Electronic component unit and method of manufacturing the same

A technology of electronic components and manufacturing methods, applied in the field of electronic component units and their manufacturing, can solve the problems of increased viscosity of liquid resin raw materials, increased manufacturing costs, insufficient filling, etc., and achieve the effect of excellent waterproof characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

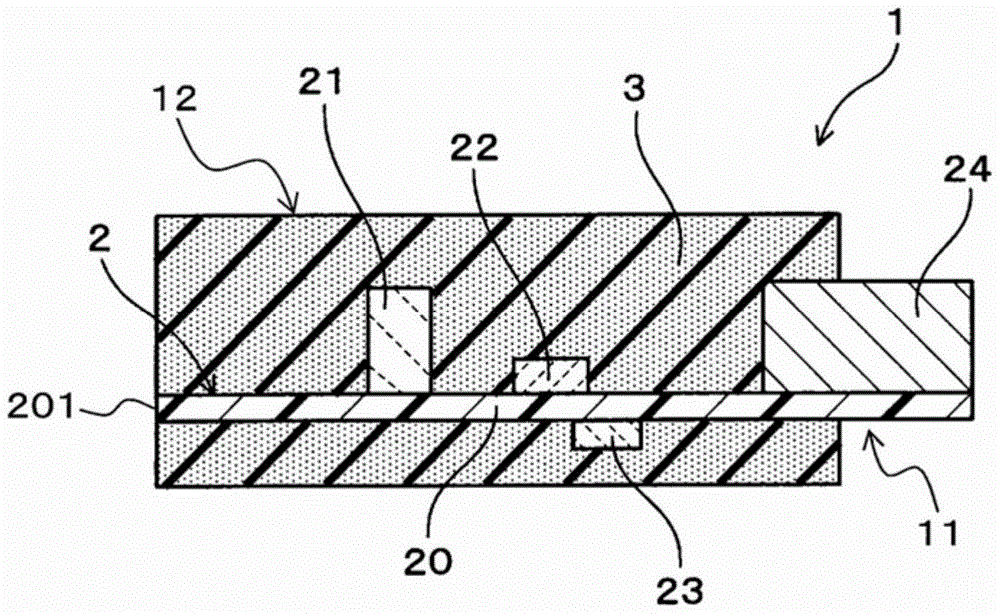

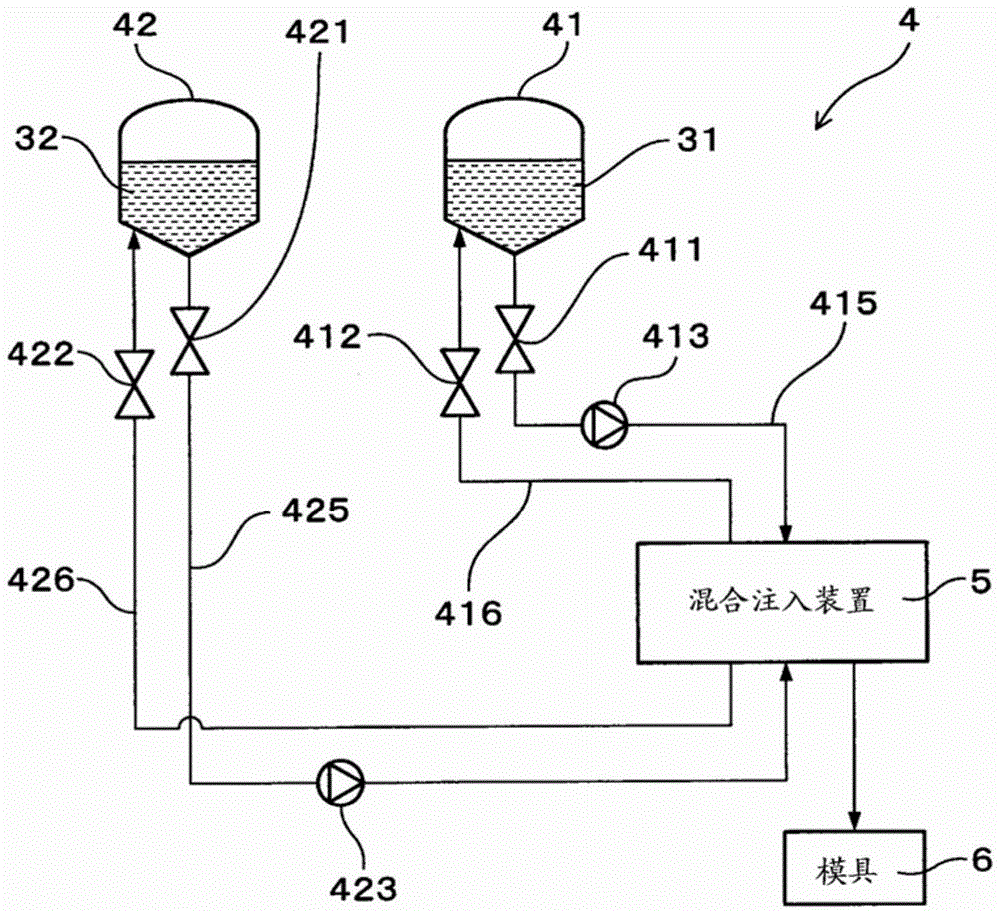

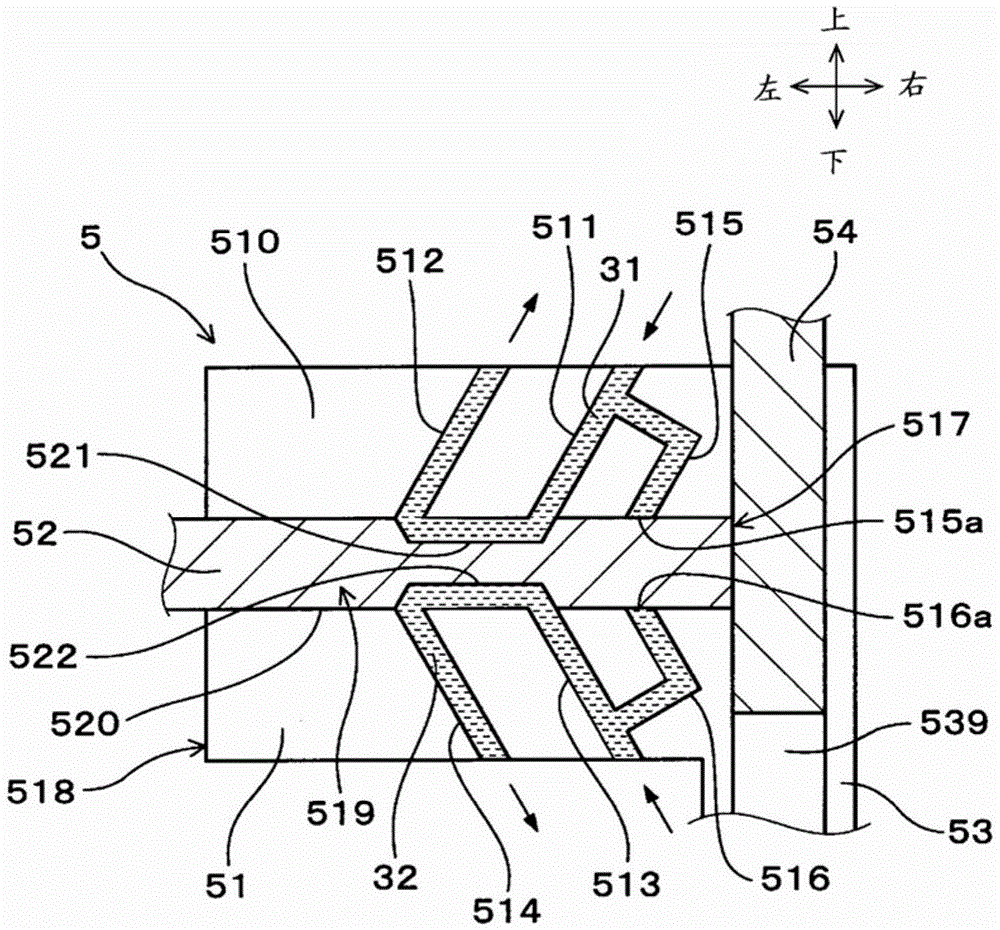

[0046] As follows, the electronic component unit and its manufacturing method will be described with reference to the drawings. Such as figure 1 As described, the electronic component unit 1 in this embodiment includes the electronic component 2 and the resin seal 3 coating the electronic component 2 . The resin seal 3 is made of foamed polyurethane resin. The electronic component unit 1 in this embodiment is an electronic control unit (ECU) for vehicles and has a printed wiring board 20 as the electronic component 2 . Electronic circuitry (not shown) is provided on the printed wiring board. The printed wiring board 20 (printed substrate 20) is a 60 mm long, 67 mm wide, and 1.6 mm thick board, and is made of a general glass epoxy substrate. On both sides of the printed wiring board 20 , various types of semiconductor elements 21 , 22 , 23 and connectors 24 corresponding to external connection terminals of the printed wiring board 20 are mounted. The semiconductor elements ...

no. 2 example

[0076] In this example, an electronic component unit was manufactured similarly to the first example except that the heating temperature of the first raw material liquid by the high-frequency induction heating coil was changed to 100°C. When the heating temperature was set to 100° C., the viscosity of the first raw material liquid was 71 mPa·s. In this example, similarly to the first example, evaluation of resin filling was performed. Furthermore, in this embodiment, similarly to the case of the first embodiment, a test piece made of a foamed resin molded body was produced under the same conditions as the resin seal, and the long-diameter dimension of the connecting hole, Durometer hardness, water penetration distance and breaking strength. In addition, the water penetration distance from the exposed portion of the electronic component unit was measured. The results are shown in Figure 21A to Figure 21C middle.

[0077] (third to sixth embodiments)

[0078] In the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com