Patents

Literature

30results about How to "Reduced solvent consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feedback mechanism for smart nozzles and nebulizers

ActiveUS20070299561A1Reduce the amount requiredImprove performanceSelf-acting watering devicesWatering devicesFluorescenceLaser light

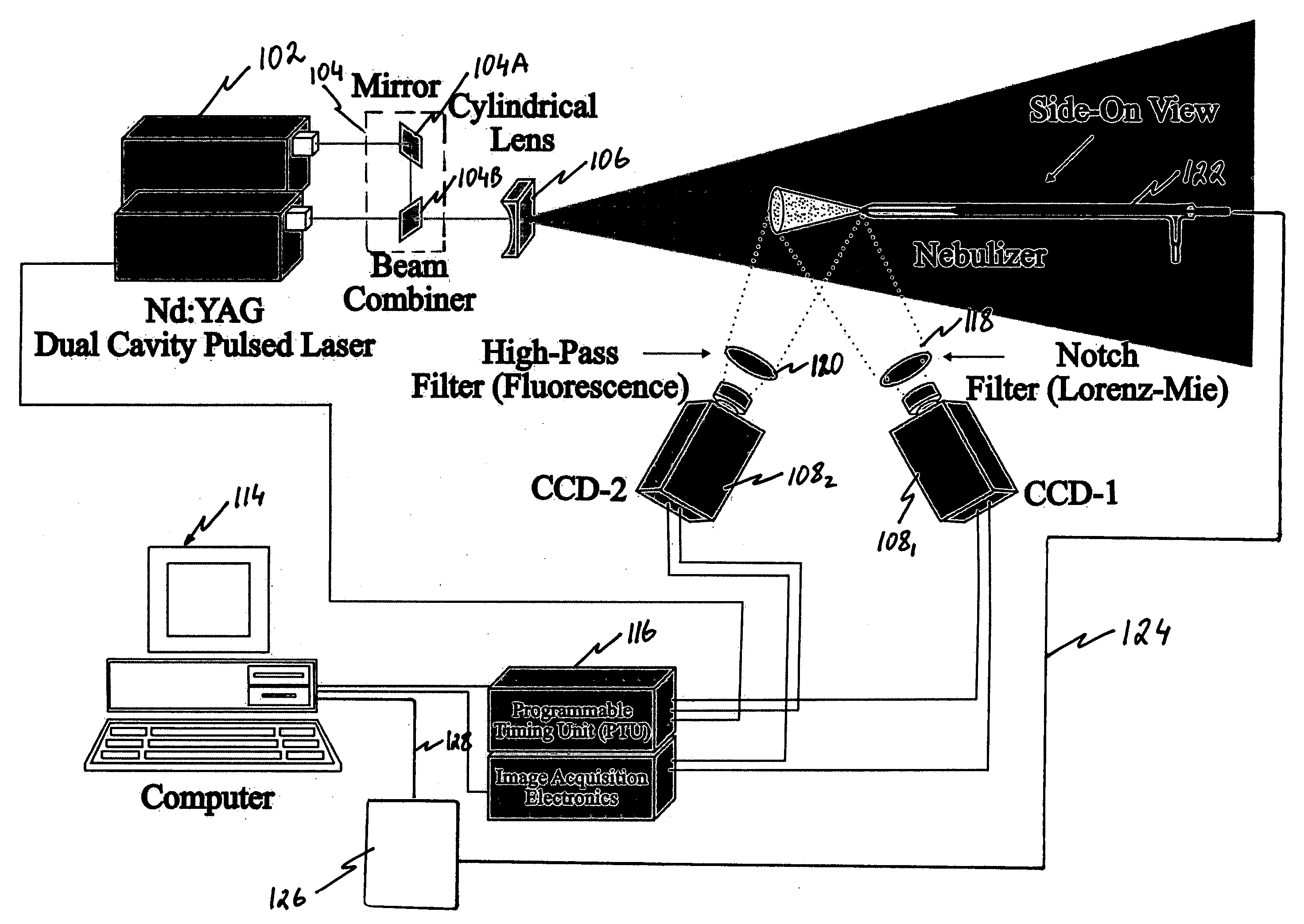

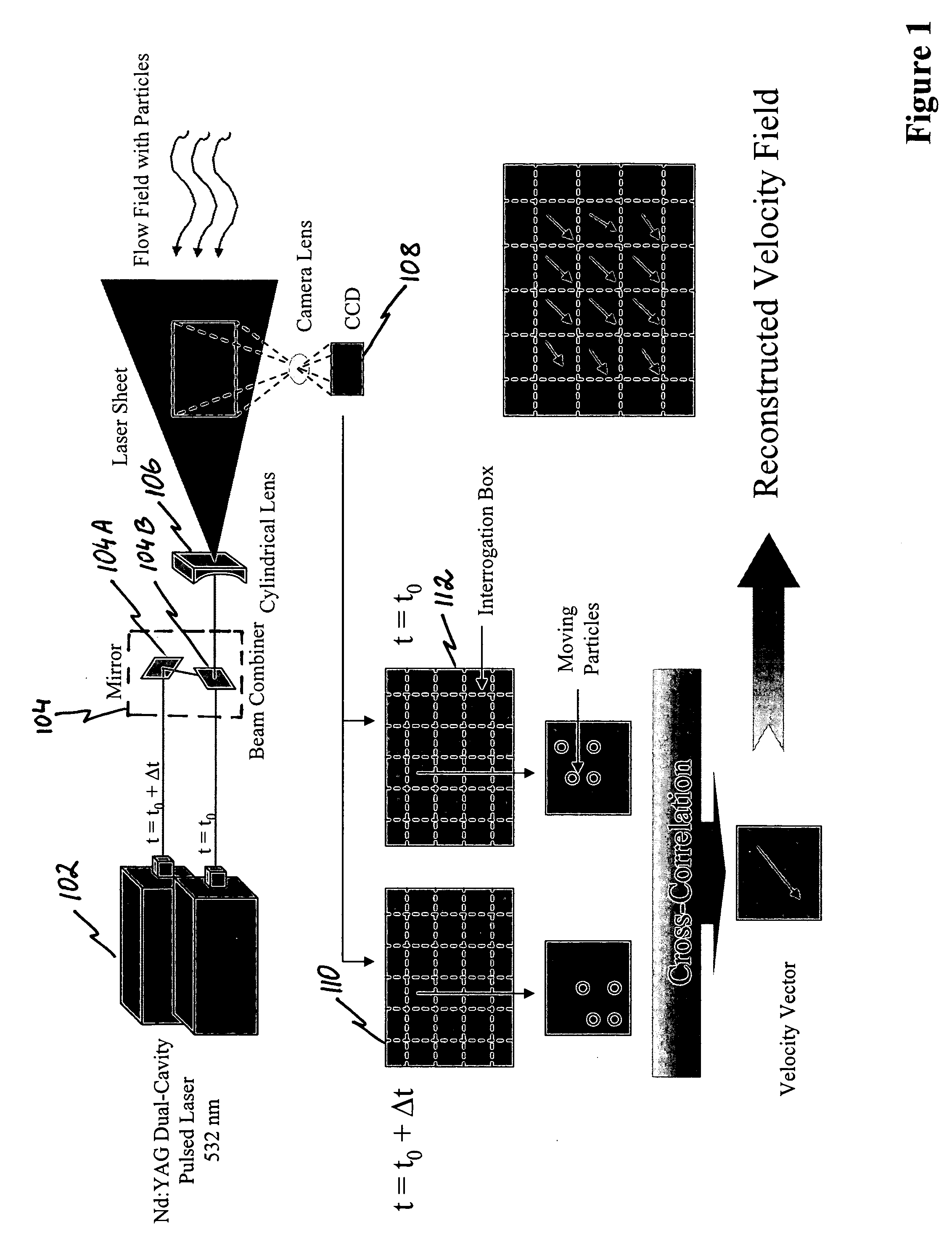

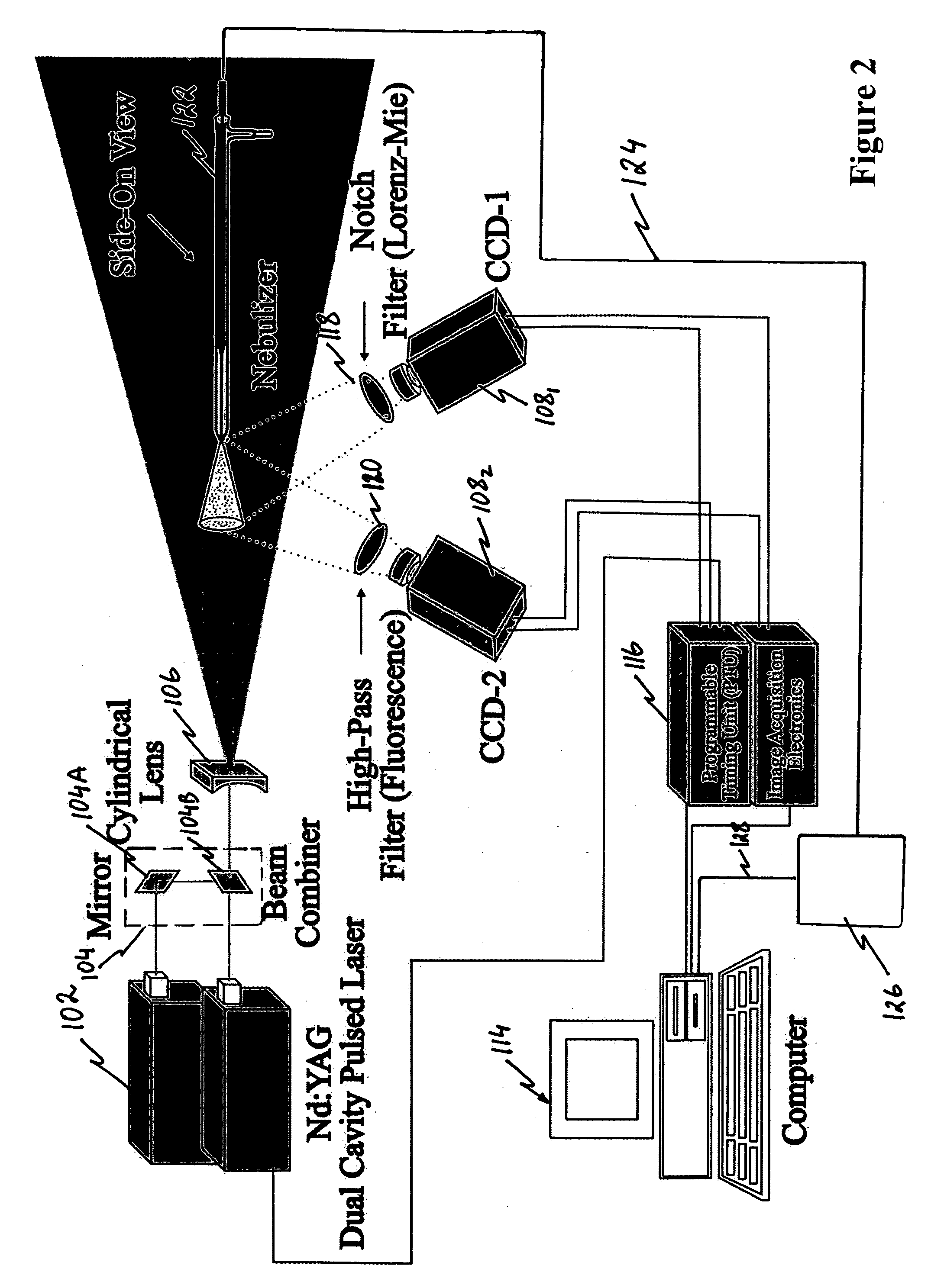

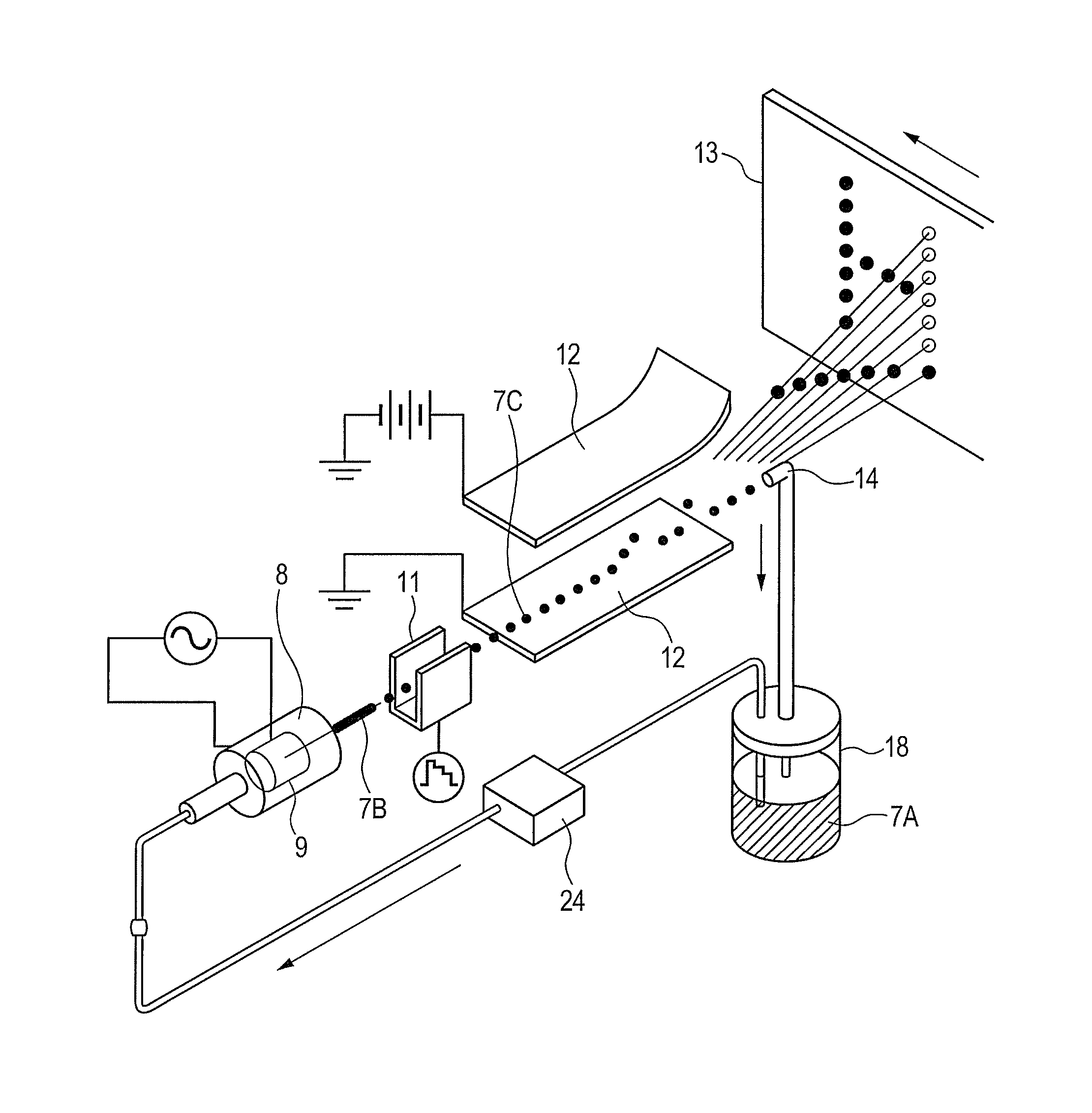

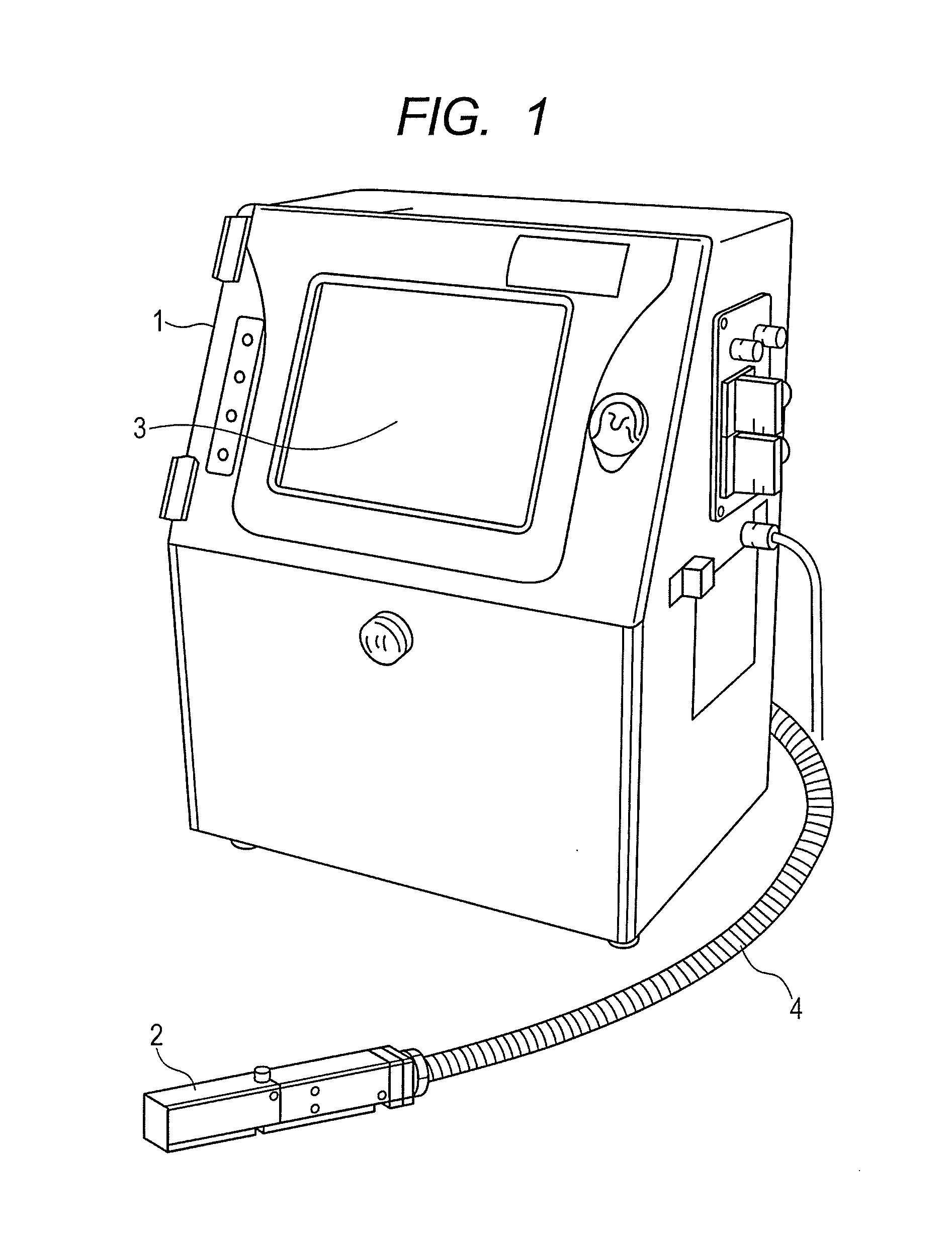

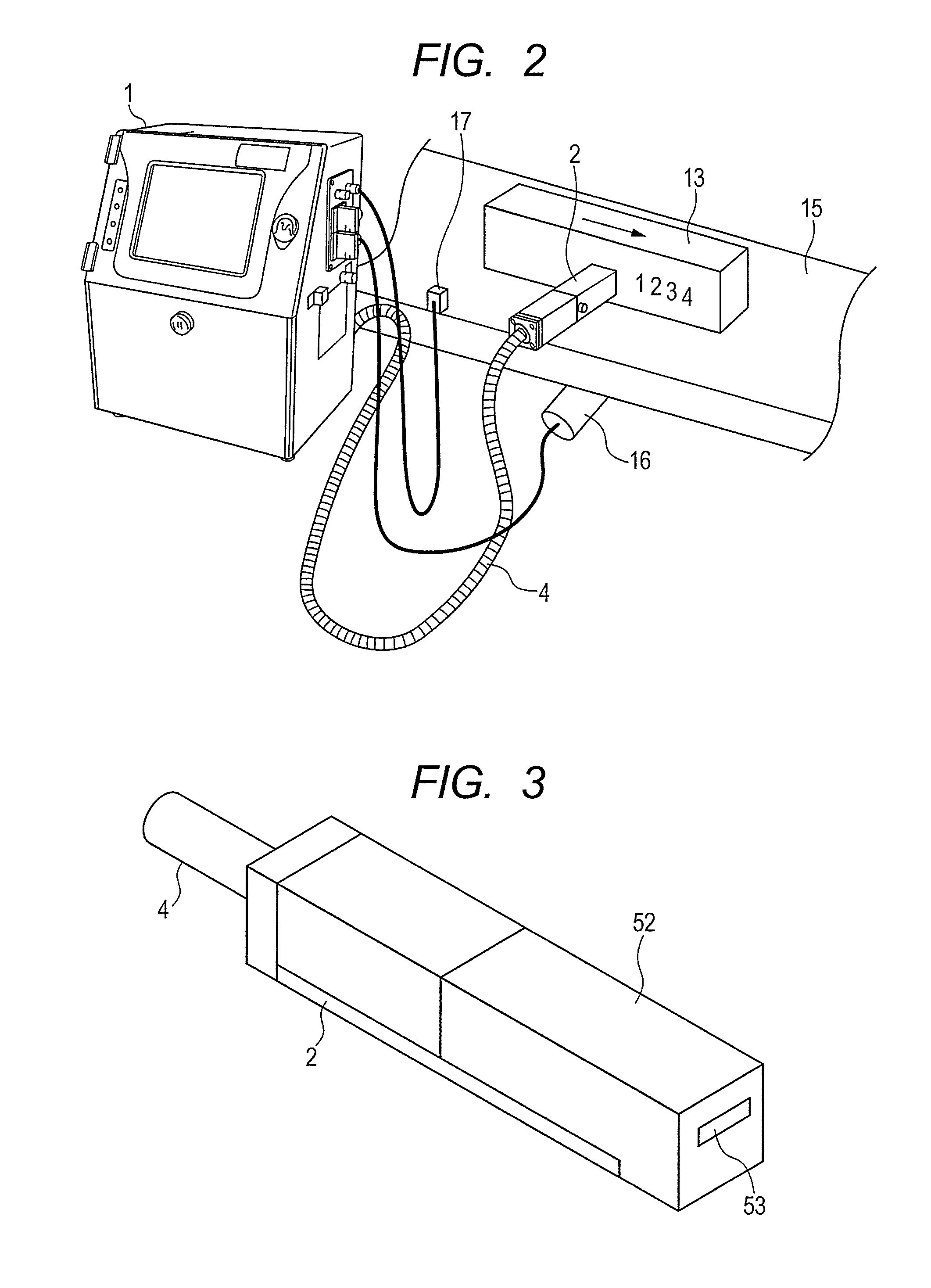

Nozzles and nebulizers that can be adjusted to produce an aerosol with optimum and reproducible quality based on the feedback information obtained using laser imaging techniques are provides. Two laser-based imaging techniques based on particle image velocimetry (PIV) and optical patternation are provided to map and contrast the size and velocity distributions for indirect and direct pneumatic nebulizations in plasma spectrometry. The flow field of droplets is illuminated by two pulses from a thin laser sheet with a known time difference. The scattering of the laser light from droplets is captured by a charge coupled device (CCD), providing two instantaneous images of the particles. Pointwise cross-correlation of the corresponding images yields a two-dimensional (2-D) velocity map of the aerosol velocity field. For droplet size distribution studies, the solution is doped with a fluorescent dye and both laser induced florescence (LIF) and Mie scattering images are captured simultaneously by two CCDs with the same field of view. The ratio of the LIF / Mie images provides relative droplet size information, which is then scaled by a point calibration method via a phase Doppler particle analyzer (PDPA). Two major outcomes are realized for three nebulization systems: 1) a direct injection high efficiency nebulizer (DIHEN); 2) a large-bore DIHEN (LB-DIHEN); and 3) a PFA microflow nebulizer with a PFA Scott-type spray chamber. First, the central region of the aerosol cone from the direct injection nebulizers and the nebulizer-spray chamber arrangement comprise fast (>13 m / s and >8 m / s, respectively) and fine (<10 μm and <5 μm, respectively) droplets as compared to slow (<4 m / s) and large (>25 μm) droplets in the fringes. Second, the spray chamber acts as a momentum separator, rather than a droplet size selector, as it removes droplets having larger sizes or velocities. Smart-tunable nebulizers may utilize the measured momentum as a feedback control for adjusting certain operation properties of the nebulizer, such as operating conditions and / or critical dimensions.

