Measuring mechanism

A technology of measuring mechanism and measuring arm, applied in the directions of measuring devices, measuring instrument components, instruments, etc., can solve the problems of operator fatigue, increased weight of measuring mechanism, affecting measurement accuracy, etc., to facilitate manual operation, enhance stability, guarantee The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

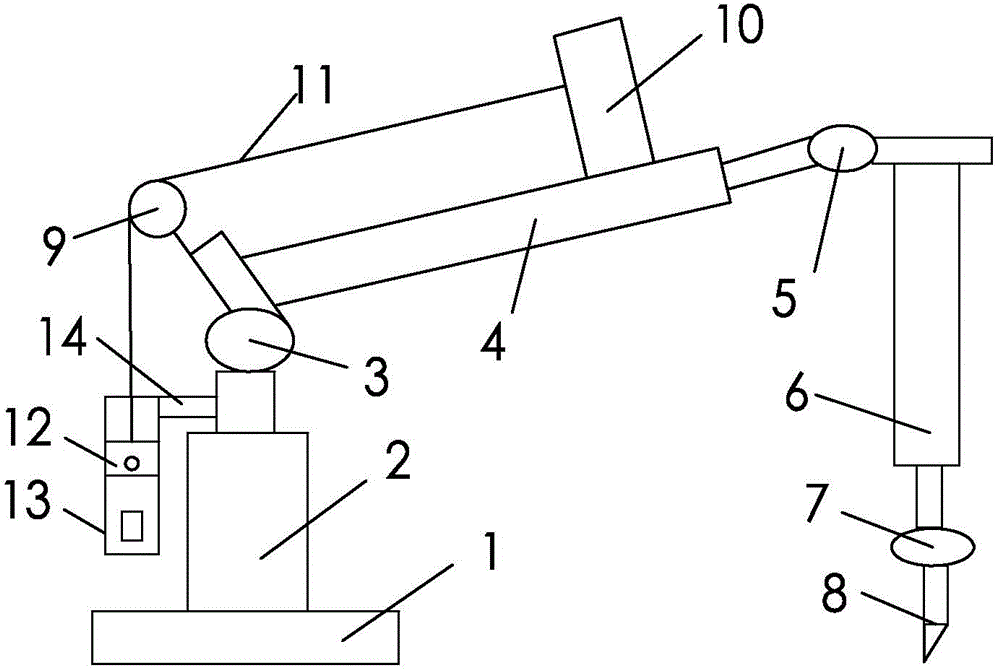

[0014] Such as figure 2 As shown, a measuring mechanism includes a base 1 and a base body 2 above it. The base body 2 is sequentially connected with a joint one 3, a measuring arm one 4, a joint two 5, a measuring arm two 6, a joint three 7 and a measuring arm. Head 8, a pulley 9 is provided above the end connected to the joint one 3 of the measuring arm one 4, and a connecting block 10 is provided above the end connected to the joint two 5; a steel band 11 is also included, and one end of the steel band 11 The connecting block 10 is connected, and the other end is connected with a weight 12 after passing through the pulley 9 .

[0015] The weight 12 is placed in a buffer 13 as a whole, and the buffer 13 is connected to the upper end of the base 2 through a cross bar 14 .

[0016] The present invention bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com