Full-scale mistake proofing go and no-go gauge

A pass-and-stop, full-scale technology, applied in the field of aluminum profile frames, can solve the problems of long detection time, low detection accuracy, large financial and human consumption, and achieve cost-effective, low-cost, and easy-to-carry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

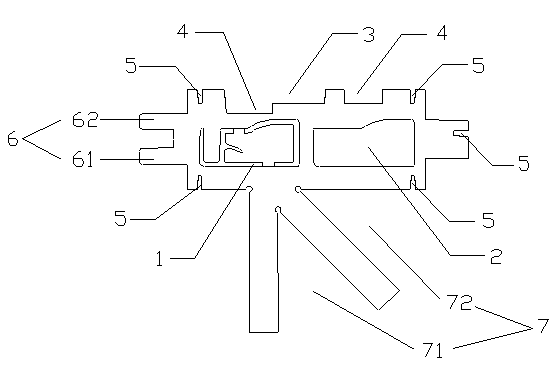

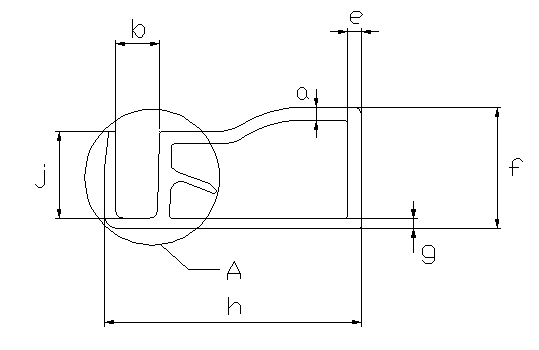

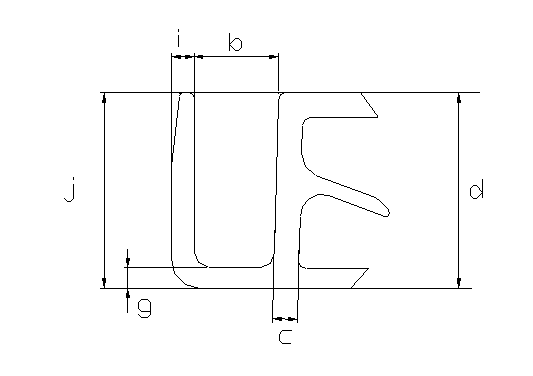

[0033] see figure 1 , the present invention relates to a full-size error-proof go-no-go gauge, which includes a go-no-go gauge body, inside the go-no-go gauge body is provided with a marking groove 1 and a hollow area 2, and the marking groove 1 is used to mark the full-size The cross-section of the profile that can be detected by the go-no-go gauge, the hollow area 2 is a profiling hole, which is used to detect the upper limit of the outer frame size of the profile cross-section, and the outer edge of the go-no-go gauge body is provided with multiple sets of profile width detection grooves 3. Profile height detection groove 4, profile wall thickness detection groove 5, profile opening width detection bump 6 and angle detection card angle 7, the profile width detection groove 3 is used to detect the upper and lower limits of the profile width, and the profile height detection Groove 4 is used to detect the upper and lower limits of the profile height, and the profile wall thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com