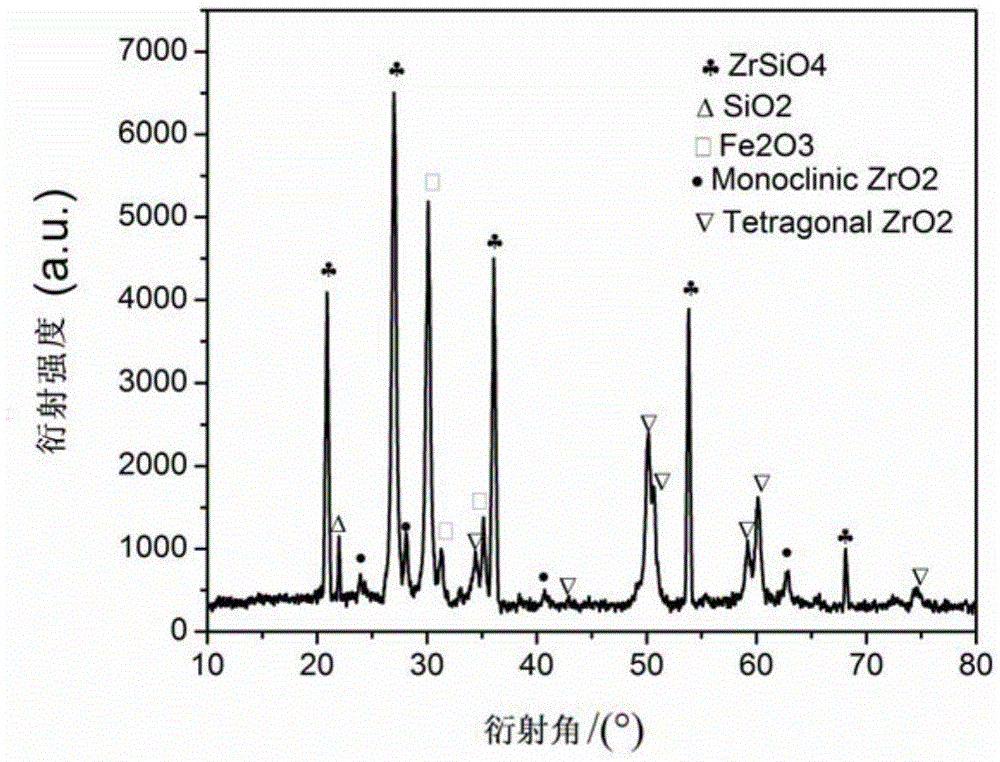

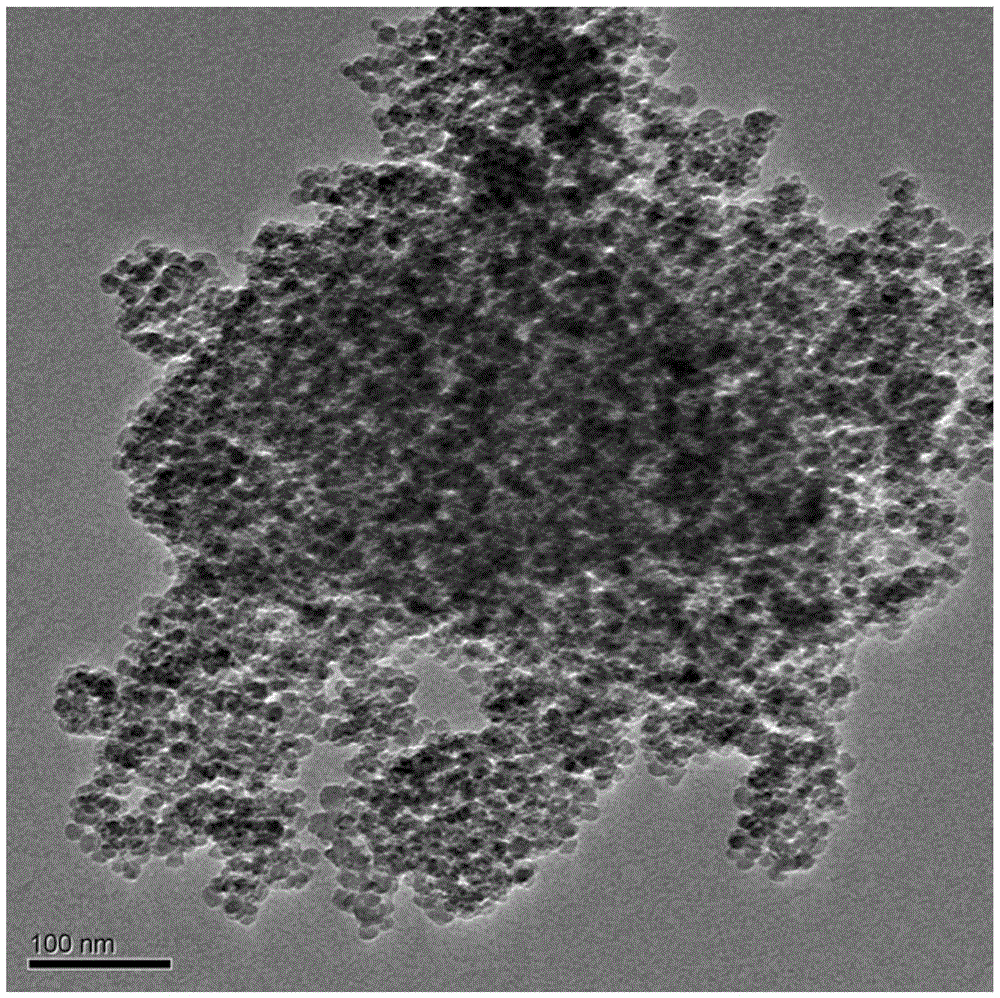

A method for preparing zirconium-based wrapped zirconium-iron red ceramic pigment by organic network method

A technology of ceramic pigment and organic network, which is applied in the field of preparation of inorganic ceramic powder and ceramic materials, to achieve the effects of high efficiency, good packaging of pigment, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of organic network precursor:

[0036] According to the concentration of polyvinyl alcohol of 4%, polyvinyl alcohol and water are mixed, heated and stirred at about 80° C. for 2-3 hours, and then allowed to stand and cooled to room temperature to obtain an aqueous solution of polyvinyl alcohol.

[0037] 2.Zr 4+ Preparation of other inorganic / organic network gels:

[0038] Take 70ml of the above-prepared polyvinyl alcohol solution, add 30g of zirconium oxychloride according to the ratio and stir until it is completely dissolved; then add 5.02g of ferric nitrate nonahydrate and stir until dissolved; add 22.37g of silica sol, 1g of dispersant PEG400 and stir evenly ;Finally, add 10ml of glutaraldehyde and stir quickly until a gel is formed;

[0039] 3. Zr 4+ Other inorganic / organic network gel post-treatment:

[0040] After the above gel was left to stand for 3 hours, it was soaked in 25% ammonia water for 24 hours, washed with deionized water until neutra...

Embodiment 2

[0045] 1. Preparation of organic network precursor:

[0046] According to the concentration of polyvinyl alcohol of 4%, polyvinyl alcohol and water are mixed, heated and stirred at about 85° C. for 2-3 hours, and then allowed to stand and cooled to room temperature to obtain an aqueous solution of polyvinyl alcohol.

