A Checking Tool for Measuring Valve Disk Cone Height

A valve disc cone and height technology, used in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of short time for designing and manufacturing common special inspection tools, short valve design and change cycle, unfavorable quality control, etc., and achieve disputes. Less, faster measurement readings, and the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

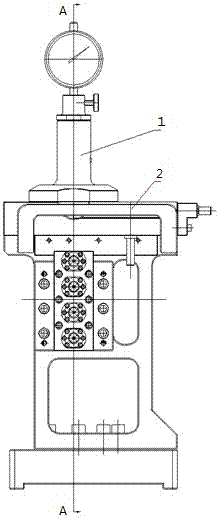

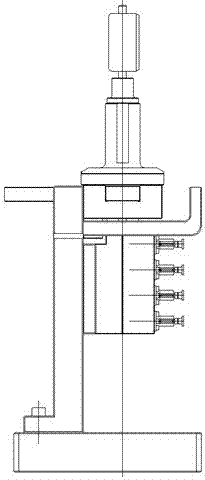

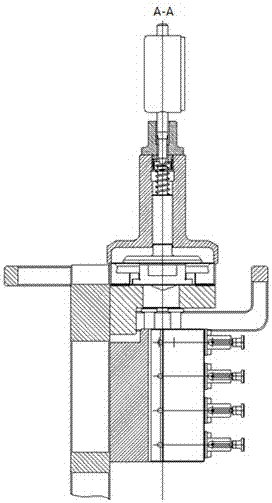

[0063] Embodiment 1, a test tool for measuring the height of a valve disc cone, including a measuring assembly with a dial indicator, base assembly parts and pressing parts, a dial indicator, a first locking screw, a bushing, a locking cap, a spring, Measuring sleeve, limit screw, probe shaft, base assembly part, pressing part, first hexagon socket head cap screw, slider part, vertical plate, first handle, second handle, V-shaped block assembly, base, Second hexagon socket cap screw, guide rod, slider seat, second locking screw, first guide block, adjustment screw, second guide block, slider assembly, fixing assembly, first cylindrical pin, third inner hexagon Cylinder head screw, spring pressure block, spring, second straight pin, third straight pin, fourth hexagon socket head cap screw, fifth hexagon socket head cap screw, sliding block, first insert, fixed block, second insert Block, handle, lock nut, bayonet pin, sliding sleeve, compression spring, compression shaft, compr...

Embodiment 2

[0064] Embodiment 2, according to the detection requirements of the project of the longitudinal distance from the conical surface gauge section of the internal combustion engine valve disc to the end face of the disc, first of all, it is necessary to ensure that the axis of the rod cylindrical surface of the measured valve with different rod diameters is simulated; secondly, it is necessary to ensure that different valve discs are simulated. The cross-section of the size of the cone gauge; the third requirement is that the measurement process is stable, the measurement data has good repeatability, and the reading is convenient; the fourth is the convenience of manual operation (testing can still be carried out without a platform).

[0065]The valve cone height checker is characterized in that the checker is composed of a valve cone height measuring assembly (with a dial indicator), a base assembly part and a pressing part. Wherein the base assembly part is provided with a slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com