A machete device for a numerically controlled machete machine

A machete and machete technology, which is applied in the field of machetes, can solve the problem that machetes are difficult to bend thick blades and large angles, and achieve the effect of reducing the bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

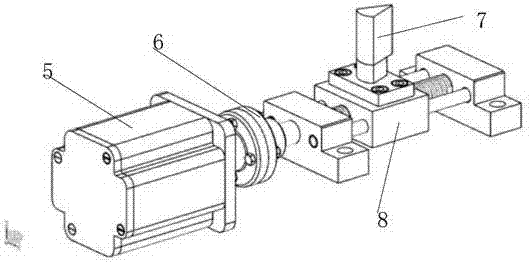

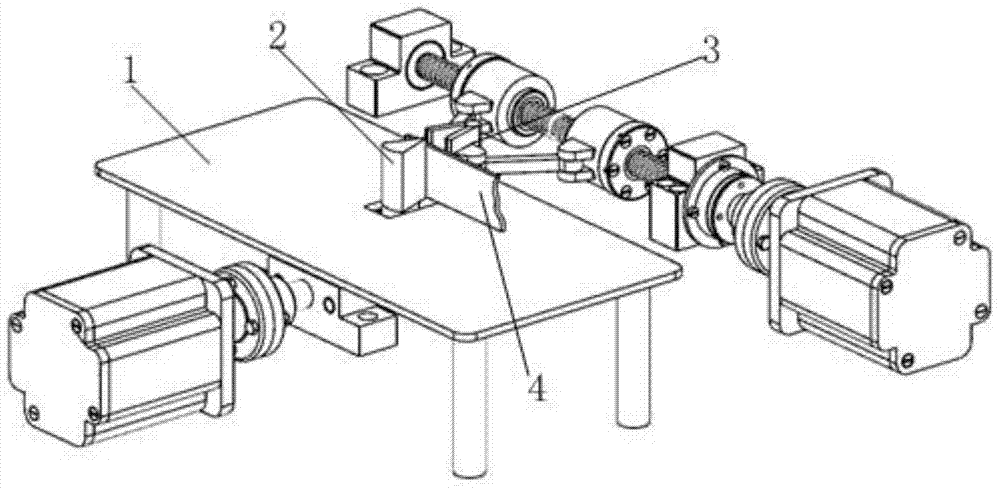

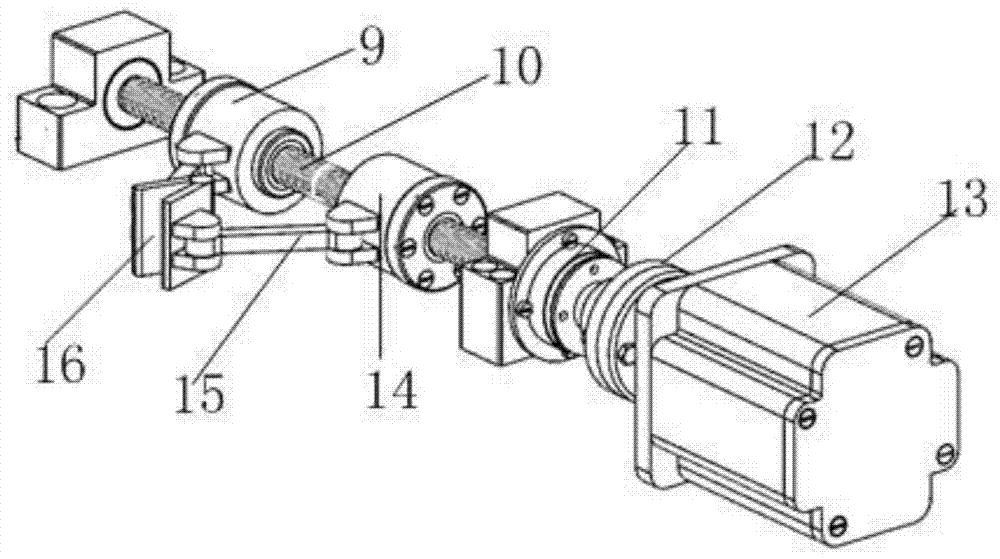

[0016] combine Figure 1 to Figure 3 , the CNC machete machine of the present invention uses a machete device as a whole consisting of a work surface 1, a moving knife block mechanism 2 for feed motion, a fixed knife block mechanism 3 with variable angles, and a blade 4 as a work object. The shape of the blade to be bent is determined by the computer to determine the V-shaped angle size of the fixed knife block 15 and the feed rate of the movable knife block 7, and then convert the required rotation angles of the motors 5 and 13. The motor 13 drives the positive and negative lead screw 10 to rotate through the shaft coupling 12. When the lead screw 10 rotates, it drives the two lead screw nuts 9 and 14 to move toward each other, and controls the angle change of the fixed knife block 16 through the connecting rod 15, and 16 and 7 The angle bisector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com