hydrostatic axial piston machine

An axial piston machine, hydrostatic technology, applied in reciprocating piston engines, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problem of increasing weight and material consumption, hindering the preparation of casing vibration , can not provide the gap of the additional mass of acoustic measures, etc., to achieve the effect of light weight, reduce vibration tendency, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

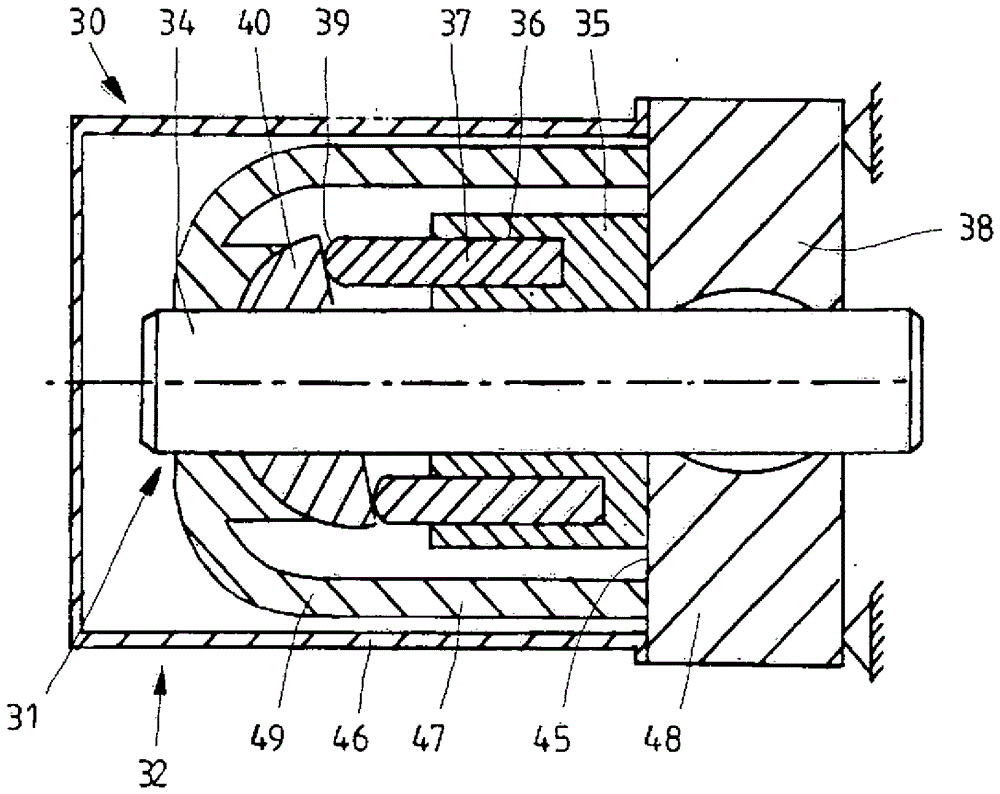

[0026] exist figure 1 The axial piston machine 1 shown in , which is designed as a swash plate, has a drive 2 which is arranged in a housing 3 . As main components, the drive mechanism 2 comprises a drive shaft 4 rotatably mounted via two roller bearings 8, 9, a cylinder drum 5, a housing-fixed connecting plate 10 coaxially passed through by the drive shaft 4, said cylinder drum having An axially extending cylinder bore 6 arranged on a partial circle with a longitudinally displaceable piston 7 in said cylinder bore is non-rotatably and axially displaceably connected to the drive via a synchronizing area 11 in the form of a cylinder tooth. Axis 4 is connected.

[0027] The piston 7 , which is guided longitudinally displaceably in the cylinder bore 6 , has a cylindrical configuration. The ends of the pistons 7 facing away from the cylinder drum are each supported on a swash plate 13 via hinges 12 .

[0028] The drive shaft 4 passes through the swash plate 13 . What is not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com