Anti-leakage anti-overpressure mixed water thermostatic valve

An anti-overpressure and anti-leakage technology, applied in the direction of multi-way valves, control valves, safety valves, etc., can solve the problems of electric shock, high manufacturing cost, etc., and achieve the effect of good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

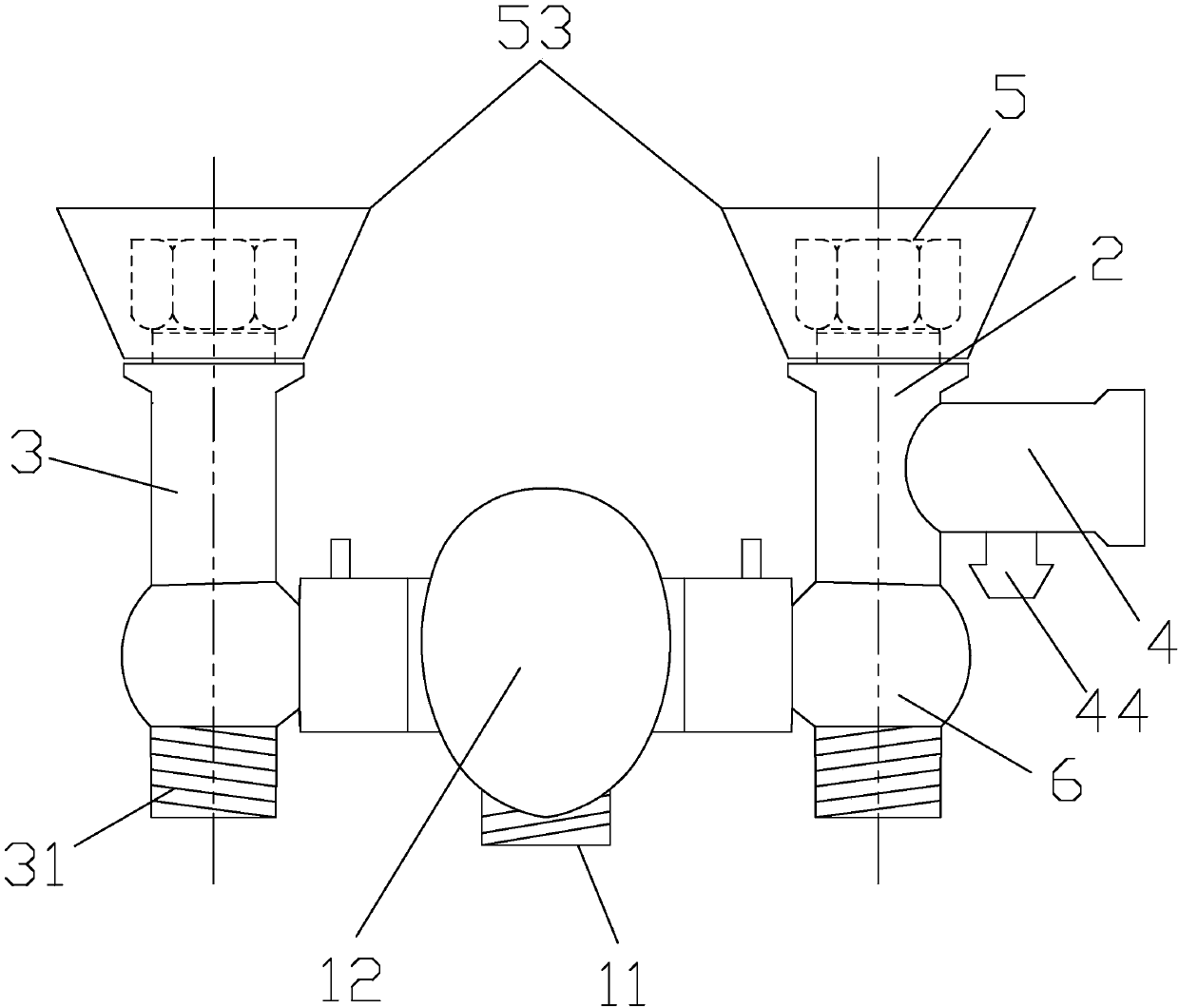

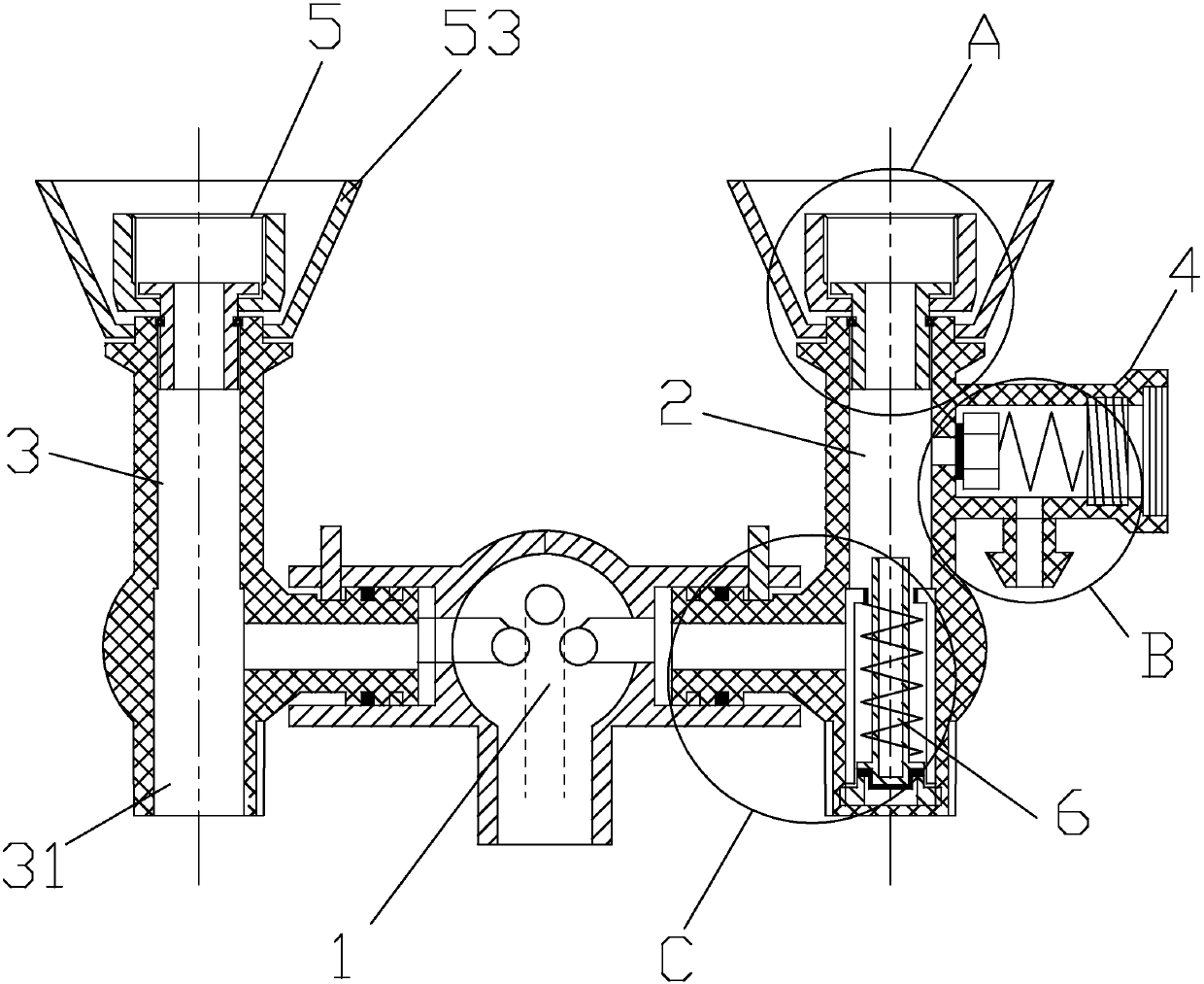

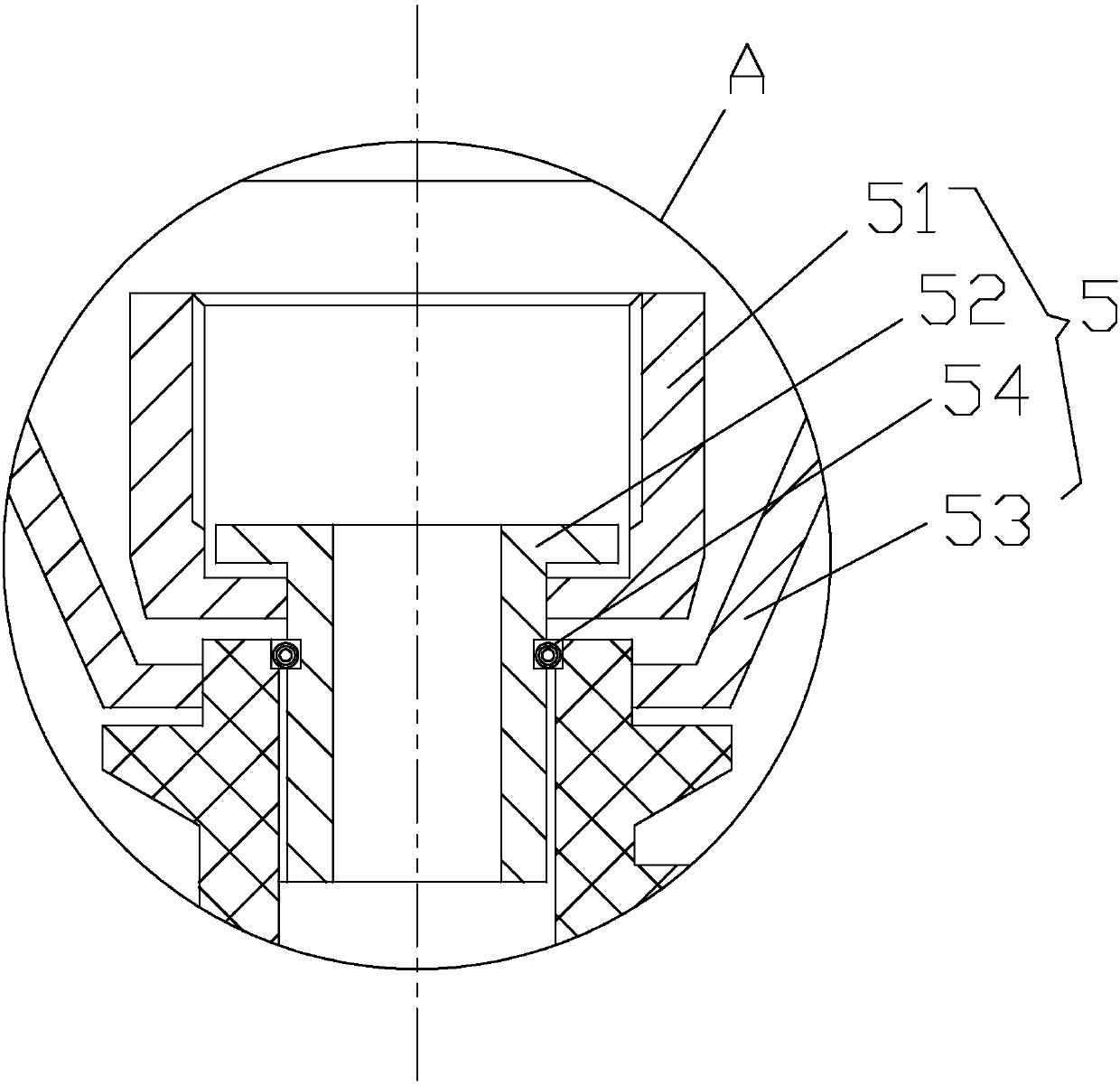

[0022] refer to Figure 1 to Figure 5 , an anti-leakage anti-overpressure anti-overpressure water mixing thermostatic valve provided in this embodiment includes a water mixing valve 1 and an external pressure relief valve 4. The water mixing valve 1 is connected with a cold water channel 2 and a hot water channel 3. The water inlet of the cold water channel 2 communicates with the tap water pipe through the check valve 6, and the lower part of the hot water channel 3 is provided with a hot water pipe outlet joint 31, and the cold water channel 2 and the hot water channel 3 are made of non-metallic materials , the upper end of the cold water channel 2 and the upper end of the hot water channel 3 are respectively provided with a connecting piece 5 connected with the water inlet of the electric hot water tank and connected with the water outlet of the electric hot water tank. The outer hex nut 51, the T-shaped connector 52 connected to the outer hex nut 51 and the cold water chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com