Novel color changing valve structure and work method thereof

A new type of paint technology, applied in the field of color change valves, can solve the problems of increasing solvent consumption and achieve the effect of reducing color change time and saving solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

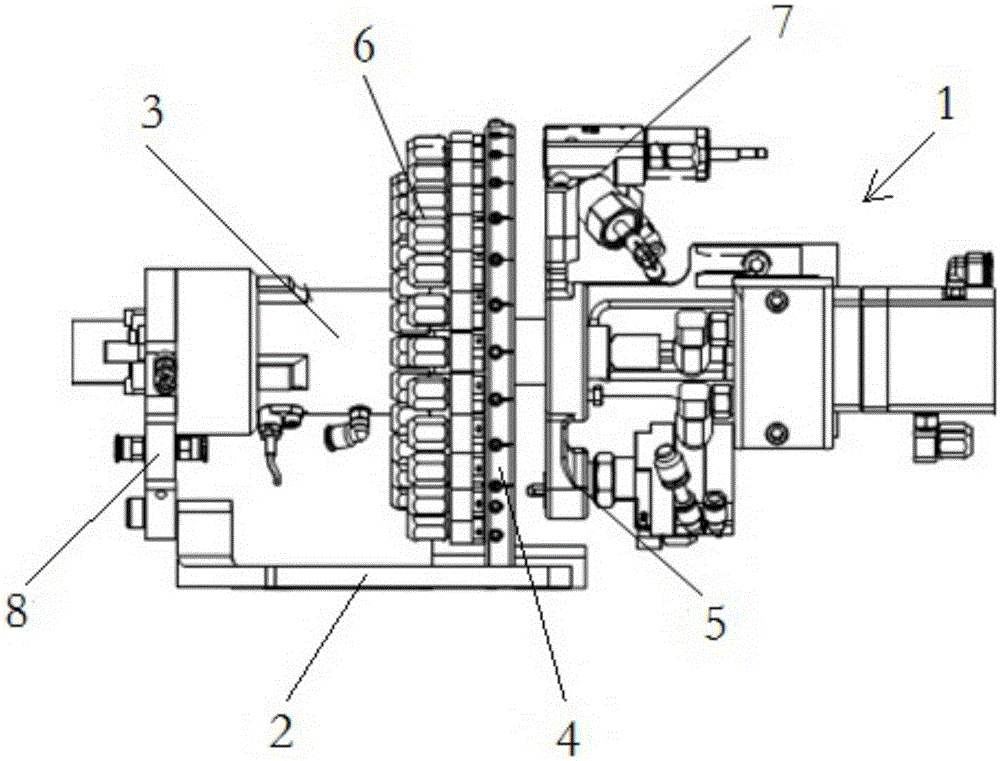

[0020] See figure 1 As shown, the structure of a novel color-changing valve 1 of the present invention includes a base 2, a main shaft 3, a wheel 4 and a turntable 5, wherein the main shaft 3 is horizontally arranged above the base 2 and runs through the wheel 4, and the turntable 4 is rotatable The ground is connected with the main shaft 3, the wheel disc 4 has a number of paint input ports 6, and the turntable 5 has a paint output port 7, the paint input port 6 and the paint output port 7 can be docked to realize the replacement of spray paint and paint color.

[0021] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to figure 1 as shown,

[0022] In a further embodiment of the present invention, several paint input ports 6 are uniformly arranged on the edge of the wheel 4 .

[0023] In a further embodiment of the present invention, the paint output port 7 is arranged on the edge of the turntable 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com