A whole row of contact body bending device

A technology of bending device and contact body, applied in the direction of contact parts manufacturing, etc., can solve the problems of difficult quality assurance, poor bending consistency, uneven height, etc., to improve quality consistency and production efficiency, and the process is simple and easy to implement , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

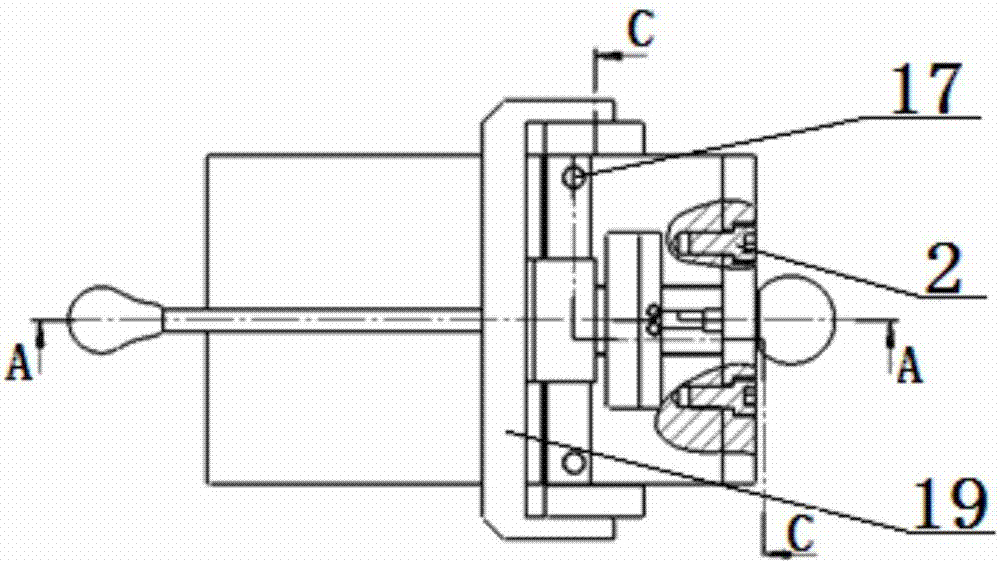

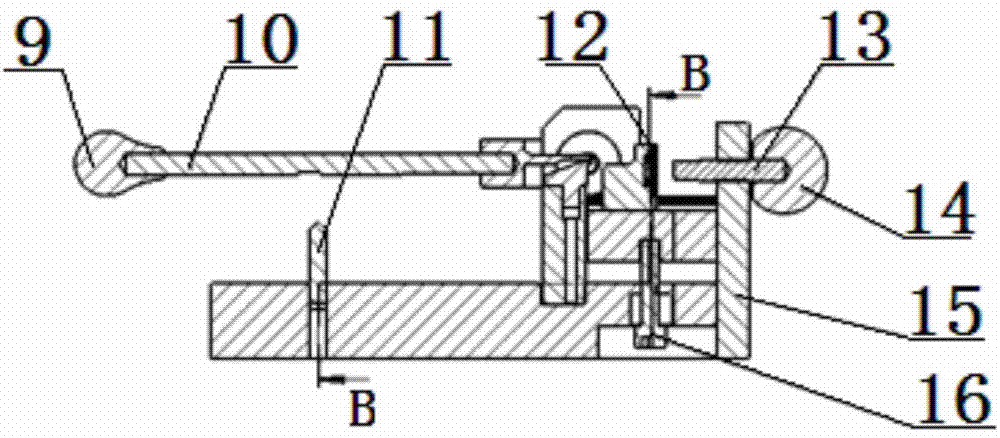

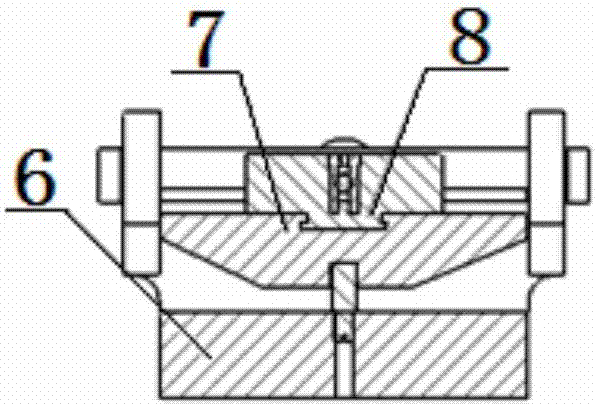

[0034] The whole row of contact body bending device is composed as follows: positioning plate 1, left vertical plate 3, bearing 4, shaft 5, base 6, support plate 7, clamping plate 8, positioning bolt 11, pin 12, clamping rod 13. Handle II 14, right vertical plate 15, adjustment bolt 16 and looper plate 19; the right vertical plate 15 is fixedly connected to one end of the base 6, and the other end of the base 6 is connected with a positioning bolt 11; the adjustment bolt 16 is worn through The base 6 is connected to the support plate 7, and the height of the support plate is adjusted by adjusting the bolt 16 to realize the up and down positioning adjustment of the parts; the clamping plate 8 is slidably connected to the support plate 7 through a T-shaped groove, and one end of the clamping rod 13 is threaded After passing through the right vertical plate 15, it is connected with the handle II 14 to realize parts clamping; the other end of the clamping rod 13 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com