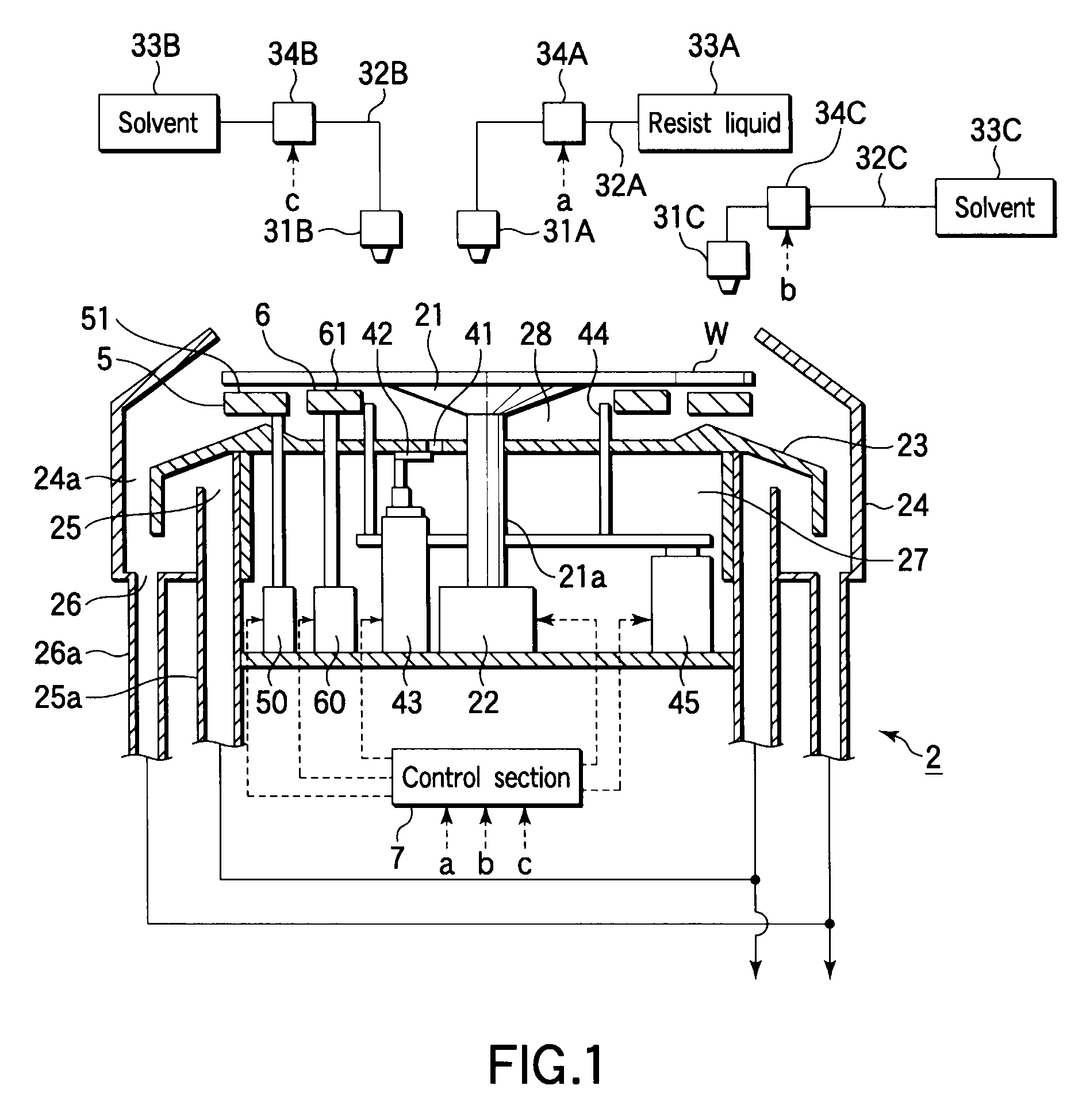

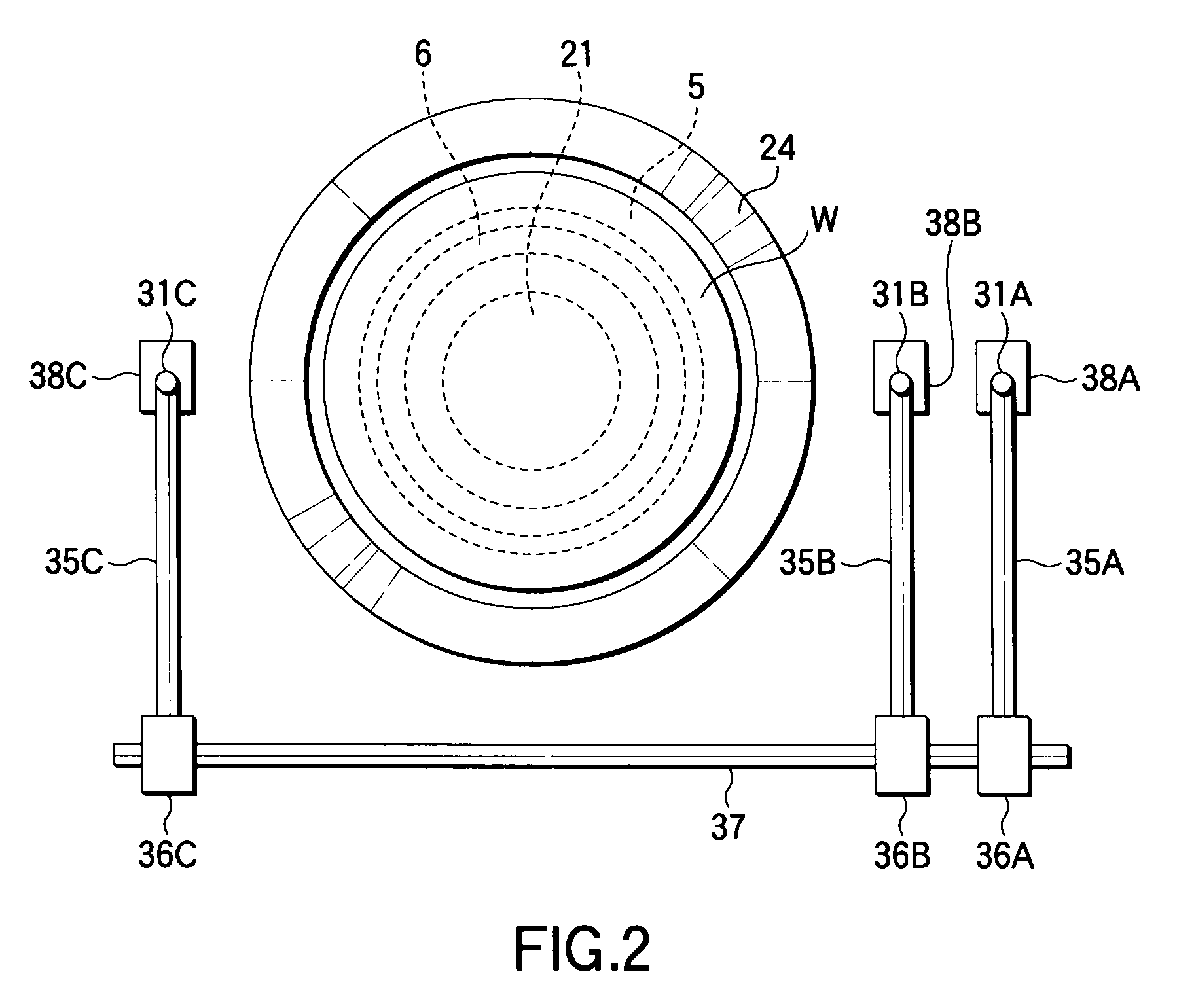

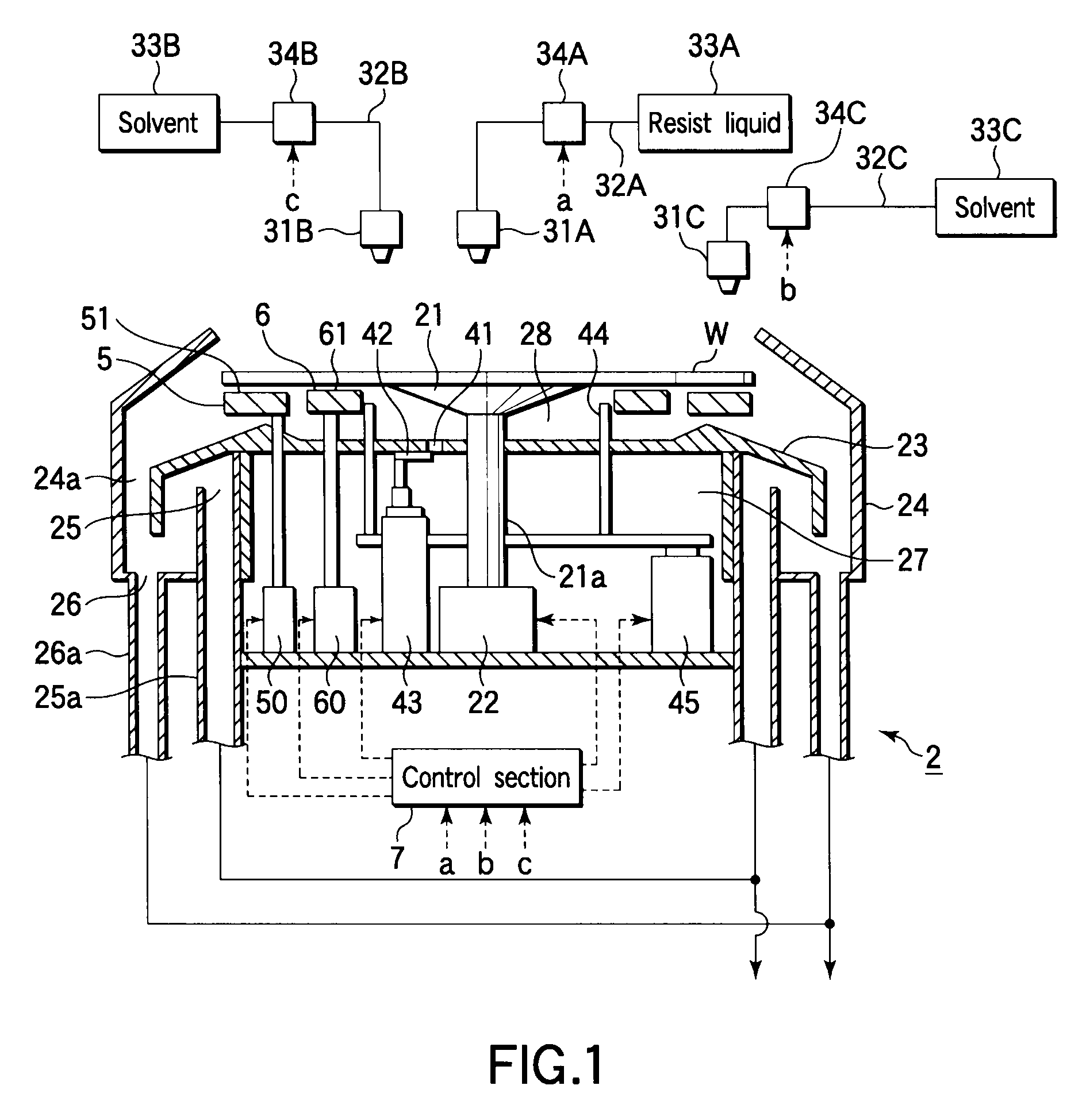

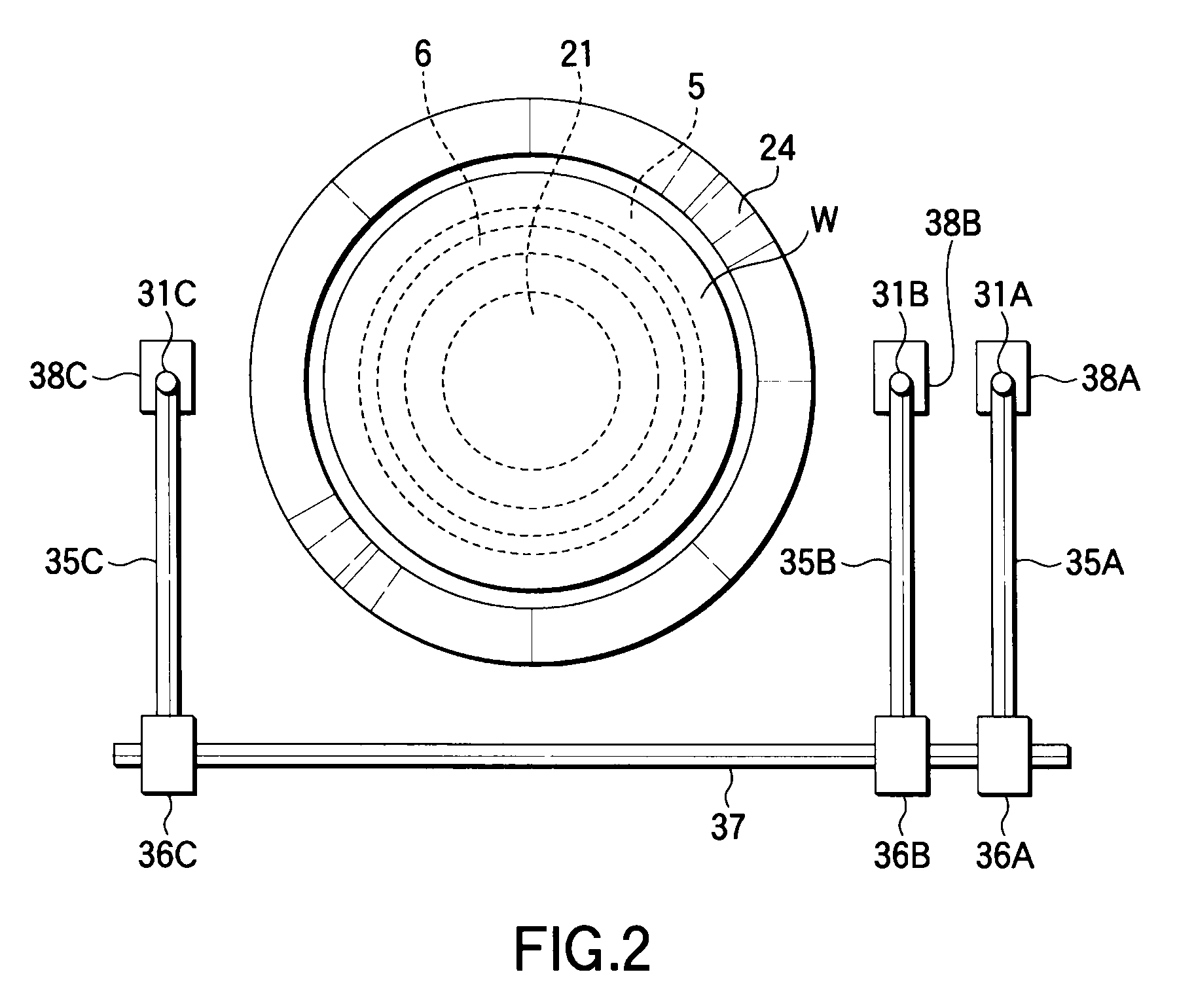

Coating apparatus and method

ActiveUS20090285991A1Reduced solvent consumptionSpraying apparatusPhotomechanical apparatusMechanical engineering

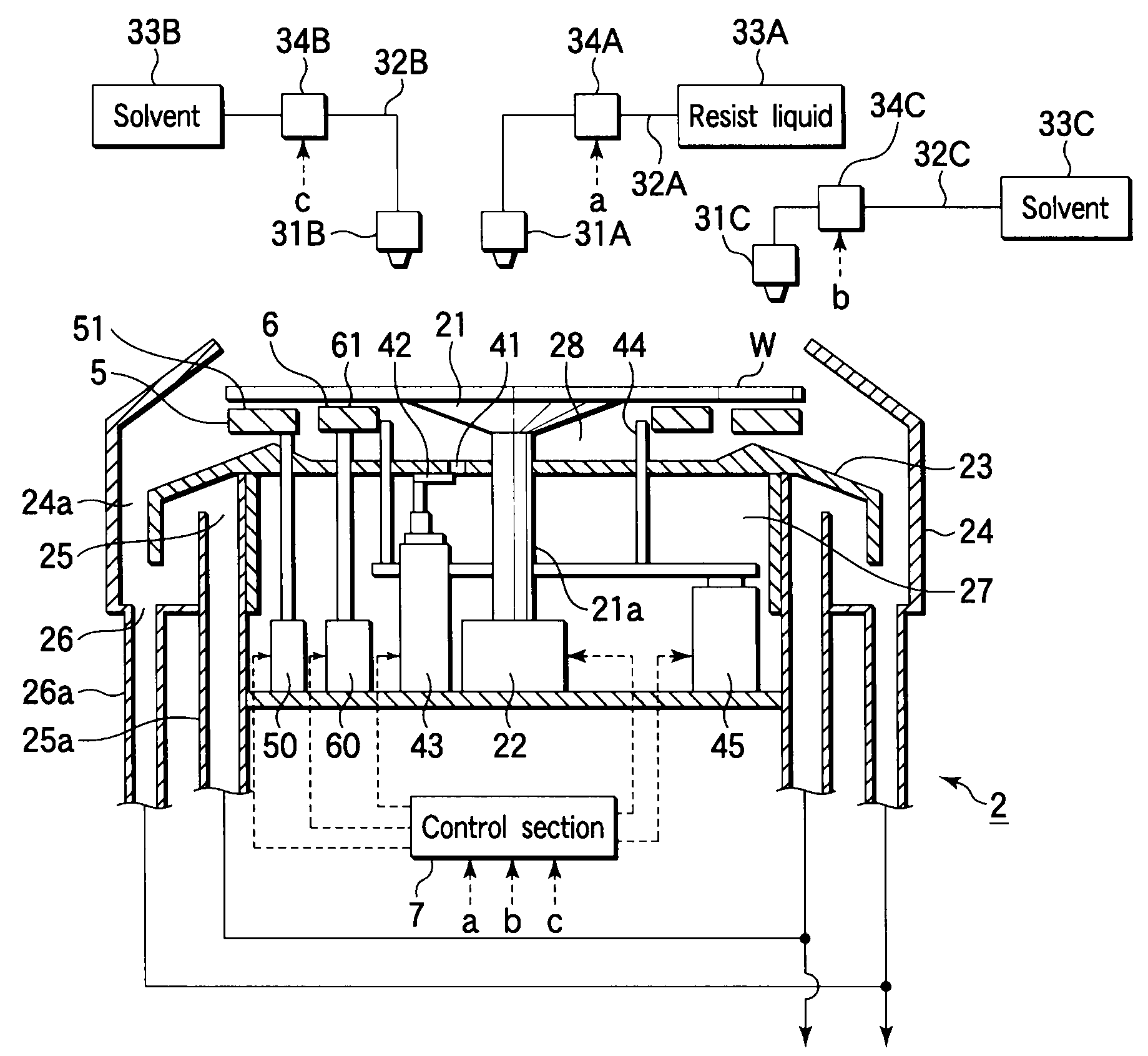

A coating apparatus includes a liquid film forming mechanism configured to form a liquid film of a process liquid for preventing a contaminant derived from a coating liquid from being deposited or left on a back side peripheral portion of a substrate. The liquid film forming mechanism includes a counter face portion facing the back side peripheral portion of the substrate and a process liquid supply portion for supplying the process liquid onto the counter face portion. The coating apparatus further includes a posture regulating mechanism disposed around the substrate holding member and configured to damp a vertical wobble of the peripheral portion of the substrate being rotated. The posture regulating mechanism includes delivery holes arrayed in a rotational direction of the substrate and configured to deliver a gas onto a back side region of the substrate on an inner side of the peripheral portion.

Owner:TOKYO ELECTRON LTD

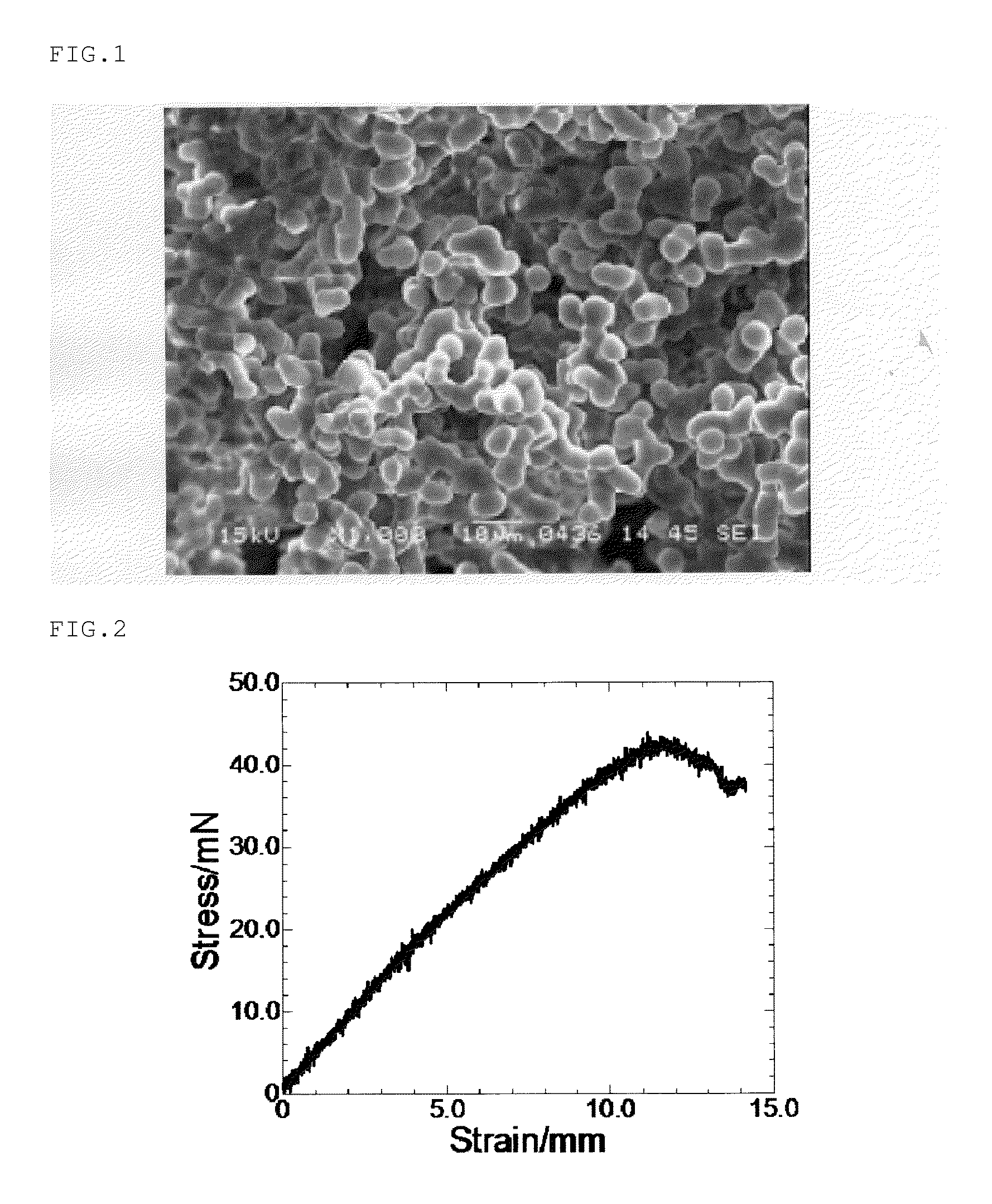

Process for the Production of an Aerogel Material

InactiveUS20160258153A1Increase productionEasy to manufactureHeat proofingSilicon compoundsSilicon oxideSolvent

A process for the production of an aerogel material comprises the following steps:a) preparation of a silicon oxide sol in an alcoholic solvent mixture;b) triggering of the gelation of the sol by adding base, whereby a gel is formed, and optionally aging of the gel;c) hydrophobicization of the optionally aged gel;d) removal of the solvent mixture by subcritical drying, whereby the aerogel material is formed.The silicon oxide sol formed in step a) comprises at least one acid-catalytically activatable hydrophobicization agent, wherein the volume fraction of the hydrophobicization agent in the sol is 5 to 60%. The hydrophobicization in step c) is induced as a result of release or addition of at least one hydrophobicization catalyst acting in combination with the hydrophobicization agent.