[0047] 2.Zr 4+ Preparation of other inorganic / organic network gels:

[0048] Take 60ml of the above-prepared polyvinyl alcohol solution, add 40g of zirconium oxychloride according to the proportion and stir until it is completely dissolved; then add 8.04g of ferric nitrate nonahydrate and stir until dissolved; then add 29.83g of silica sol, 1.5g of dispersant PEG400 Stir well; finally add 8ml of glutaraldehyde, stir quickly until a gel is formed;

[0049] 3. Zr 4+ Other inorganic / organic network gel post-treatment:

[0050] After the above gel was left to stand for 3 hours, it was soaked in ammonia water (mass percentage concentration 25%) for 24 hours, washe...

Embodiment 3

[0054] 1. Preparation of organic network precursor:

[0055] According to the polyvinyl alcohol concentration of 6%, the polyvinyl alcohol and water were mixed and heated and stirred at about 85° C. for 2-3 hours, and then stood to cool to room temperature.

[0056] 2.Zr 4+ Preparation of other inorganic / organic network gels:

[0057] Take 70ml of the above-prepared polyvinyl alcohol solution, add 30g of zirconium oxychloride according to the proportion and stir until it is completely dissolved; then add 7.52g of ferric nitrate nonahydrate and stir until dissolved; then add 22.37g of silica sol and 1g of PEG400 and stir evenly; Finally, add 10ml of glutaraldehyde and stir quickly until a gel is formed;

[0058] 3. Zr 4+ Other inorganic / organic network gel post-treatment:

[0059] After the above gel was left to stand for 3 hours, it was dried in an oven at 90°C and crushed into fine powder;

[0060] 4. Preparation of zirconium iron red ceramic pigment:

[0061] Calcining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com