Radiator for heating body and heating body with such a calandria radiator

A heat radiator and appliance technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve problems such as manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

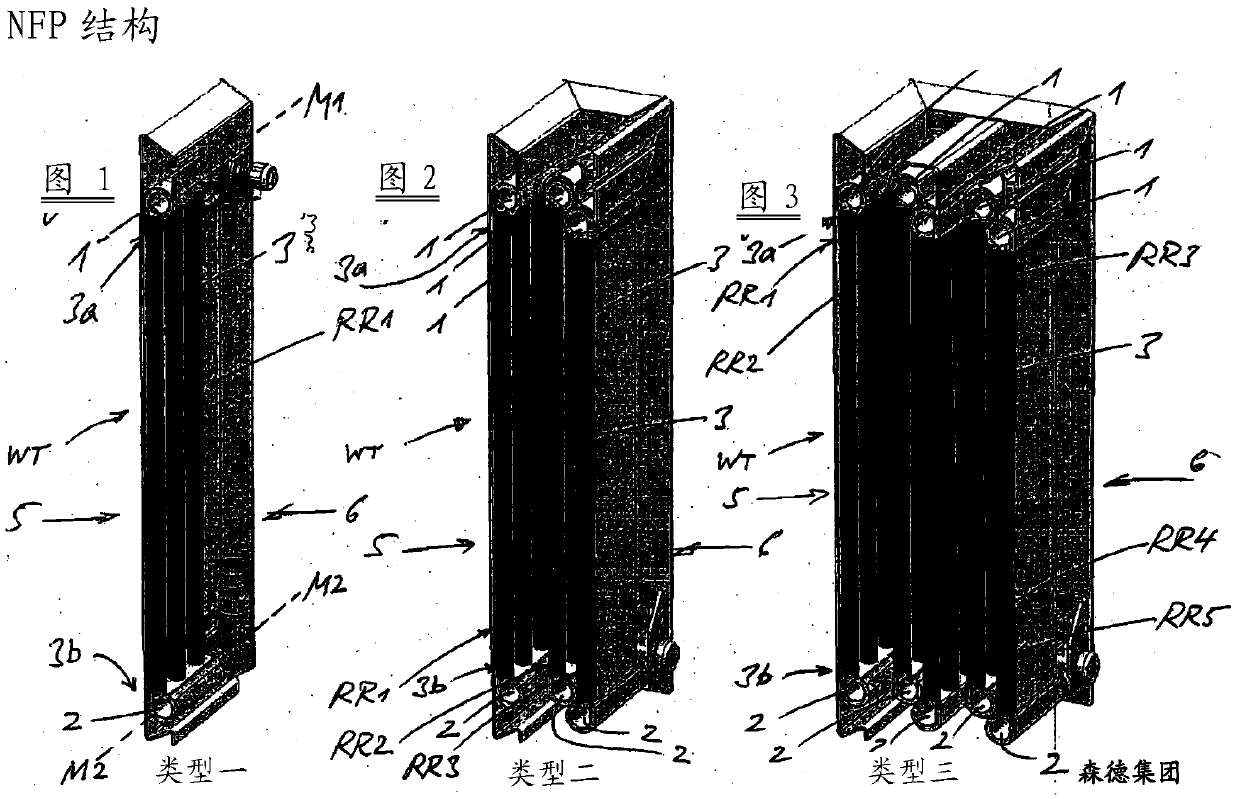

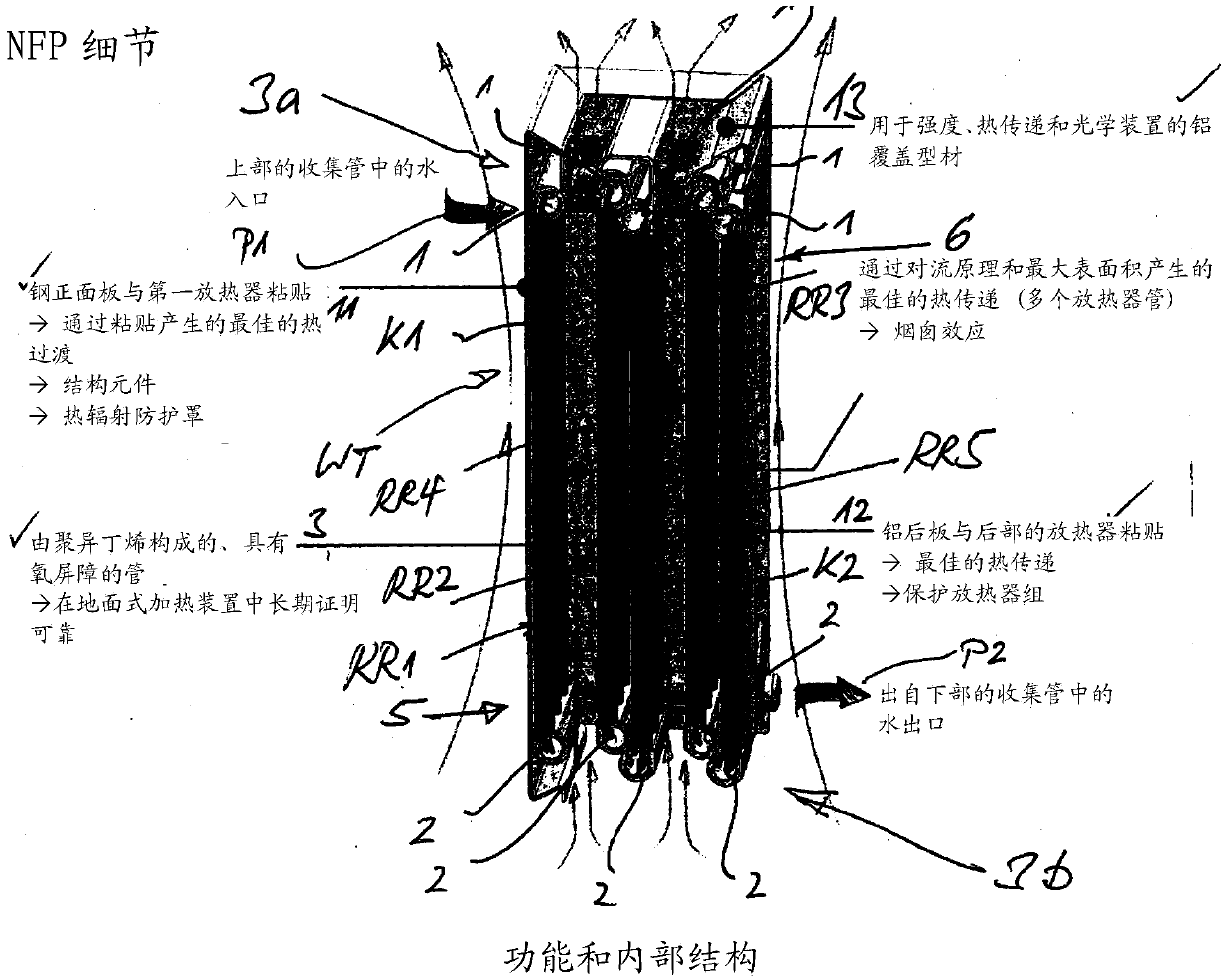

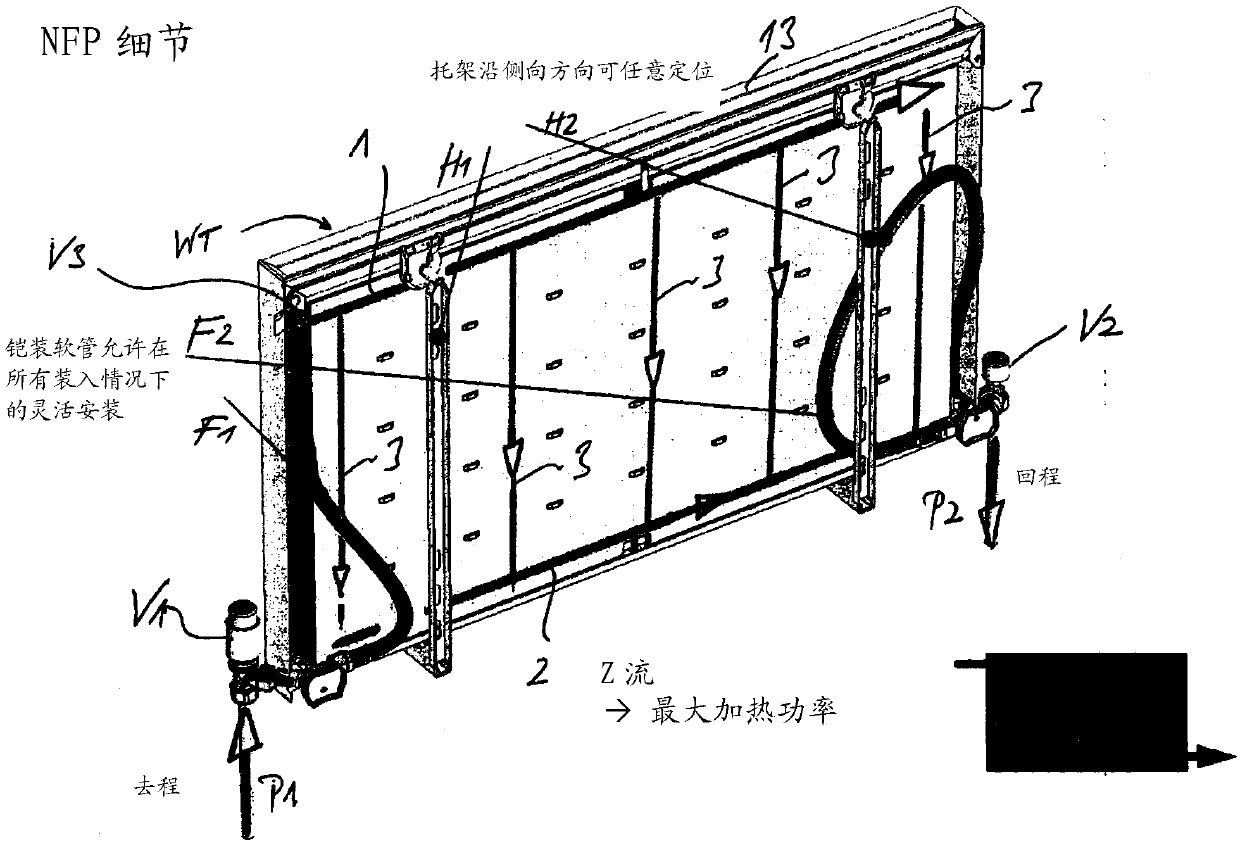

[0067] exist figure 1 A sectional view of a section of a first embodiment (type one) of a heating element WT according to the invention is shown, which comprises a single row radiator RR1 according to the invention. A go distributor 1 at the upper end of the calandria radiator RR1 and a return distributor 2 at the lower end of the calandria radiator RR1 are identified. A plurality of connecting pipes 3 extend between the forward distributor 1 and the return distributor 2 , said connecting pipes running parallel to one another. The row radiator RR1 forms a heat exchanger WT, in particular a heating or cooling body, through which a heat transfer fluid can flow. The connecting pipe 3 fluidly connects the outgoing distributor 1 with the return distributor 2 . The exhaust pipe radiator RR1 has a straight forward distributor 1 and a linear return distributor 2 extending parallel to it. A plurality of connecting pipes 3 extend between the forward distributor and the return distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com