Owner:EMPA EIDGENOESSISCHE MATERIALPRFUNGS & FORSCHUNGSANSTALT

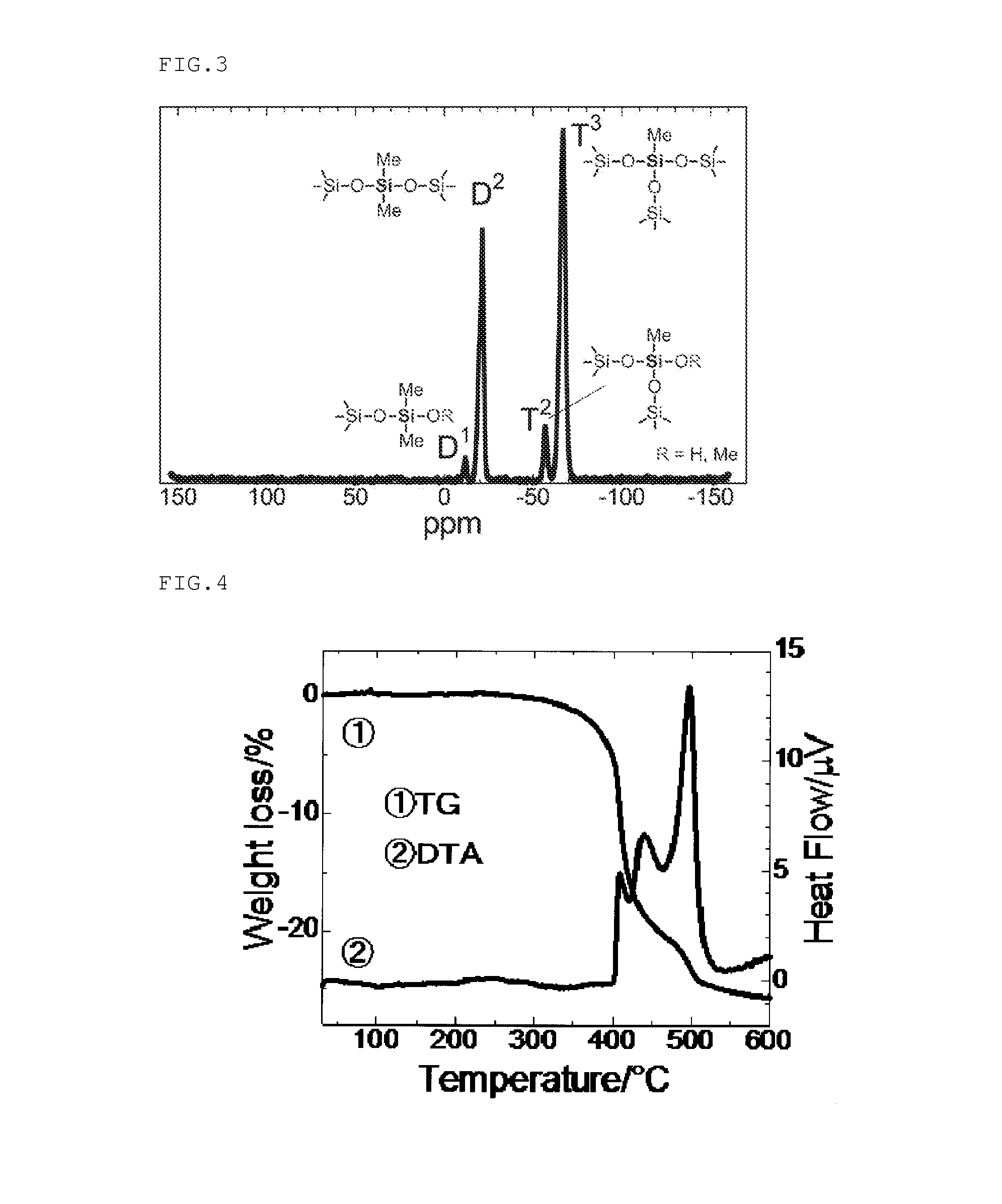

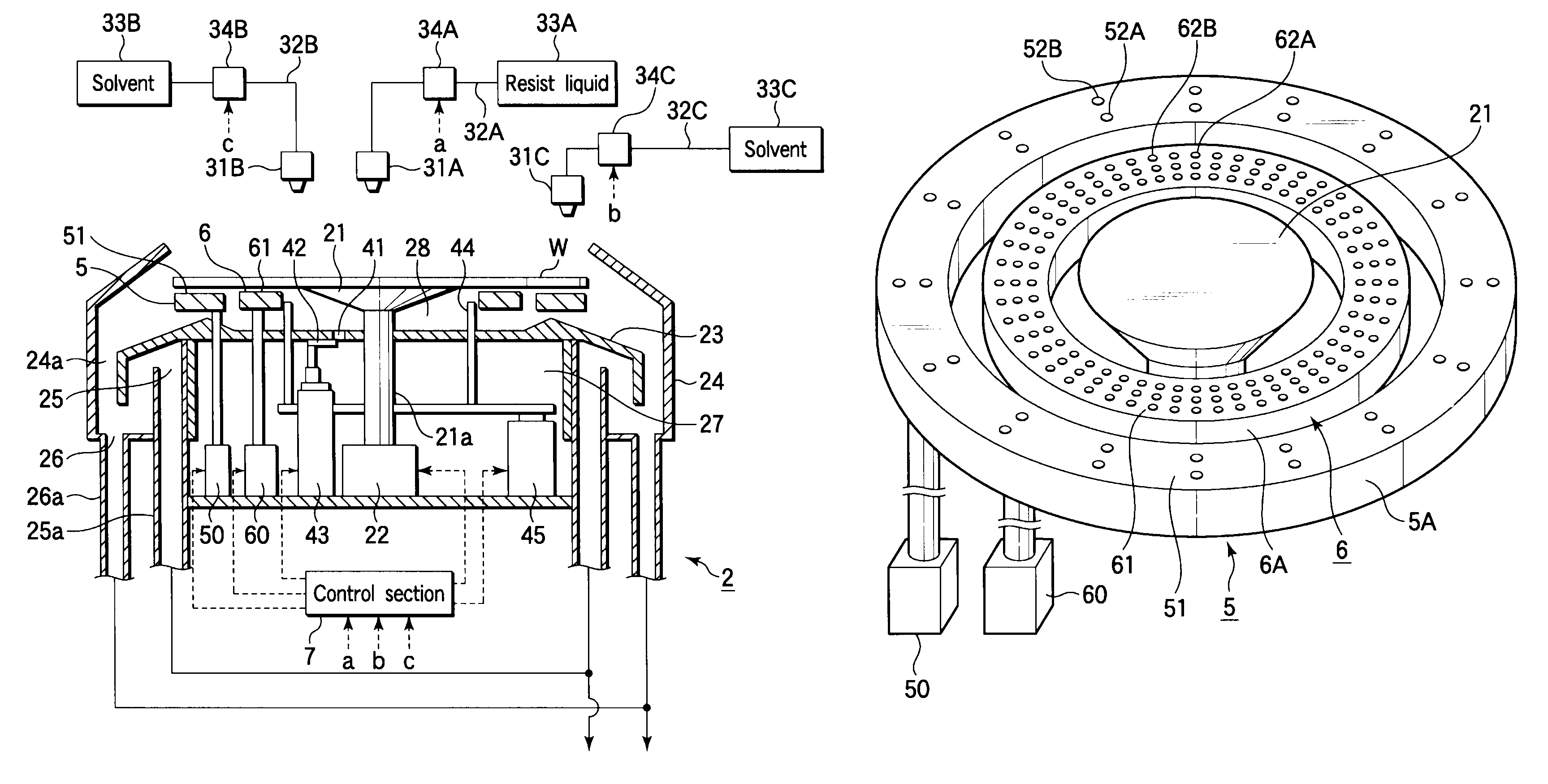

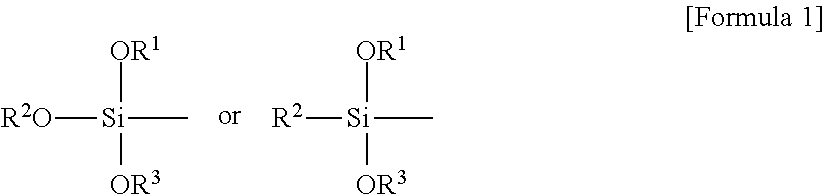

Monolithic silicone and method of separation, purification and concentration therewith

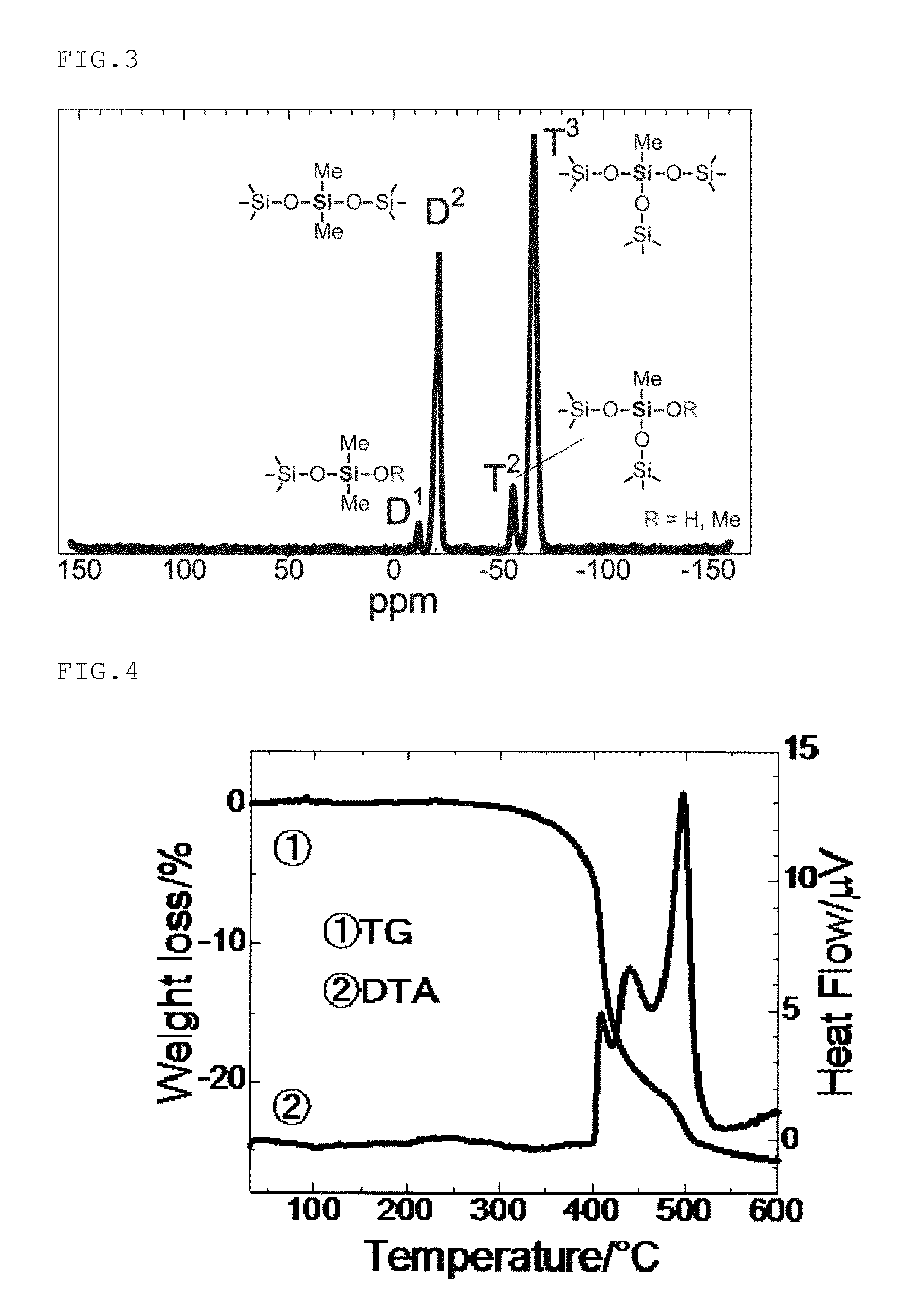

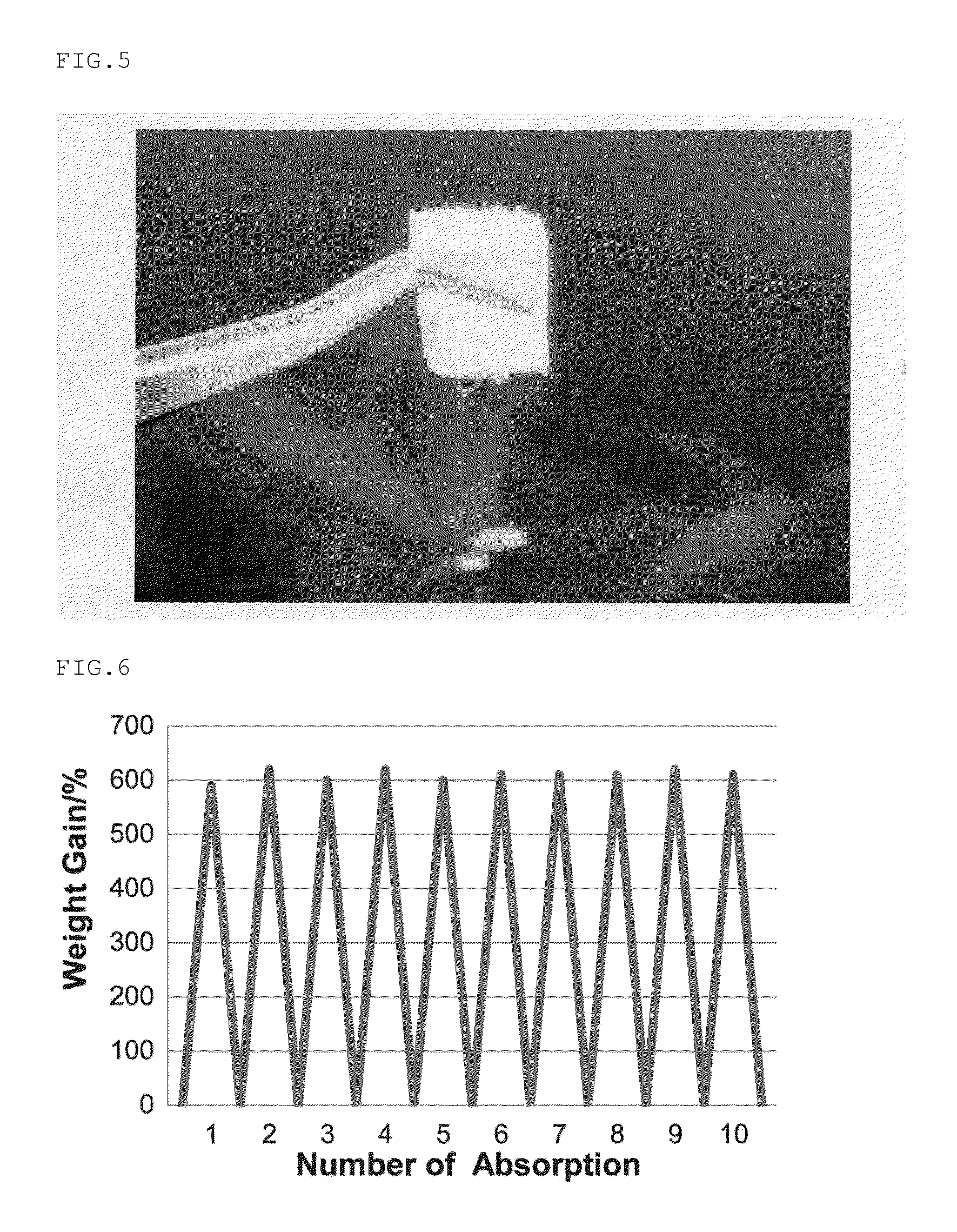

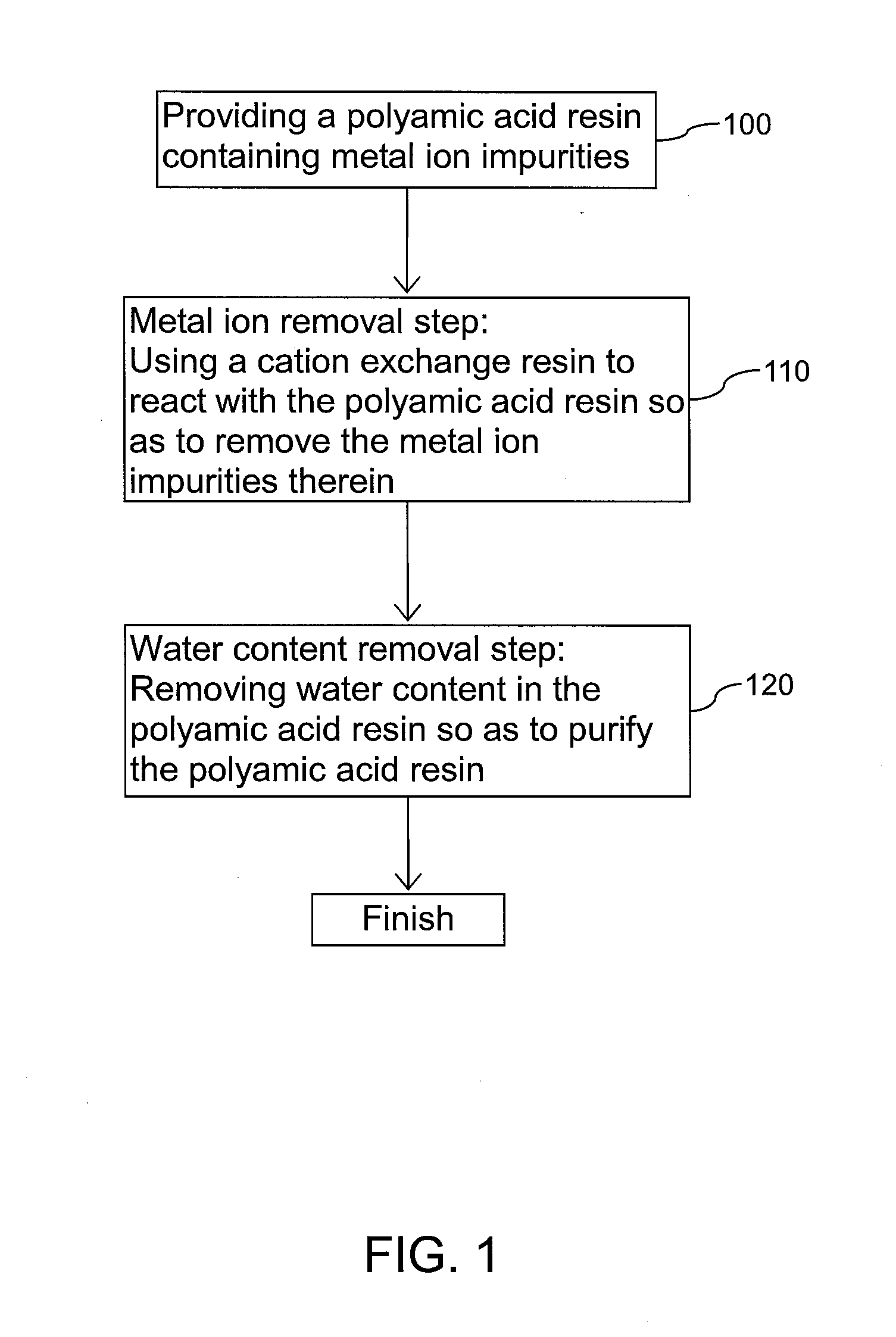

ActiveUS20140076070A1Increase flexibilityHigh porosityWithdrawing sample devicesPreparing sample for investigationSolventPolymer chemistry

The present invention provides a monolithic silicone in the form of an aerogel or a xerogel having flexibility and capable of dissolving molecules of a substance. This silicone monolithic body having continuous through passages is synthesized by copolymerizing starting materials of both a bifunctional alkoxysilane and a trifunctional alkoxysilane or tri- or higher functional alkoxysilanes through a sol-gel reaction for forming a Si—O network while causing phase separation.

Owner:KYOTO UNIV +1

Coating apparatus and method

ActiveUS8256370B2Reduced solvent consumptionSpraying apparatusPhotomechanical apparatusMechanical engineering

A coating apparatus includes a liquid film forming mechanism configured to form a liquid film of a process liquid for preventing a contaminant derived from a coating liquid from being deposited or left on a back side peripheral portion of a substrate. The liquid film forming mechanism includes a counter face portion facing the back side peripheral portion of the substrate and a process liquid supply portion for supplying the process liquid onto the counter face portion. The coating apparatus further includes a posture regulating mechanism disposed around the substrate holding member and configured to damp a vertical wobble of the peripheral portion of the substrate being rotated. The posture regulating mechanism includes delivery holes arrayed in a rotational direction of the substrate and configured to deliver a gas onto a back side region of the substrate on an inner side of the peripheral portion.

Owner:TOKYO ELECTRON LTD

Pressure-sensitive adhesive composition for use on an optical film, pressure-sensitive adhesive layer, pressure-sensitive adhesive layer-carrying optical film, and image display device

InactiveUS20130288048A1High removabilityHigh durabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPressure sensitive

A pressure-sensitive adhesive composition for use on an optical film, includes a (meth)acryl-based polymer obtained by copolymerization of 30 to 98.9% by weight of an alkyl(meth)acrylate, 1 to 50% by weight of an aromatic ring-containing polymerizable monomer, 0.1 to 20% by weight of a hydroxyl group-containing monomer, and 0 to 4% by weight of a carboxyl group-containing monomer, and a solvent. The (meth)acryl-based polymer has a weight average molecular weight of 300,000 to 1,200,000 as measured by gel permeation chromatography. The content of a solid including the (meth)acryl-based polymer is 20% by weight or more, and the content of the solvent is 80% by weight or less.

