Halogenated rubber composition, preparation method and application

A kind of halogenated rubber, the technology of composition, is used in the preparation of above-mentioned halogenated rubber blend, the field of halogenated rubber blend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

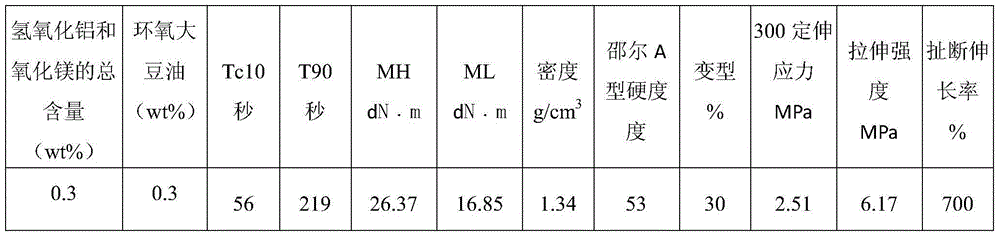

[0038] Ingredient-Property Relationships of Halobutyl Compositions

[0039] In this experiment, after dissolving butyl rubber (isobutylene-p-methylstyrene copolymer can also be used) to form a concentration of 15 wt% hexane solution 400g, then add 2.4g liquid bromine to react, and then add a small amount of hydrogen to Neutralize with aqueous sodium solution and wash with distilled water to pH 7-8. Different amounts of magnesium hydroxide and aluminum hydroxide (Mg / Al molar ratio of 3:1) and epoxidized soybean oil were uniformly dispersed in hexane to form a dispersion liquid, then added and stirred for 5 minutes. Then use steam to remove hexane, and then use an open mill to squeeze and dehydrate to obtain a brominated butyl rubber composition dried to a volatile content of less than 0.5 wt%. Then the composition is mixed with the commercially available Exxon2222 as a comparison rubber using the following formula, and then tested at 180°C using a vulcanization tester accordin...

Embodiment 2

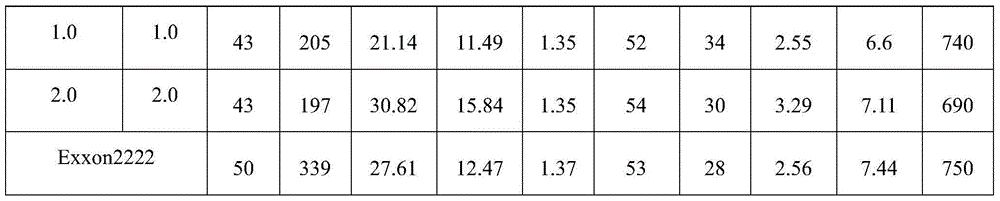

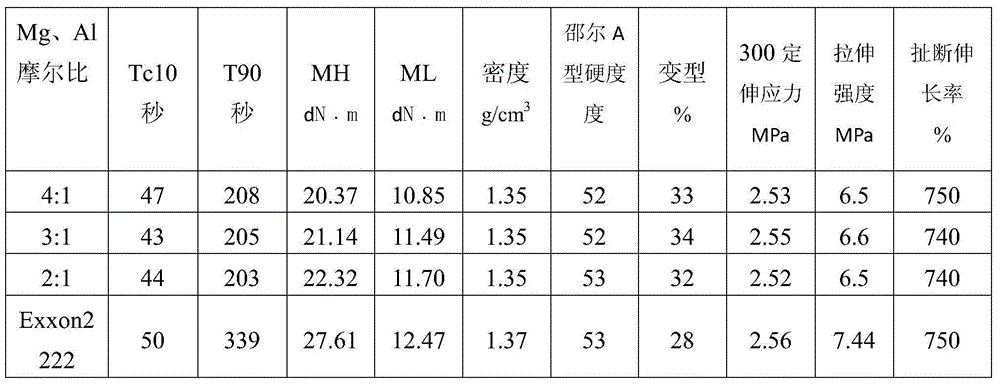

[0046] This example describes the difference in performance of the composition under different ratios of Mg and Al, wherein the weight fraction of the components containing Mg and Al is 1 wt% of the halogenated rubber composition, and the amount of epoxy soybean oil added is 1 wt% of the halogenated rubber composition. 1 wt%.

[0047] According to the steps in Example 1, the halogenated butyl rubber compositions containing different Mg / Al molar ratios were synthesized by adjusting the weight of additives added to the brominated rubber solution after washing. The comparison rubber is commercially available Exxon2222. The mixing formula and test method are the same as in Example 1. The results are shown in Table 2.

[0048] Table 2 The relationship between different contents of Mg, Al and epoxidized soybean oil and the properties of the composition

[0049]

[0050] It can be seen from Table 2 that under different molar ratios of Mg and Al, there is little difference in pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com