Lashing bridge for a cargo ship

A technology for lashing bridges and cargo ships, which is applied in the directions of preventing multi-way movement of goods, ship accessories, ships, etc., can solve the problems of expensive, unfavorable transmission of force and load on the lashing bridge, and achieves cheap manufacturing and reduced vibration of the lashing bridge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

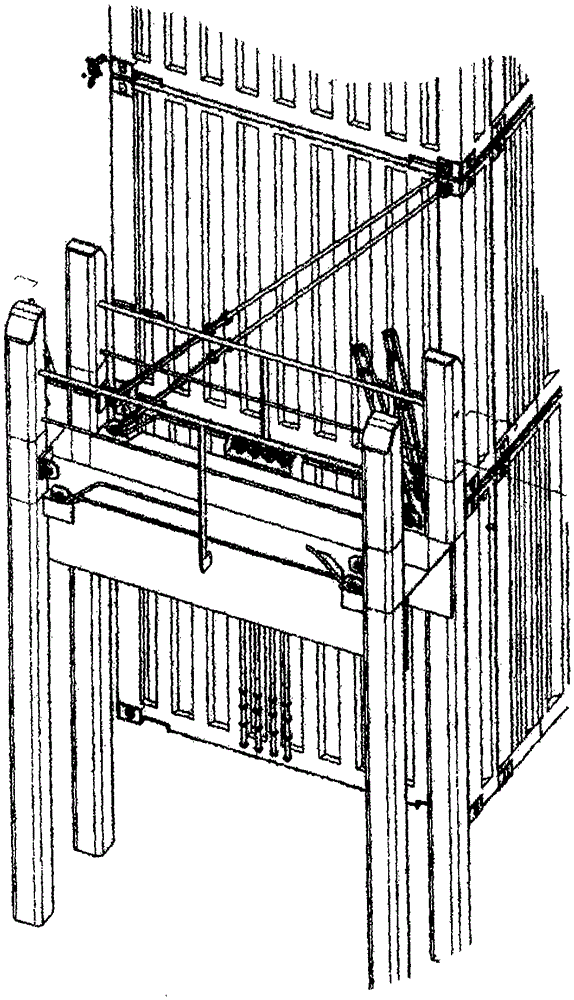

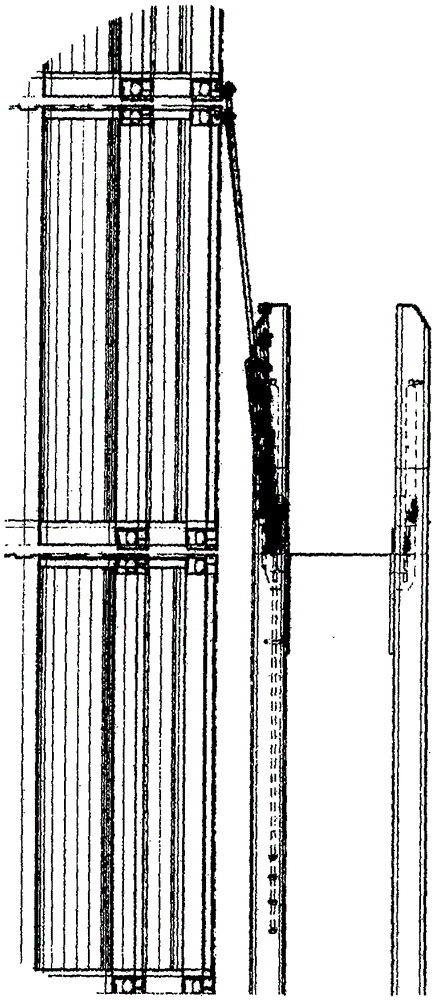

[0020] Accordingly, Figures 1-3 illustrate the prior art. These figures are shown to make it easier to understand the differences between the prior art and the present invention, which are not described in any more detail below. Figures 1 and 2 show the lashing bar (in this case with 2 units) between the lashing bridge and the stack of containers. The lack of verticality of the lashing bars seen in Figure 2 creates forces on the lashing bridge in the longitudinal direction of the ship.

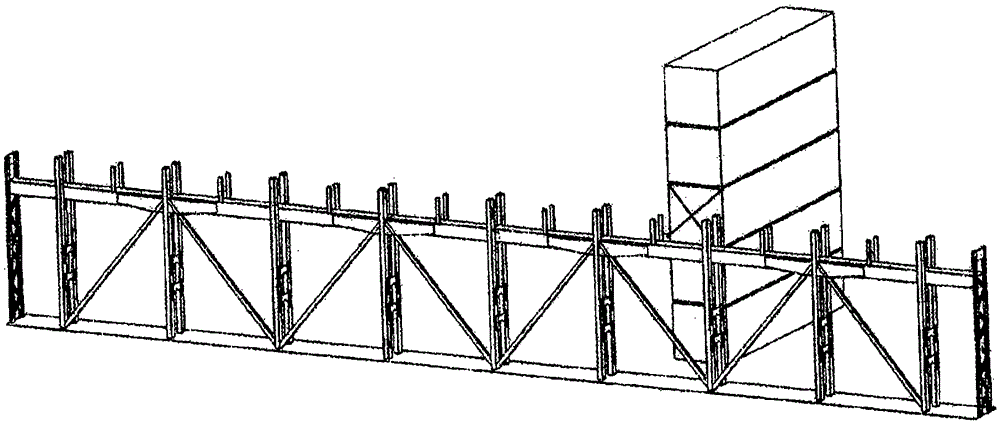

[0021] Figure 4 and Figure 5 The invention is shown. The lashing bridge 1 of a cargo ship is usually arranged along the transverse direction of the ship and the containers / container stacks 2 are arranged between them in such a way that the lashing bars 3 of the containers can be fixed between the containers 2 and the lashing bridge 1 . The lashing bridges 1 are of different heights, generally they extend from the level of the weather deck of the ship to the height of two, three or four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com