Owner:NITTO DENKO CORP

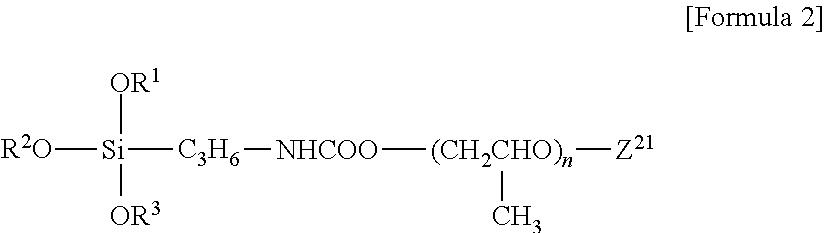

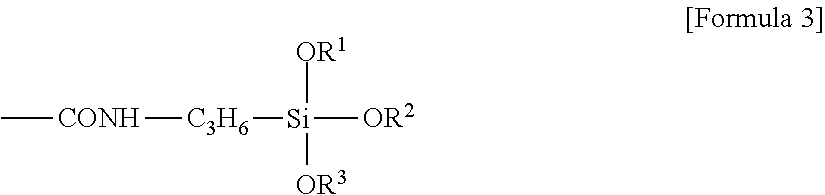

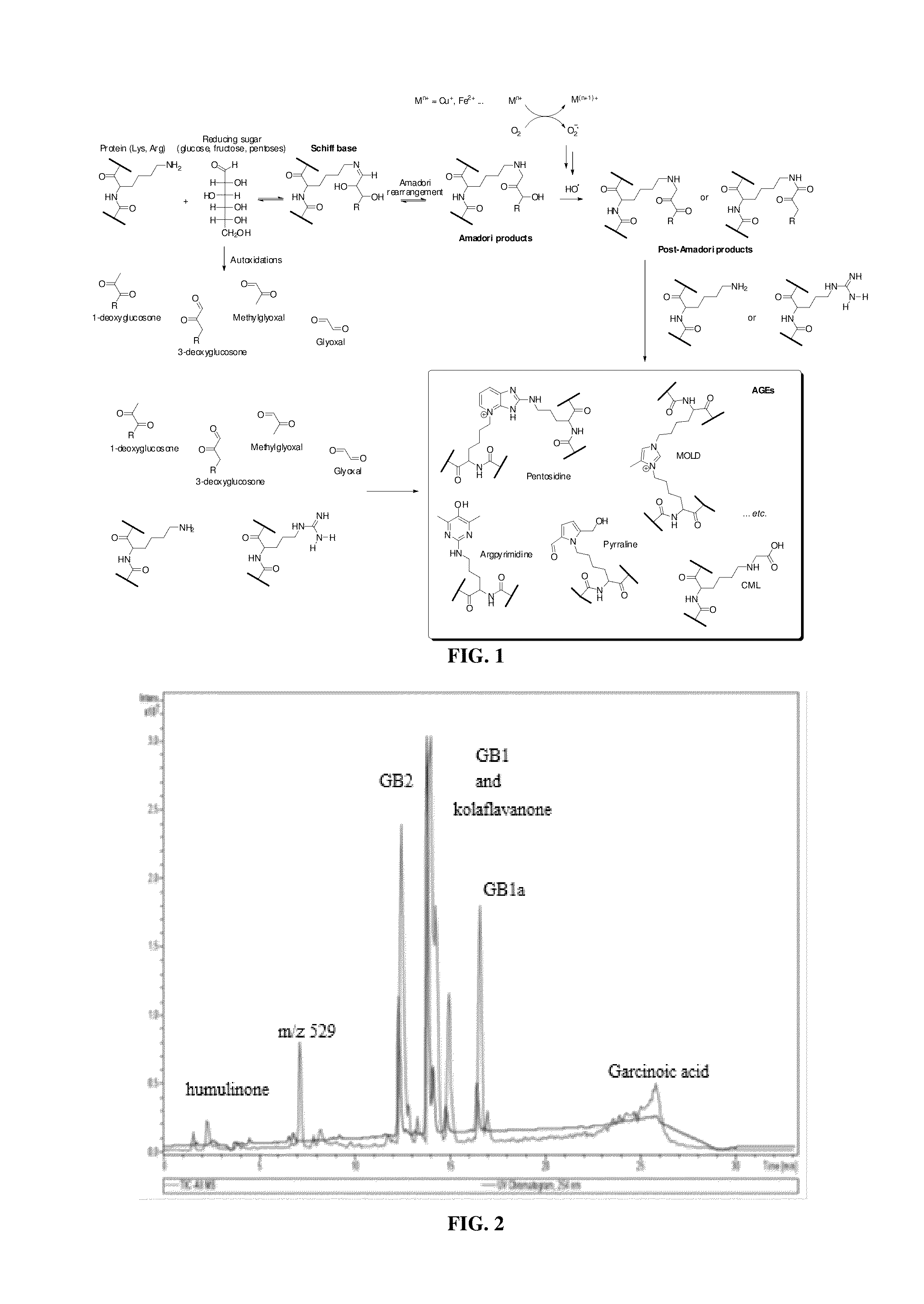

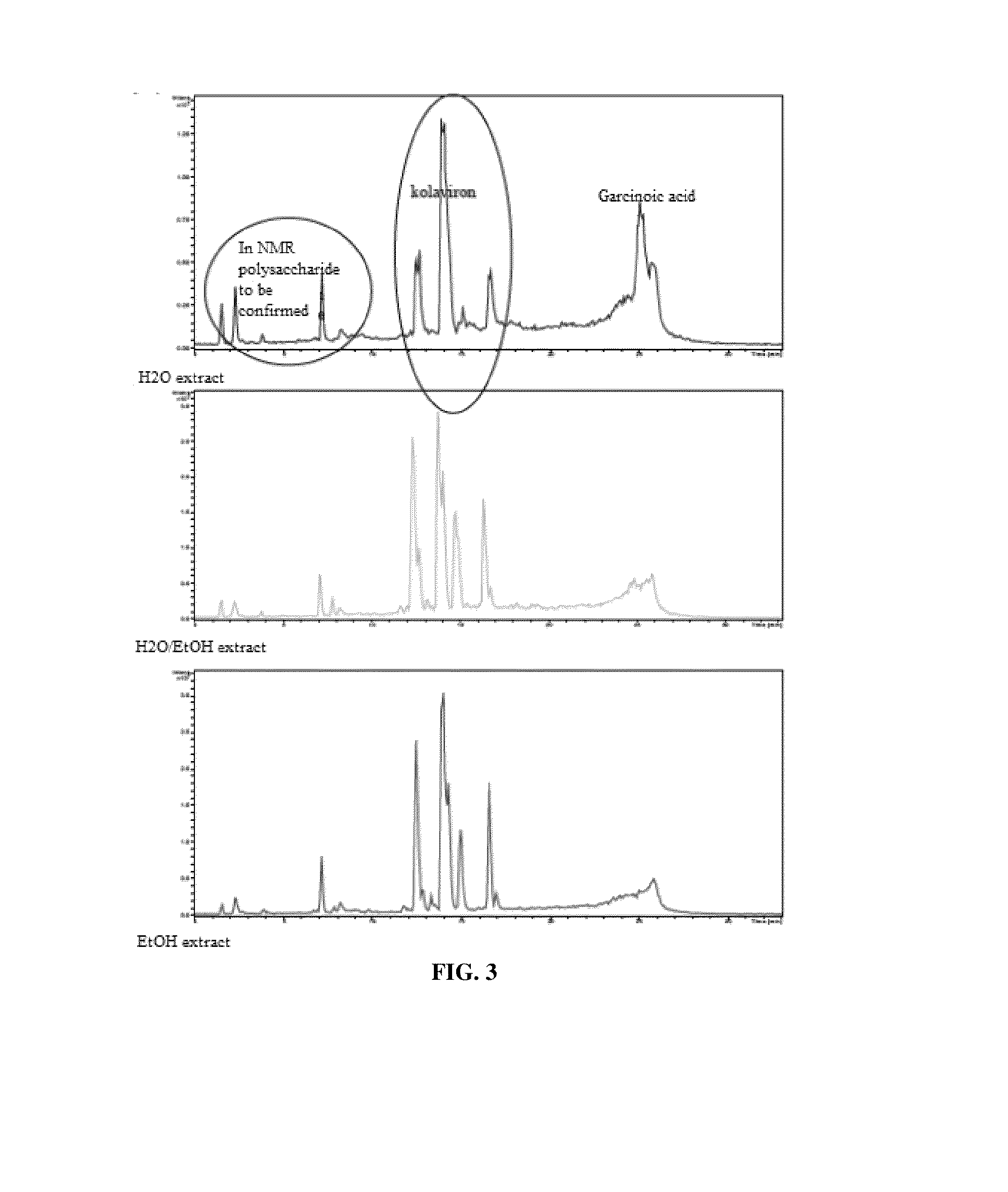

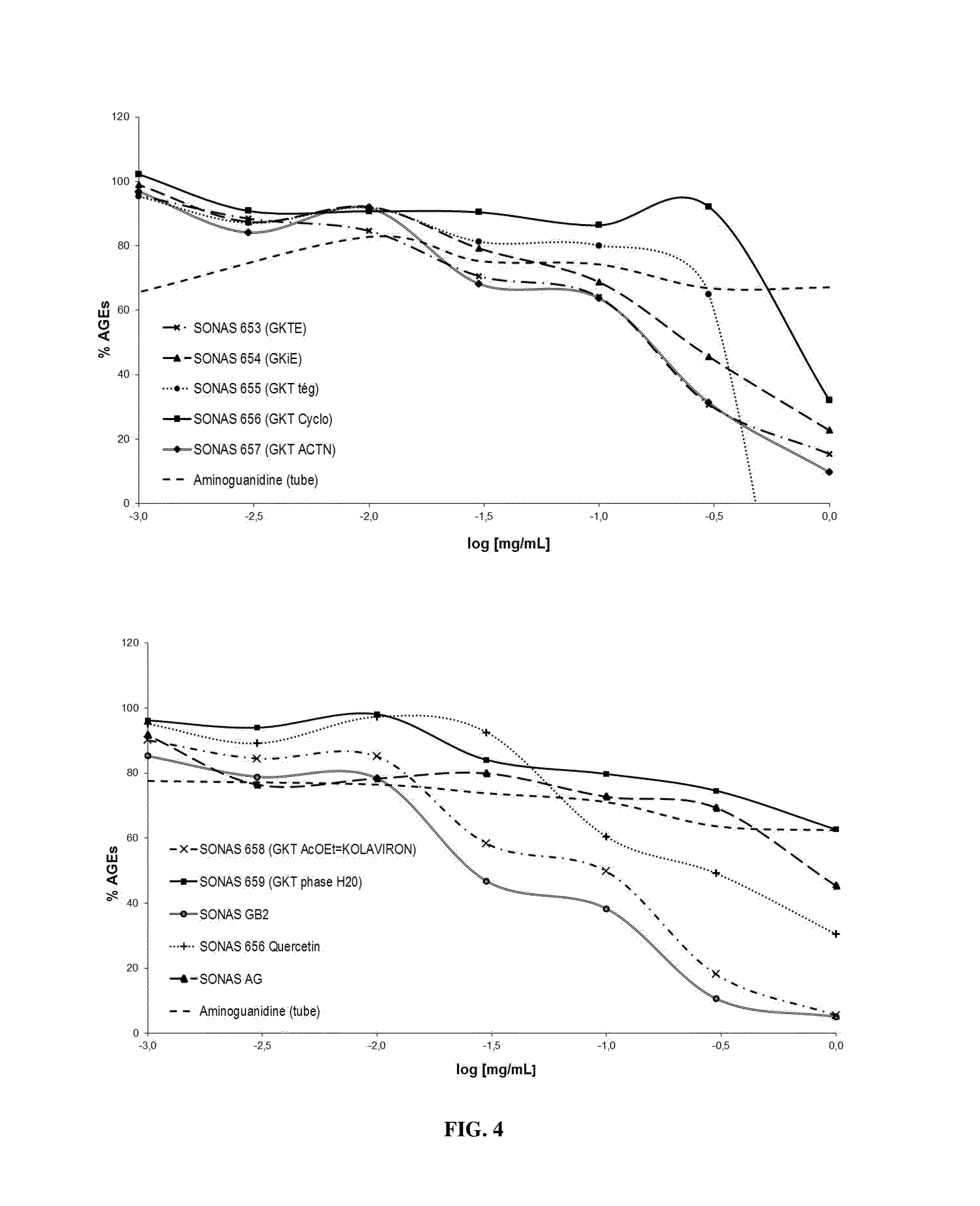

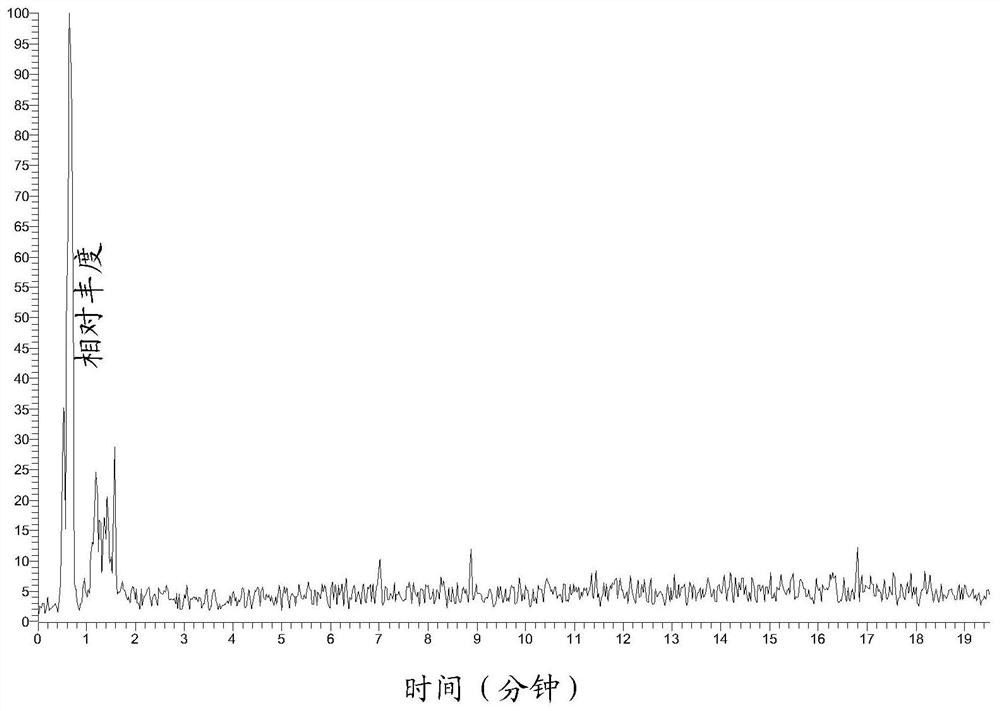

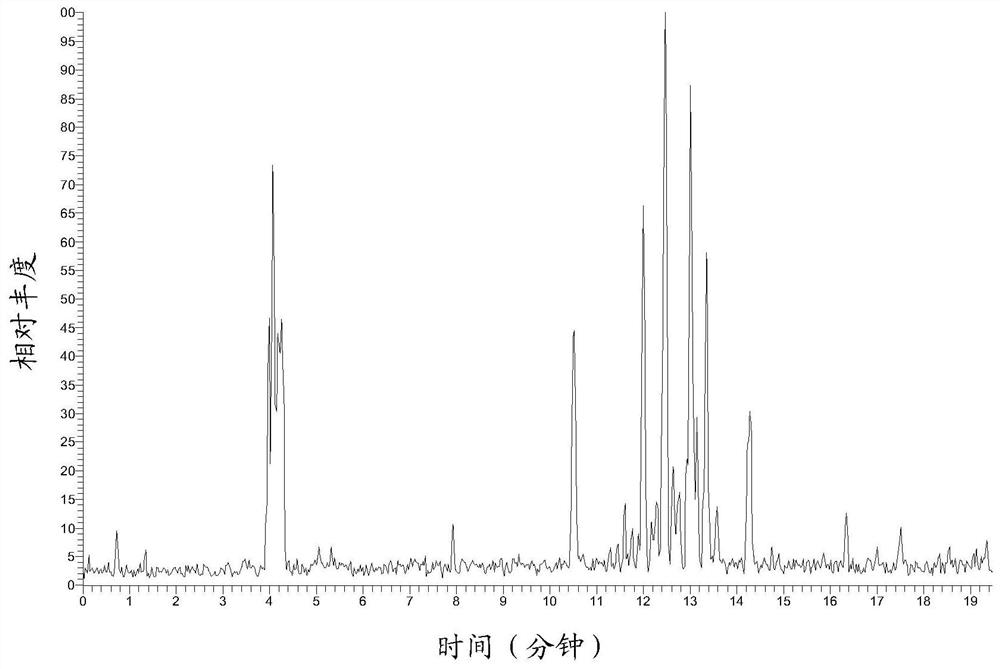

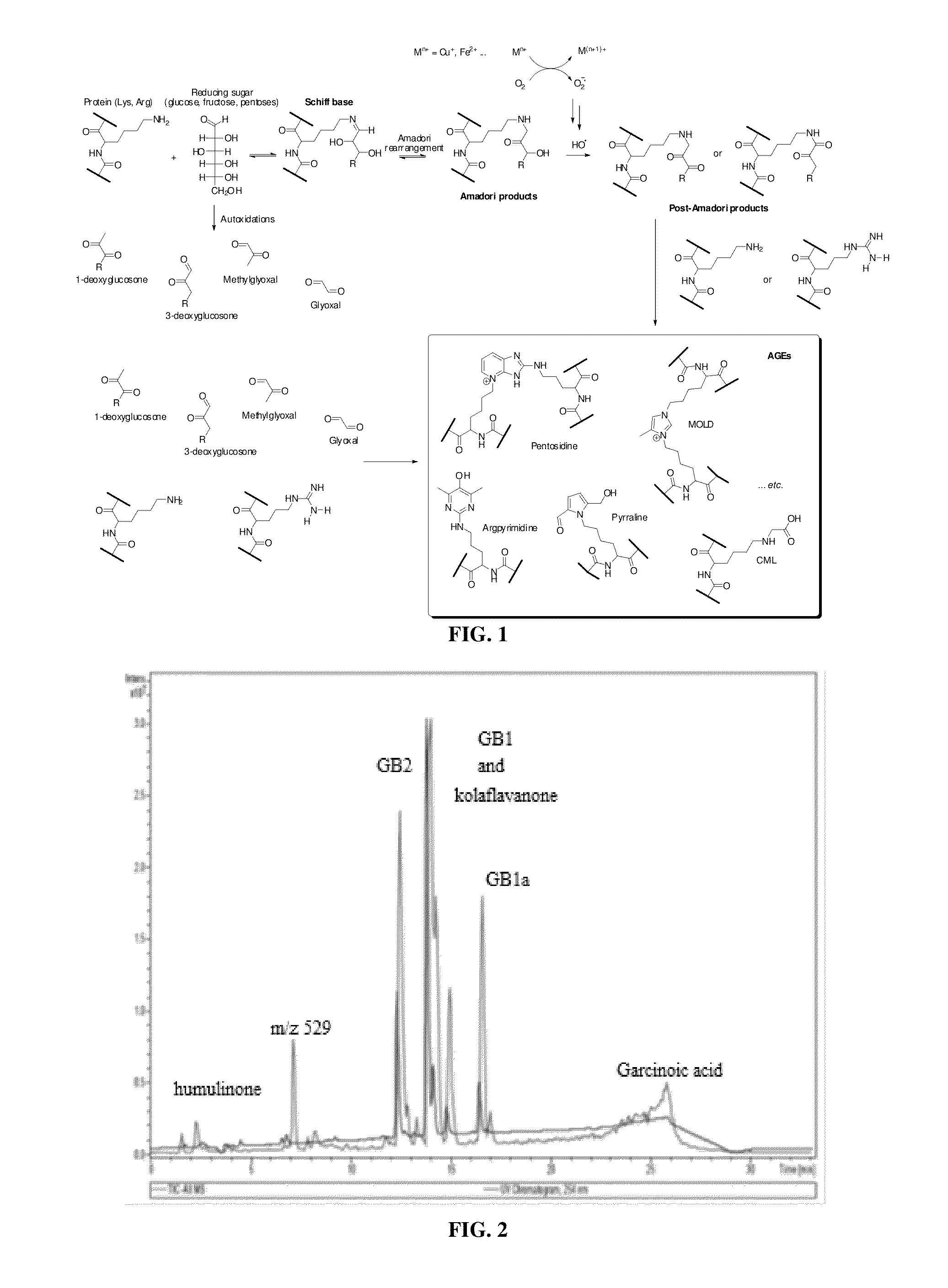

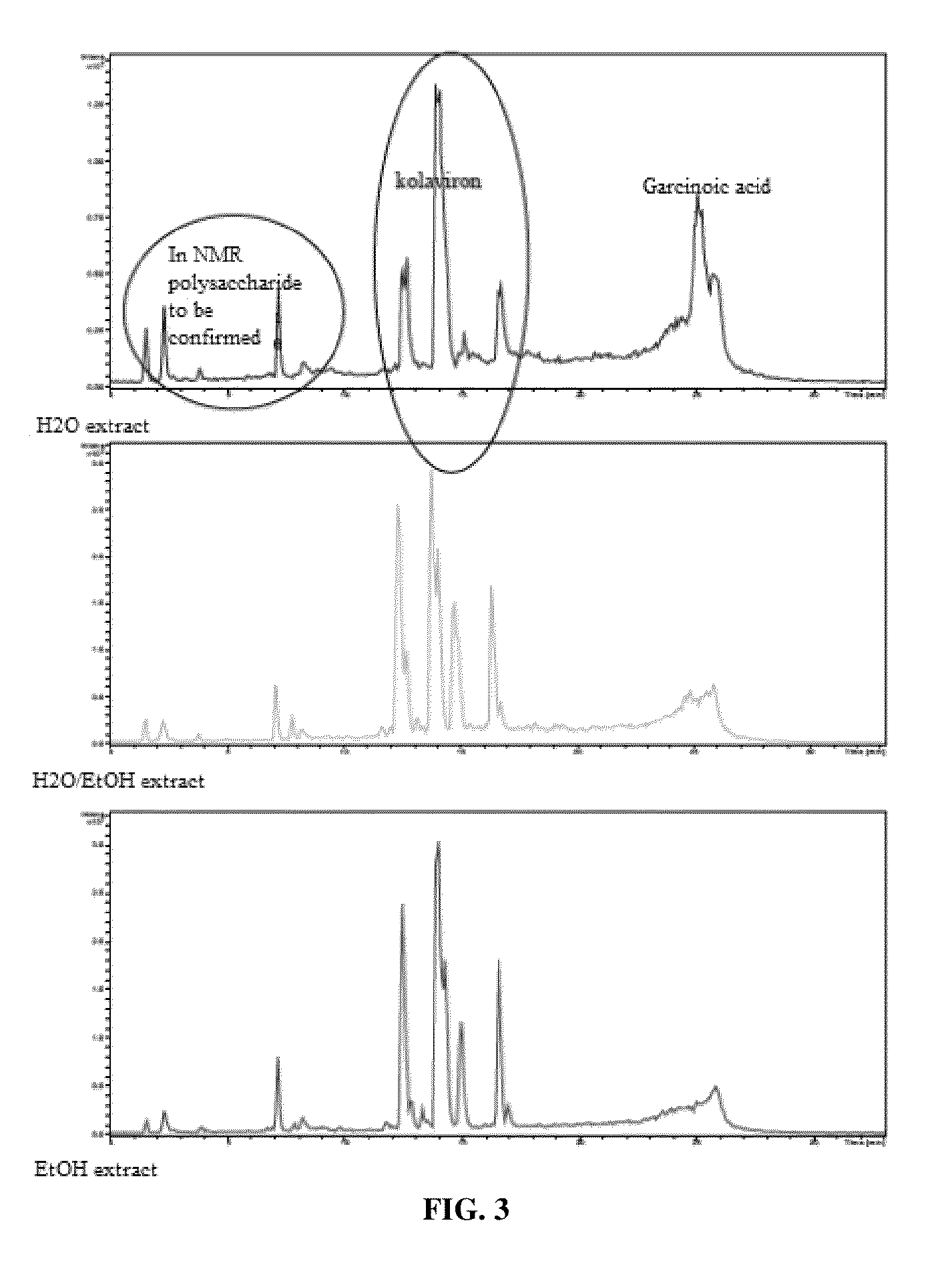

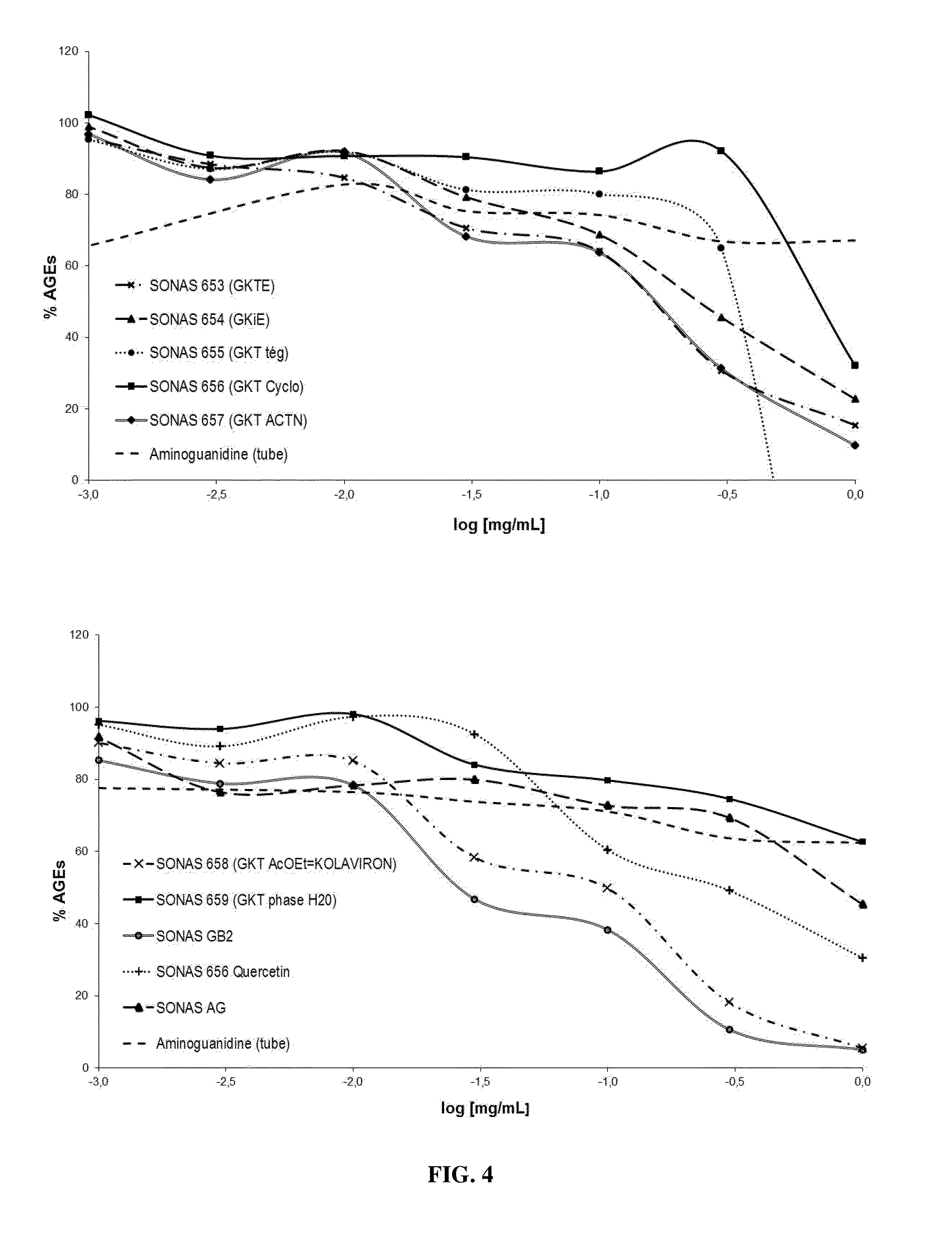

Anti-glycation agent comprising a garcinia kola extract or fraction

ActiveUS20140142171A1Reduced solvent consumptionImprove solubilityBiocideCosmetic preparationsAnti glycationSkin Aging

An anti-glycation agent includes a Garcinia kola extract or fraction. The compositions including the extract or the fraction are used to inhibit the glycation of proteins, in particular the glycation of skin proteins involved in cutaneous aging. A method for determining the activity of compounds for inhibiting the glycation of cutaneous proteins, in particular for inhibiting the glycation of collagen is also described.

