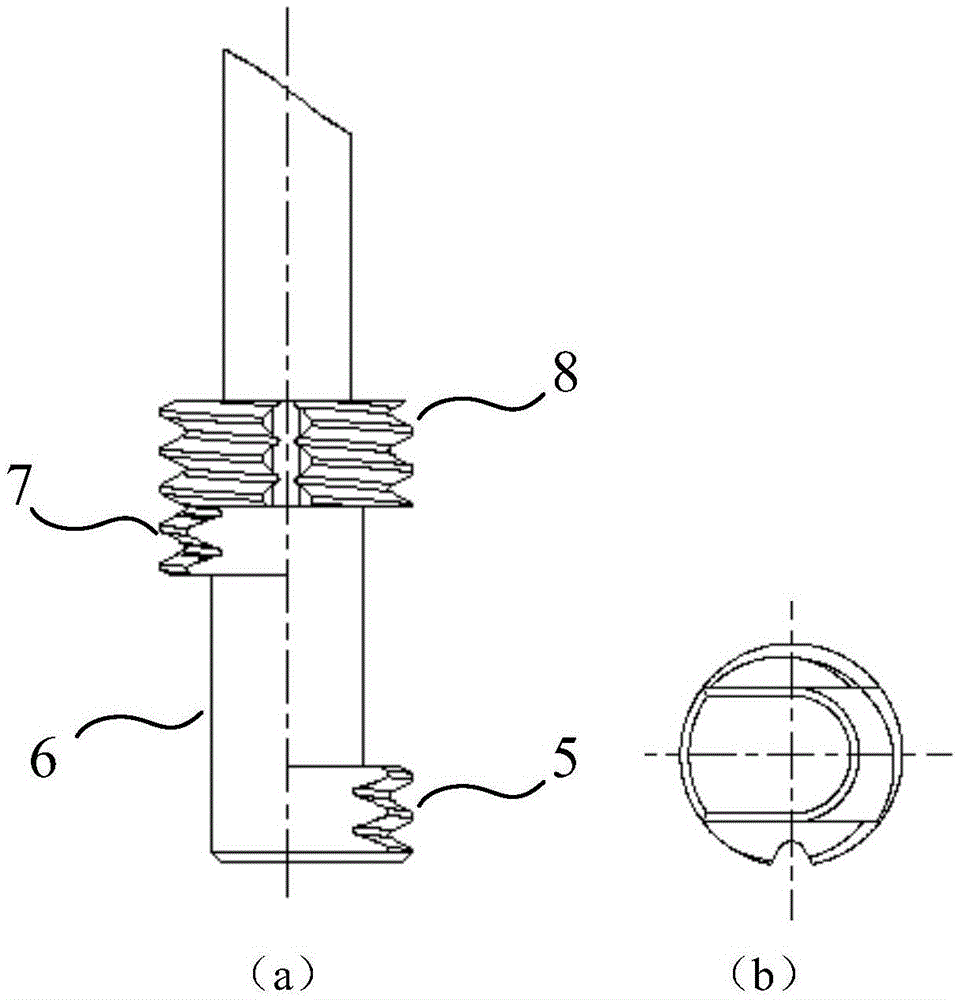

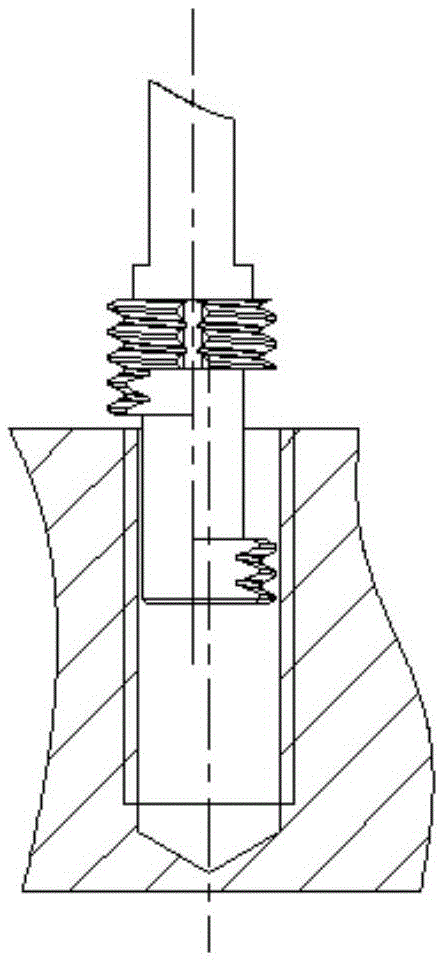

[0022] see figure 1 and figure 2 , the present invention includes a shank 3, the front end of the shank 3 is a through end 1, the rear end is a stop end 2, and the outside of the stop end 2 is provided with threads to form a thread stop gauge; the outside of the pass end 1 is provided for reducing the The two sections of thread that are screwed together are enough to form a thread gauge; the side of the shank 3 is milled with two opposite planes, one is printed on the scale for observing the depth of the threaded hole to be inspected, and the other is printed for the tooling number , no-go end identification and thread specifications to be checked. The threads of the through end 1 and the stop end 2 are provided with plug gauge chip pockets 4 . The thread gauge includes the end thread 5, the middle polished rod 6 and the end thread; the end thread 5 is an incomplet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com