A method of combined directional x-ray transillumination for materials with different thicknesses

An X-ray and combination technology, applied in the field of non-destructive testing, can solve problems such as failure to meet the normal production progress requirements of products, low utilization rate of X-ray field dose, failure to effectively use available rays, etc. Radiation dose absorption and labor intensity, the effect of solving detection progress problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

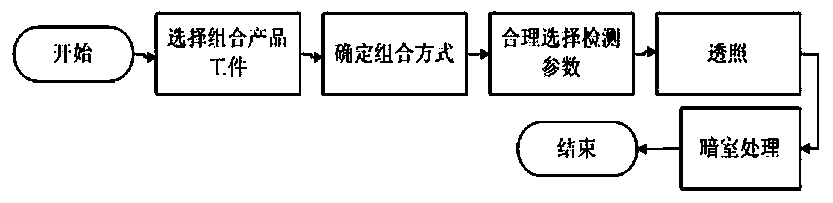

[0040] A method for combined directional X-ray transillumination of materials with different thicknesses, specifically comprising the following steps:

[0041] a. Select the combined product workpiece, and select the welded and polished 6, 8, 10mm welding test plates with similar shape, size and structure for combination;

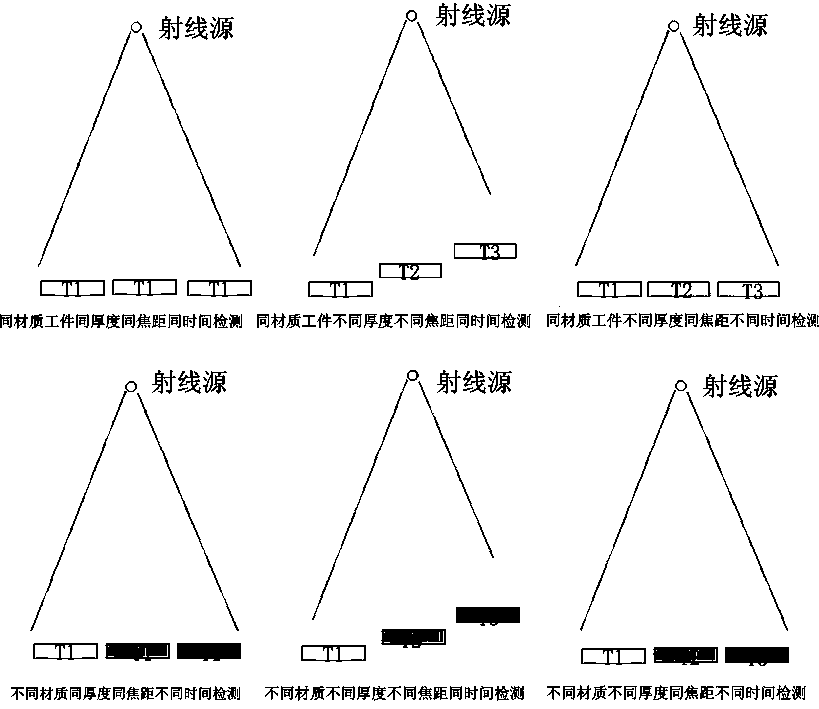

[0042] b. Determine the combination method, and the following combinations can be carried out for the selected workpiece: same focal length and same time detection, different focal length and different time detection, same focal length and different time detection;

[0043] c. Determine the transillumination parameters, the specific transillumination parameters are shown in Table 5 below.

[0044] Table 5 Transillumination parameters

[0045]

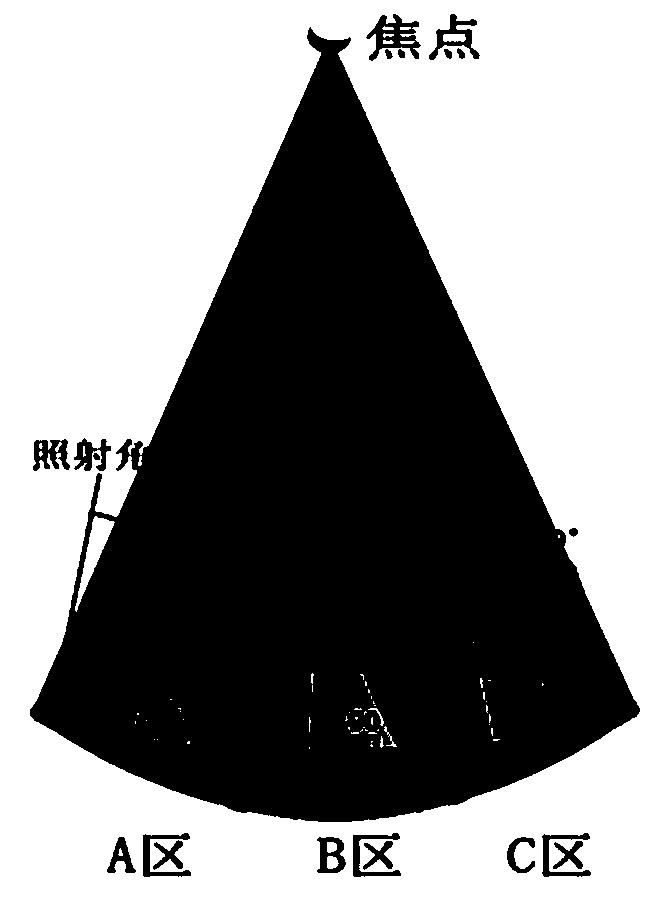

[0046] d. Carry out transillumination, after selecting the transillumination parameters, conduct directional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com