Owner:UNIV DANGERS +1

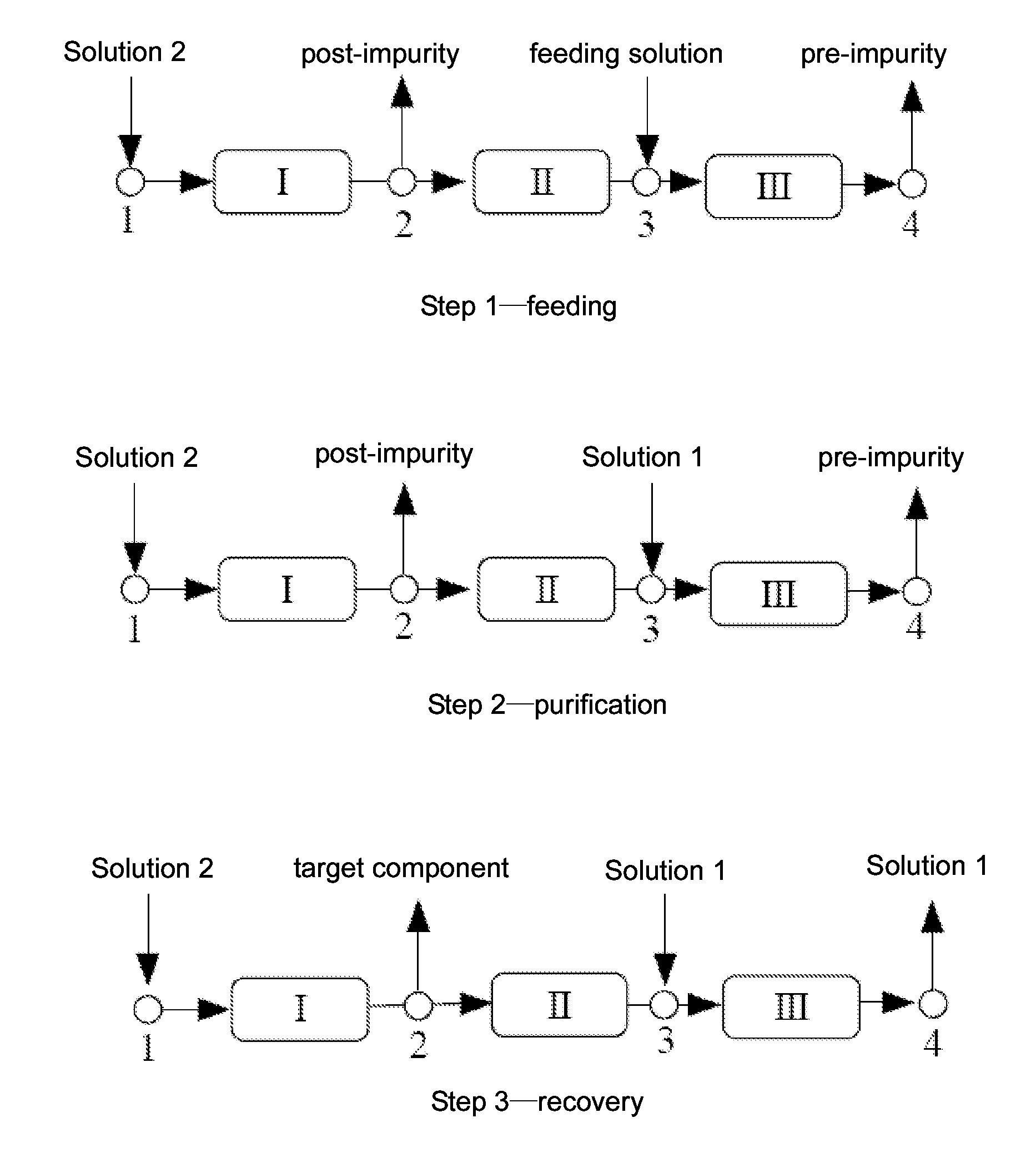

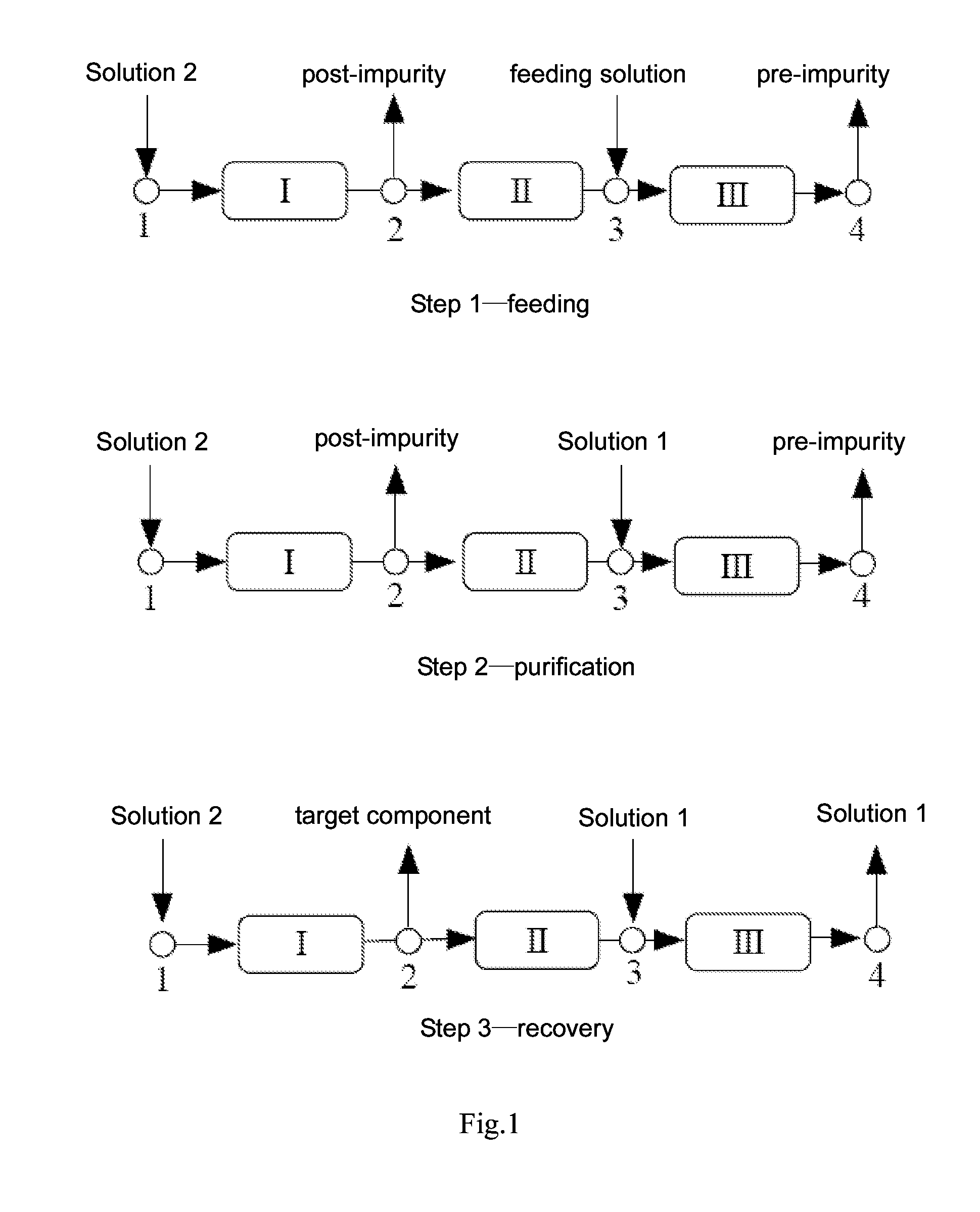

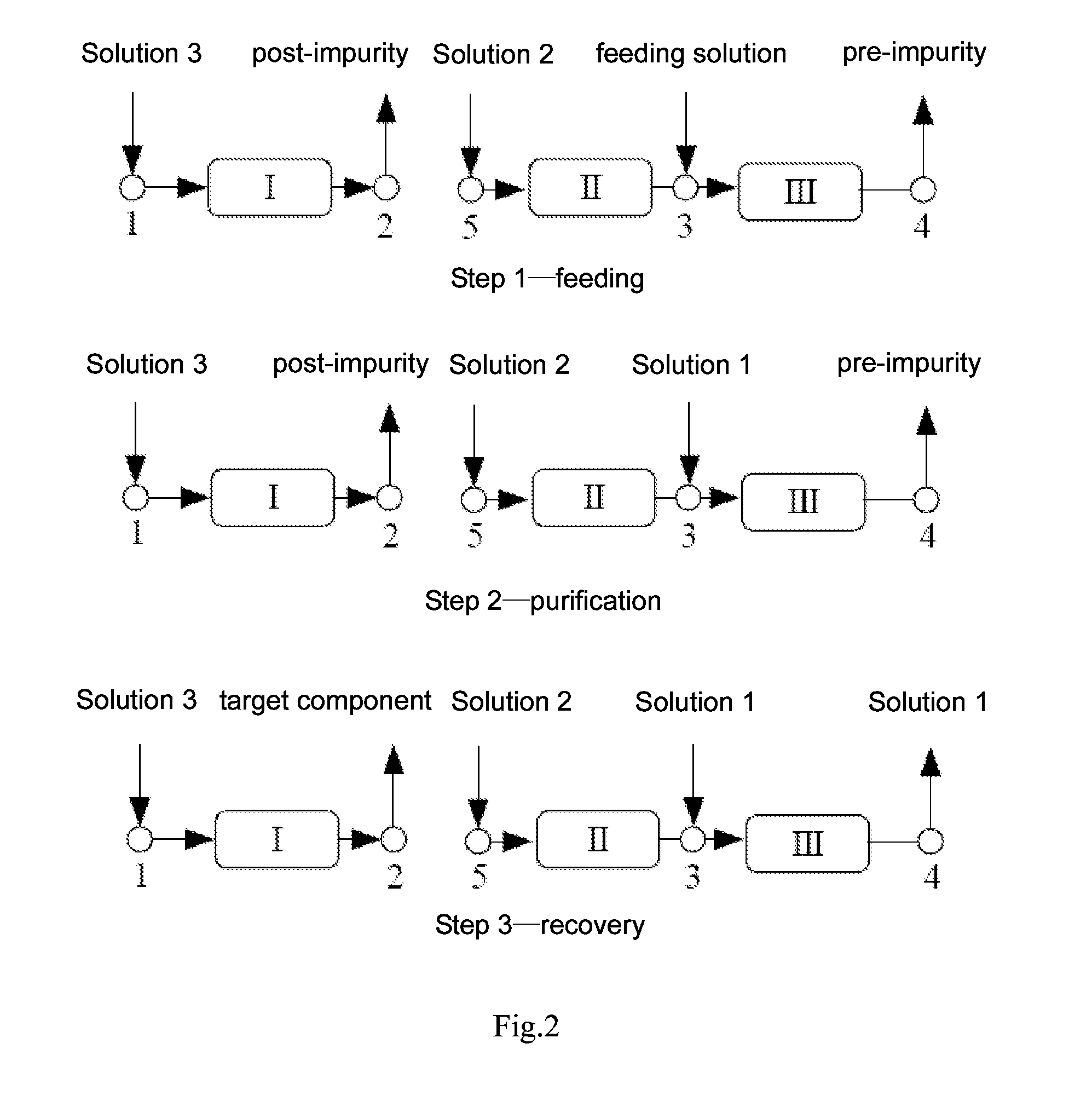

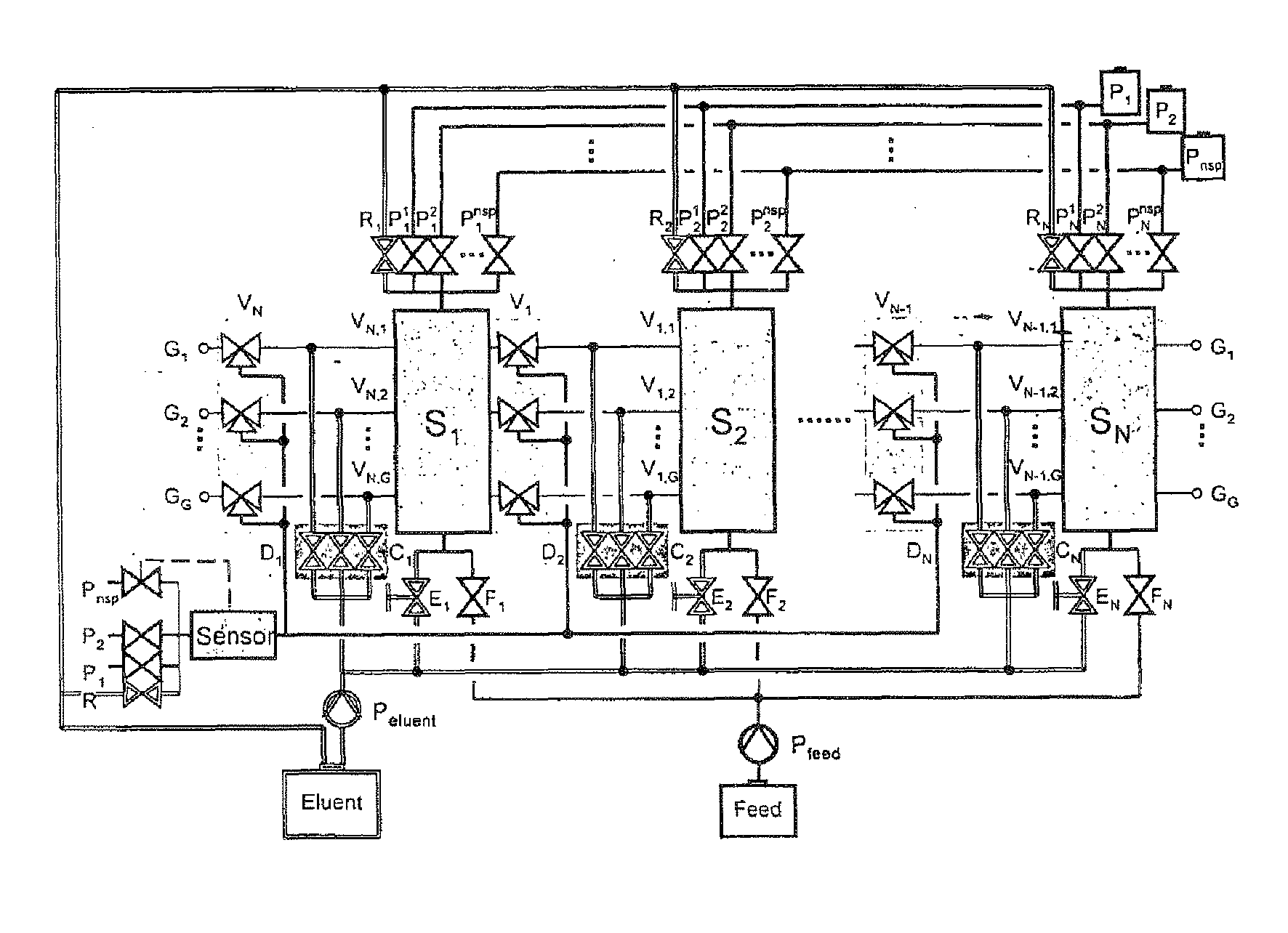

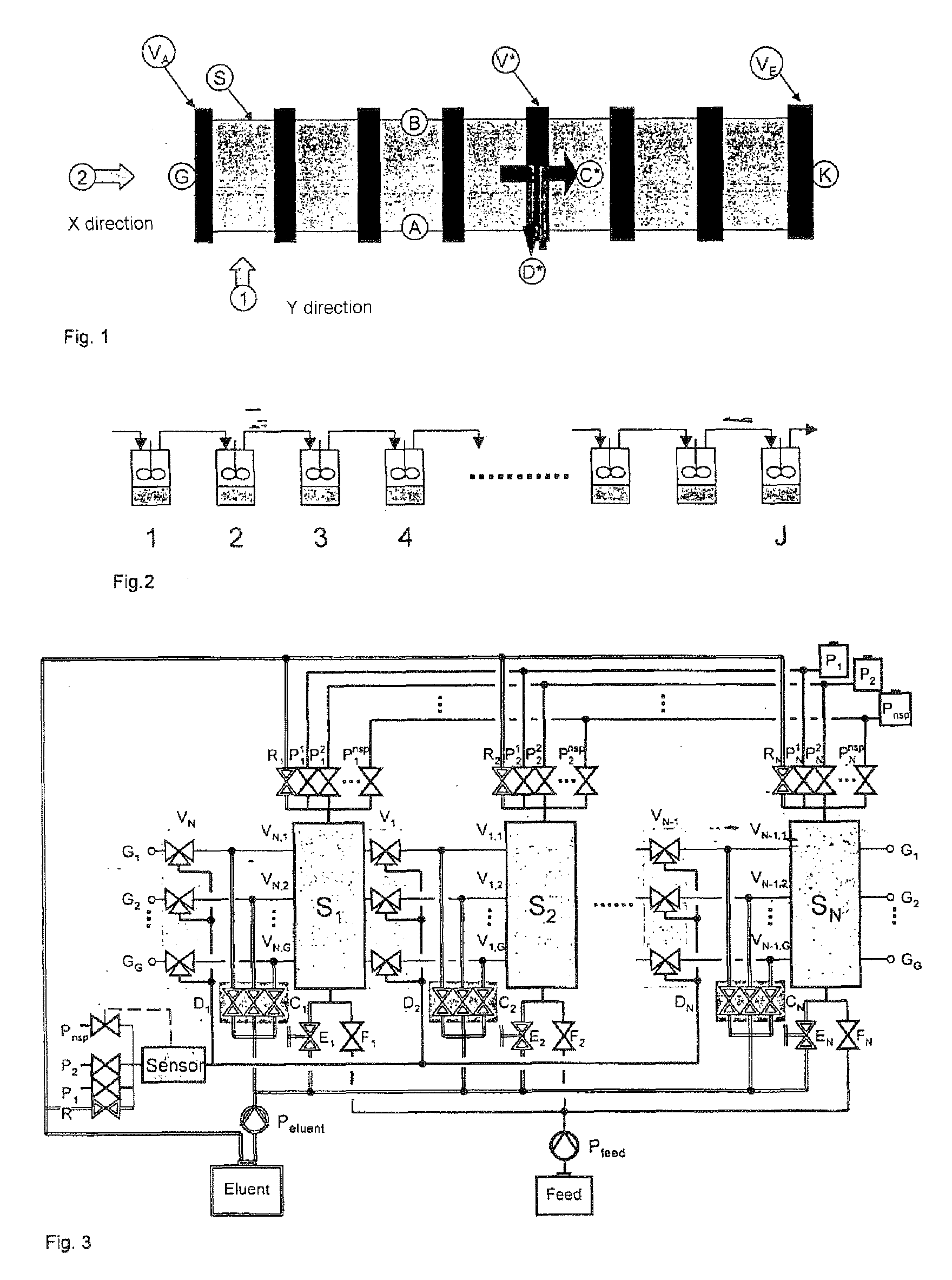

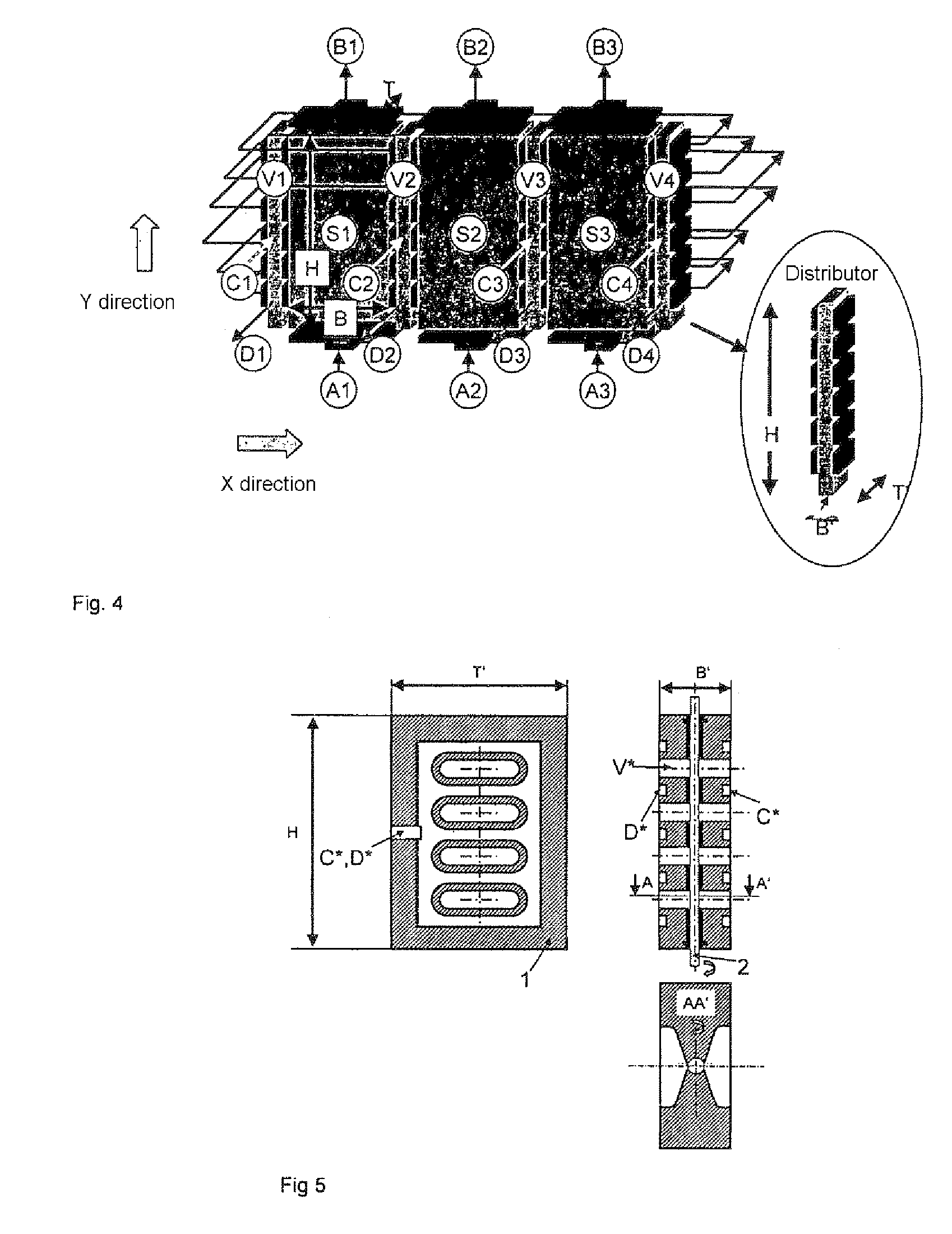

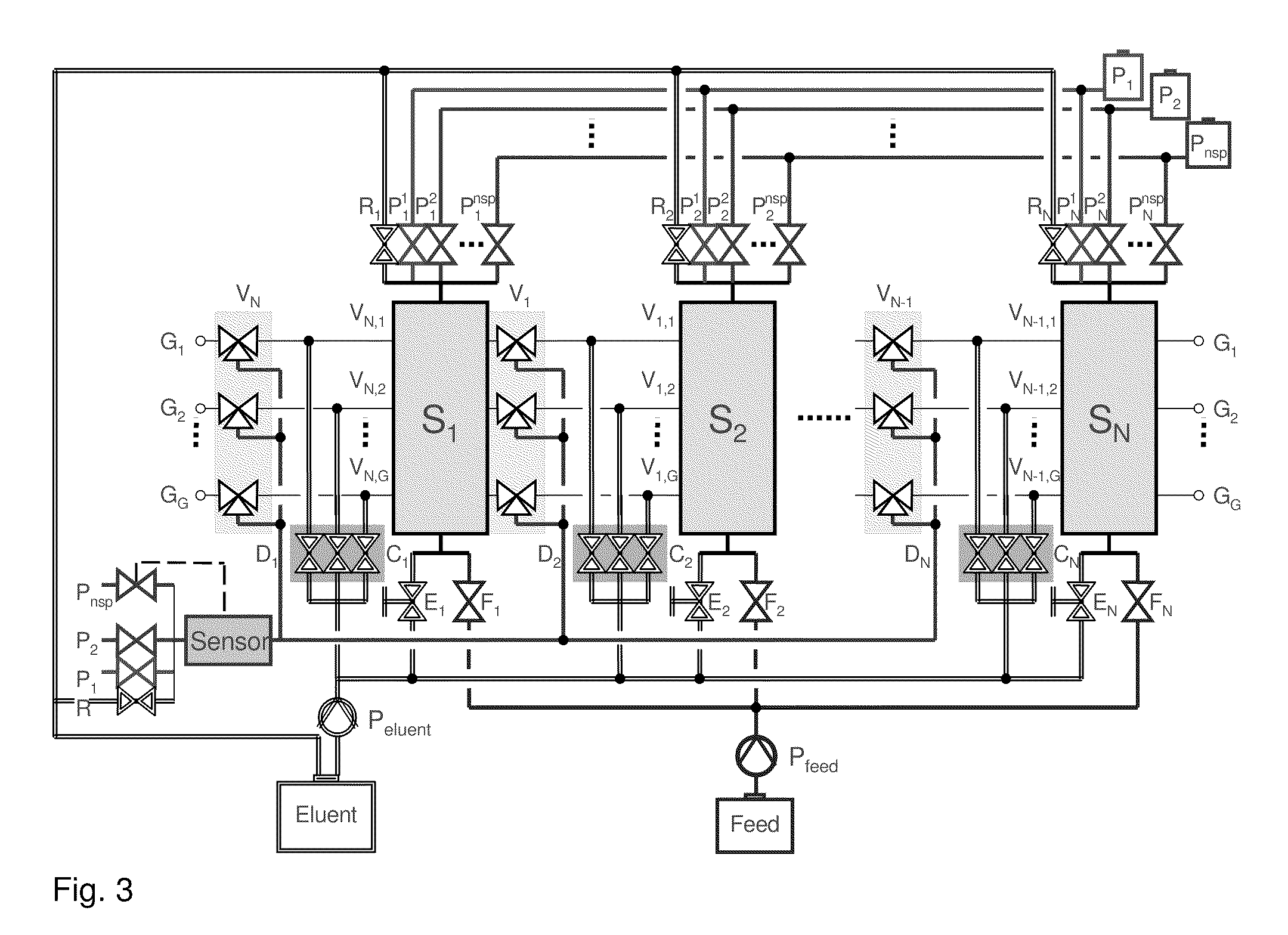

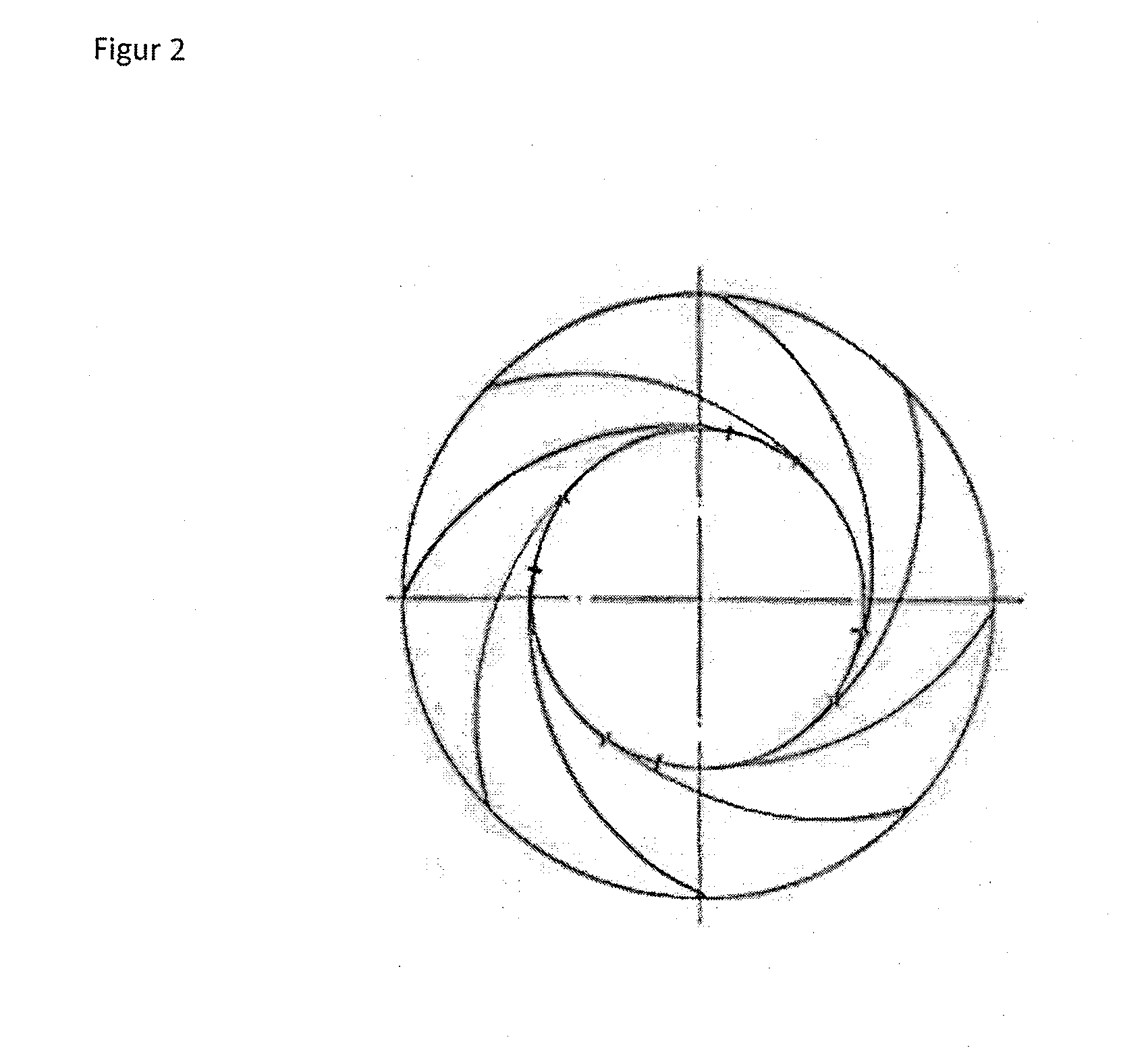

Method for separating a mixture comprising three components by simulated moving bed chromatography

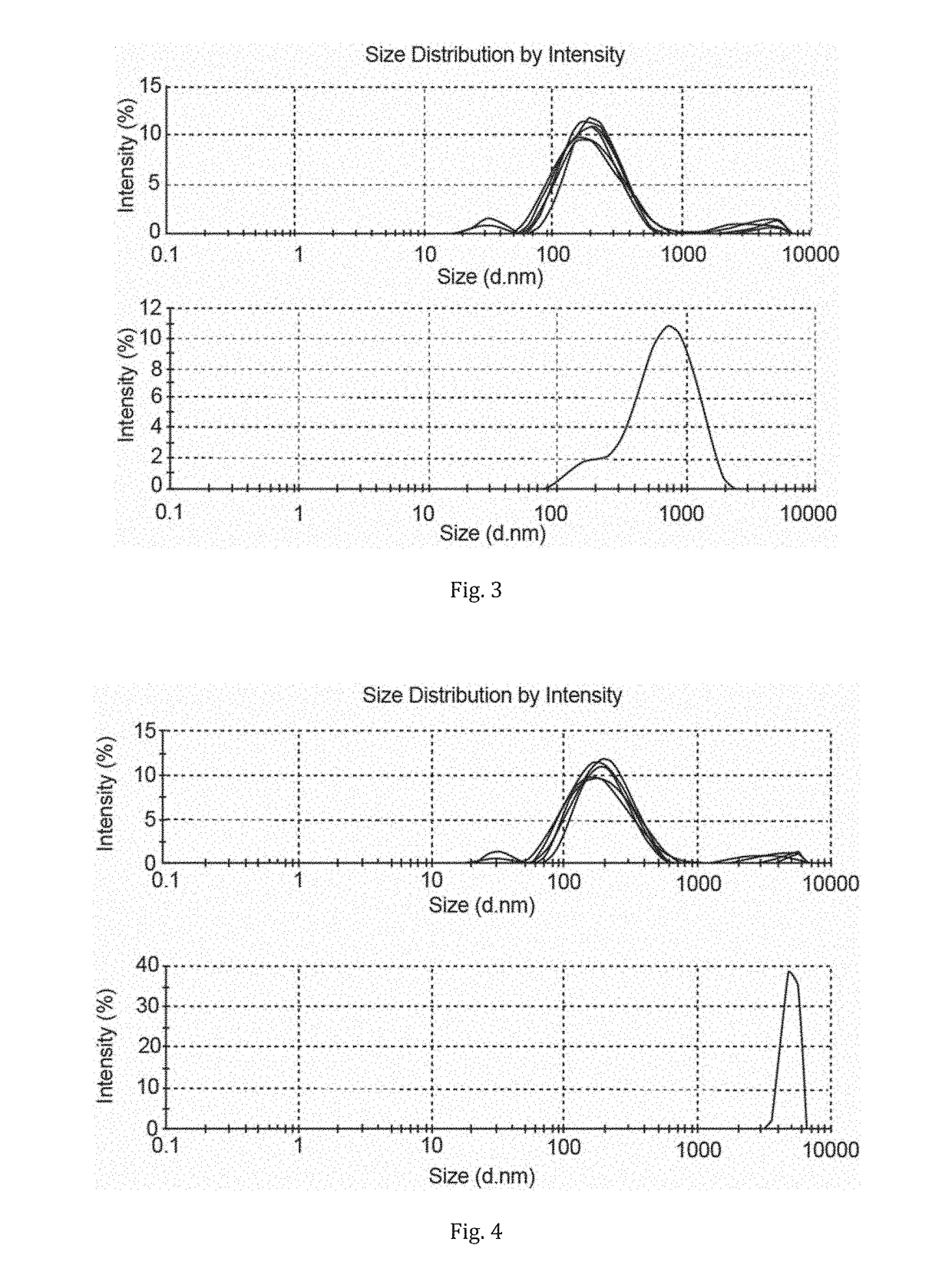

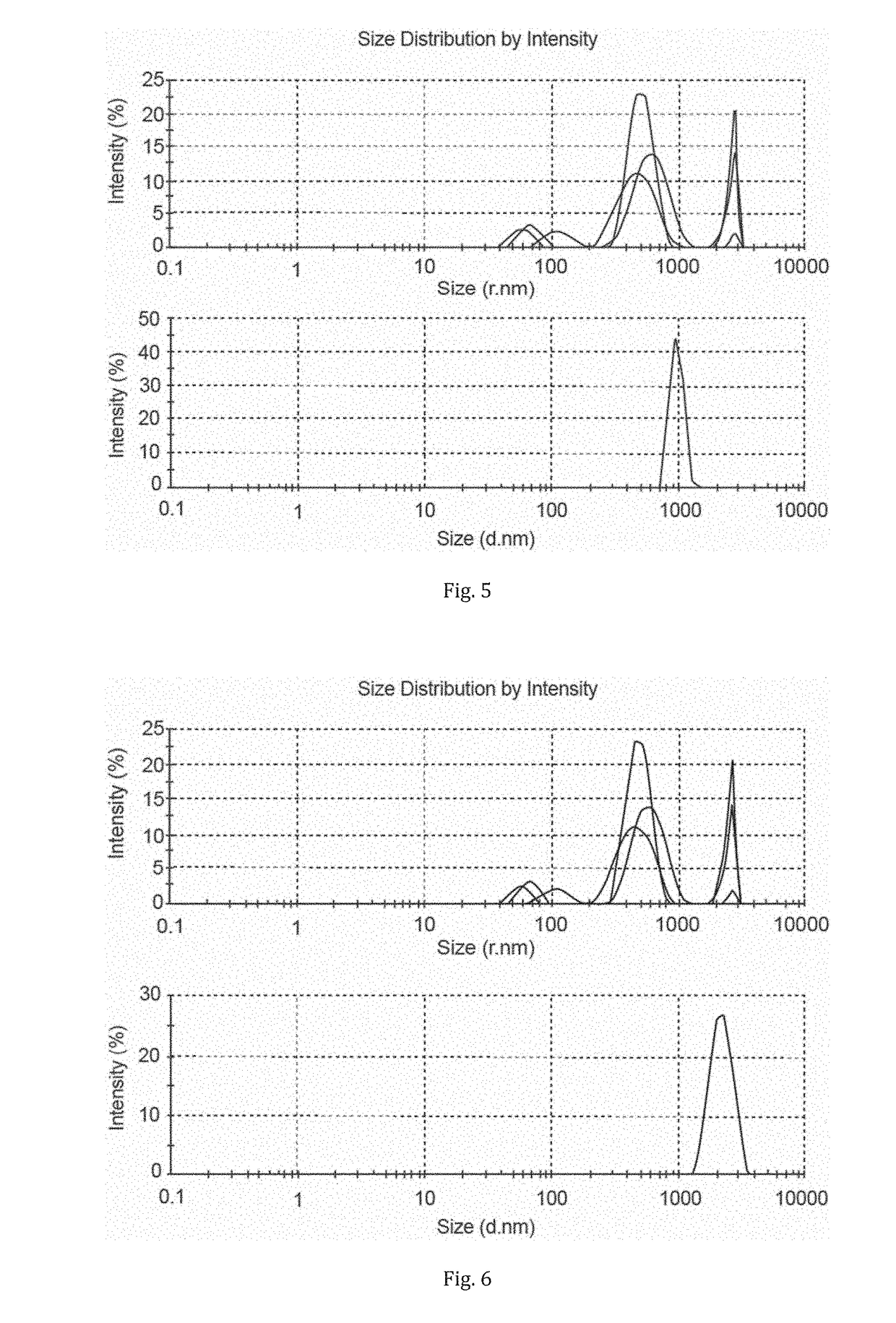

InactiveUS20120071691A1Reduced solvent consumptionReduce wearSolid sorbent liquid separationCarboxylic acid amide separation/purificationRadial chromatographySolvent

