Roll manufacturing method and manufacturing device

A technology of vibration suppression and winding into rolls, which is applied in the field of manufacturing rolls, can solve the problems of weak force and difficulty in the non-contact state, achieve the effect of preventing the possibility of defects and improving the quality of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

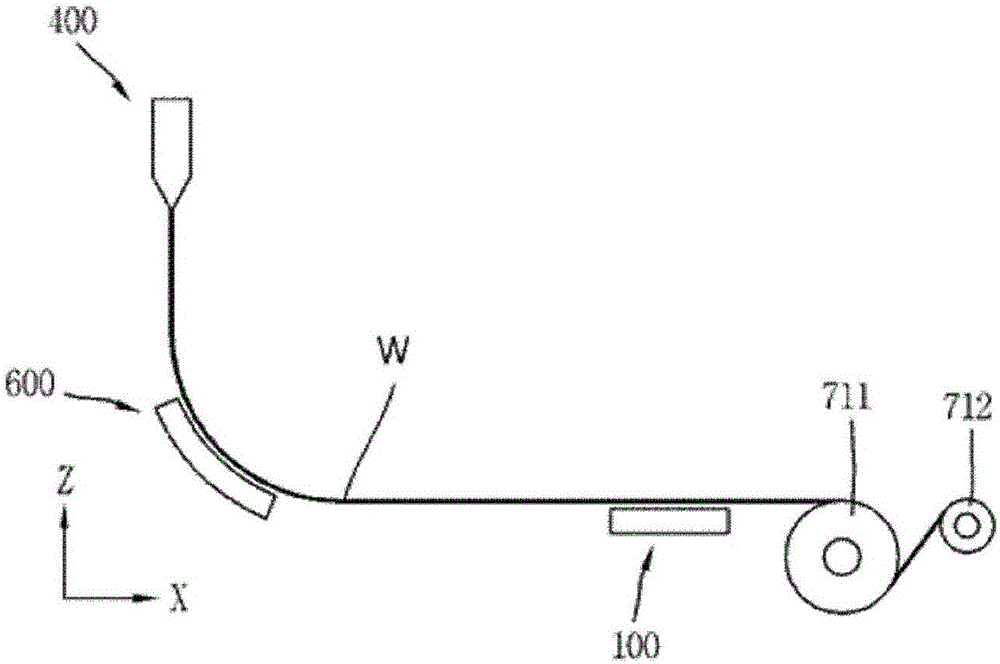

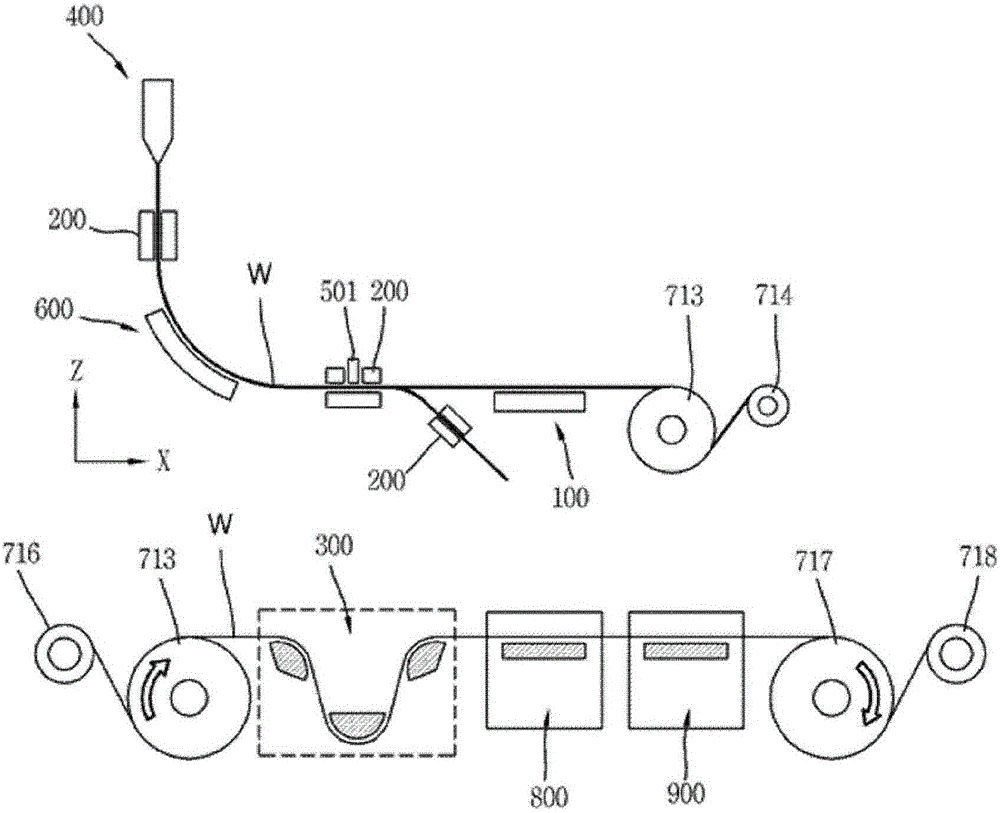

[0027] figure 1 is a schematic side view showing a first exemplary embodiment of the apparatus for manufacturing rolls according to the present invention.

[0028] figure 1 The apparatus for manufacturing rolls shown in includes a forming unit 400, a transport unit 100, a redirection unit 600 and a winding unit.

[0029] The forming unit 400 forms the raw material into a glass web (glass web, or “glass soft plate”) W. The redirection unit 600 changes the direction in which the glass web W is transported. exist figure 1 On the paper of , the redirection unit 600 changes the transport direction from a vertical downward direction to a horizontal direction. Specifically, the glass web W formed in the forming operation is conveyed vertically downwards to a redirection unit 600 disposed on the path along which the glass web W is conveyed. The tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com