Method and device for calculating assembly force of proton exchange membrane fuel cell stack

A technology of fuel cell stacks and proton exchange membranes, applied in computing, electrical digital data processing, computer-aided design, etc., can solve problems such as damage, affecting the performance and life of fuel cell stacks, and increasing internal resistance of stacks, and achieve Prevent the pressure from being too high or too low, fast data processing, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

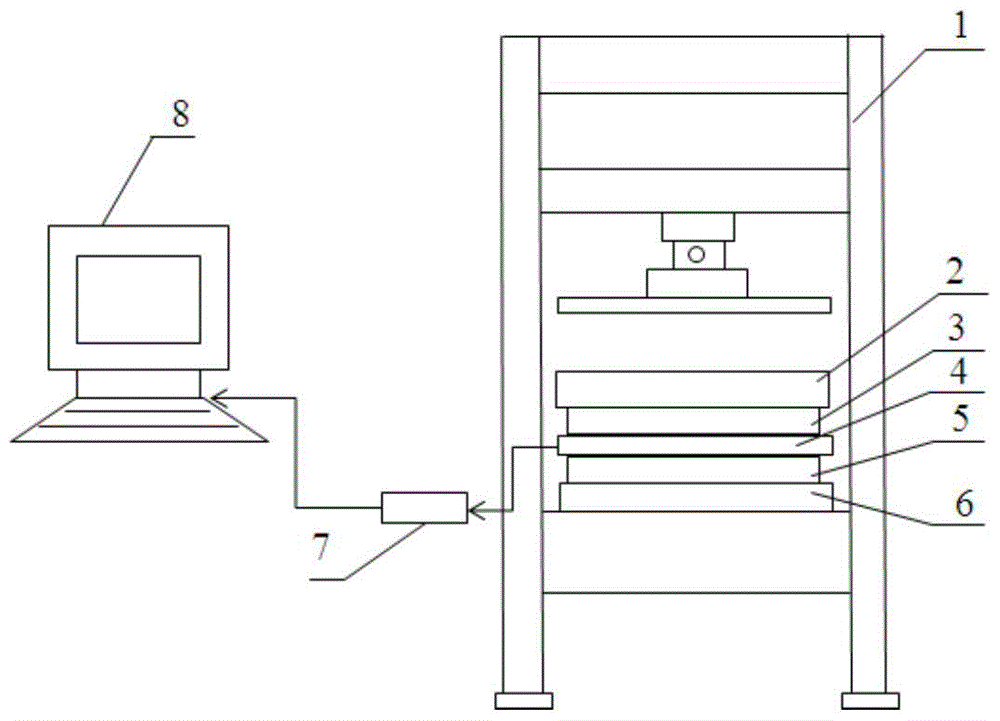

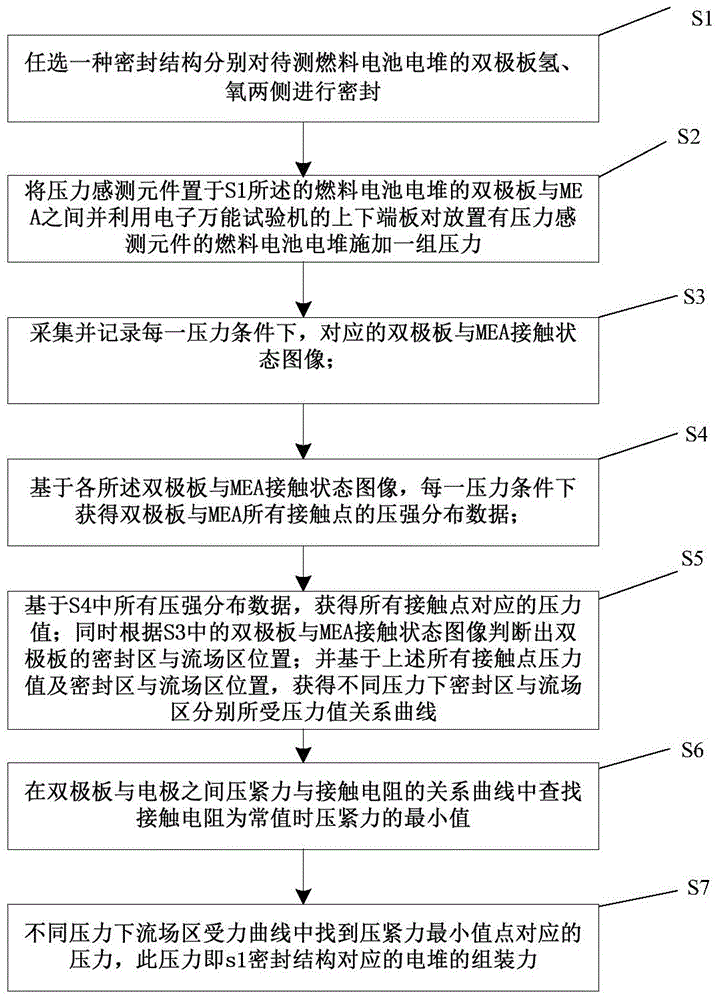

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

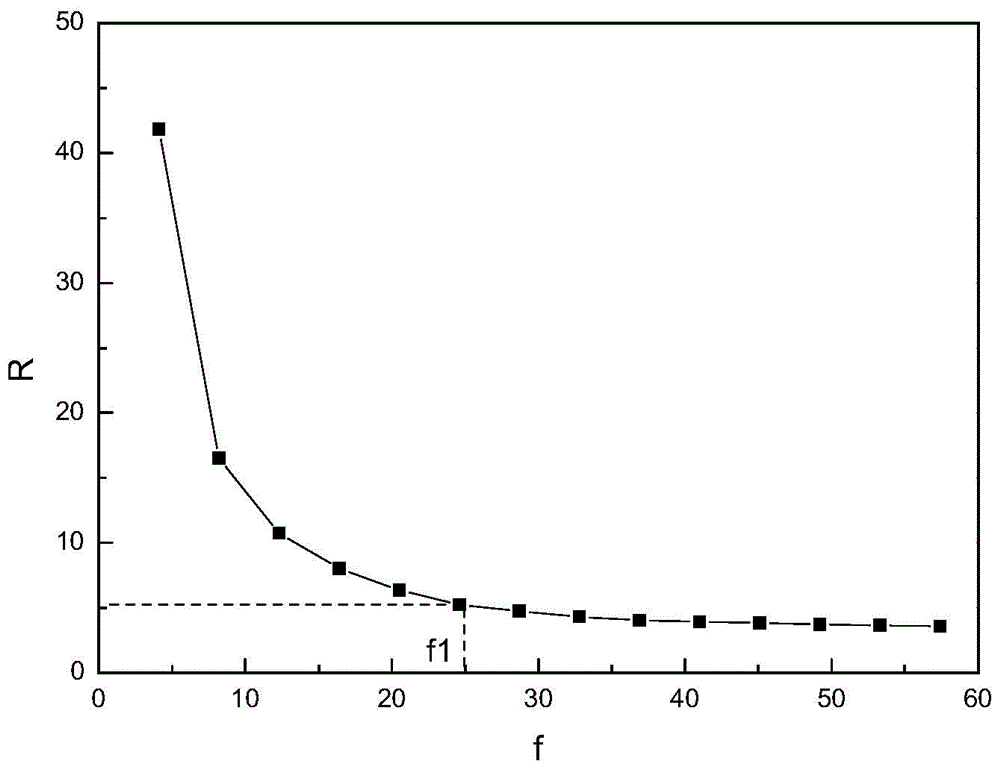

[0038] Aiming at the shortage of existing stack assembly force testing means, the present invention designs a convenient and accurate method for calculating the stack assembly force of a proton exchange membrane fuel cell, which is characterized in that the bipolar plate of a single cell under different pressures and the MEA The relationship between the force and pressure of the sealing area of the bipolar plate is obtained by the test of the indirect contact state. When the force on the sealing area is f, the assembly pressure F of the stack is obtained. The compression force and the contact resistance of the bipolar plate and the electrode are Through the test, the minimum value f of the pressing force is obtained when the contact resistance is constant, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com