A method for separating a mixture of components by simulated moving bed chromatography: (1) feeding the simulated moving bed such that the eluting power of the liquid phase in the second zone is greater than that of the liquid phase in the third zone, trapping the target component inside the second and the third zone; (2) a solvent for dissolving the mixture to be separated, instead of the feeding solution, is fed into the simulated moving bed through the feeding port, and the eluting power of the liquid phase in the second zone is maintained greater than that of the liquid phase in the third zone, thereby both the pre-impurity and the post-impurity are rinsed off completely, and the target component trapped in the second and the third zone is further purified; and (3) the target component trapped in the simulated moving bed is rinsed off the bed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

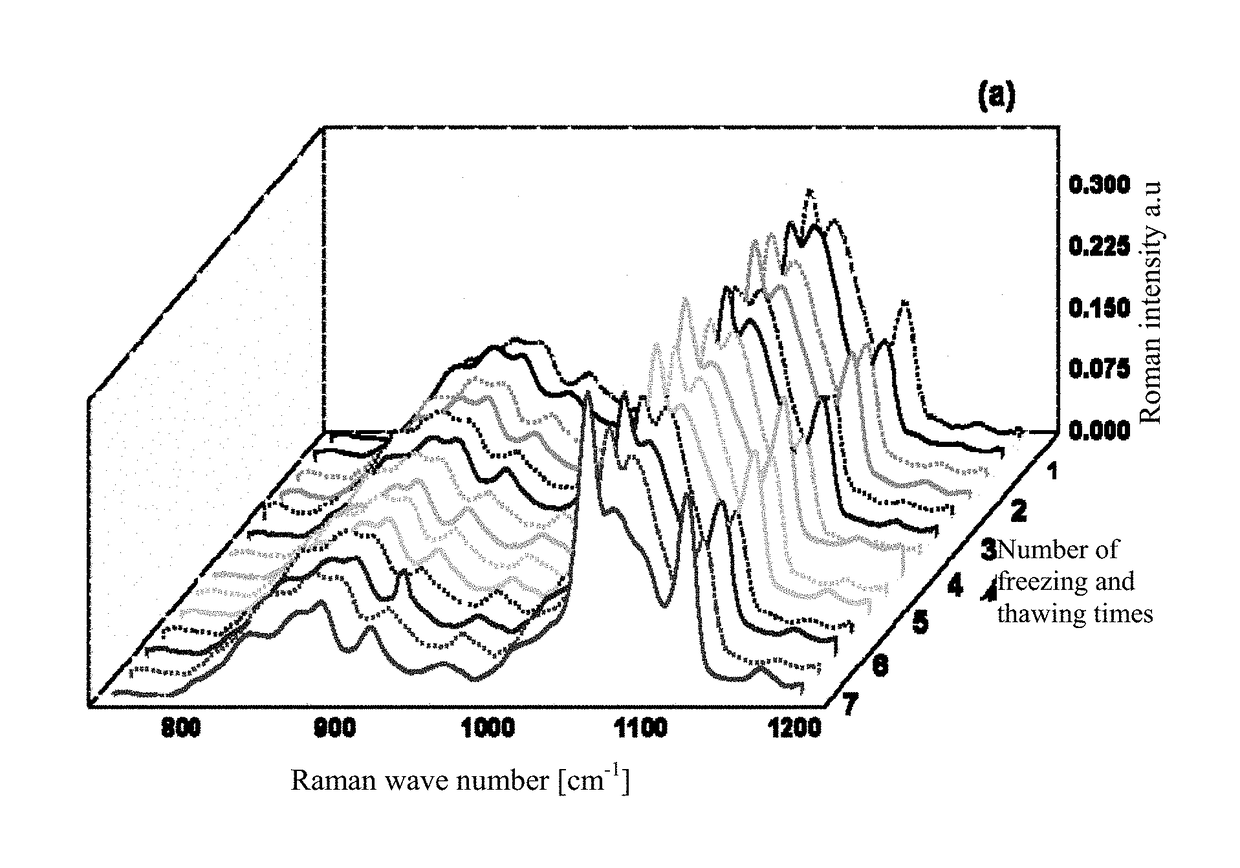

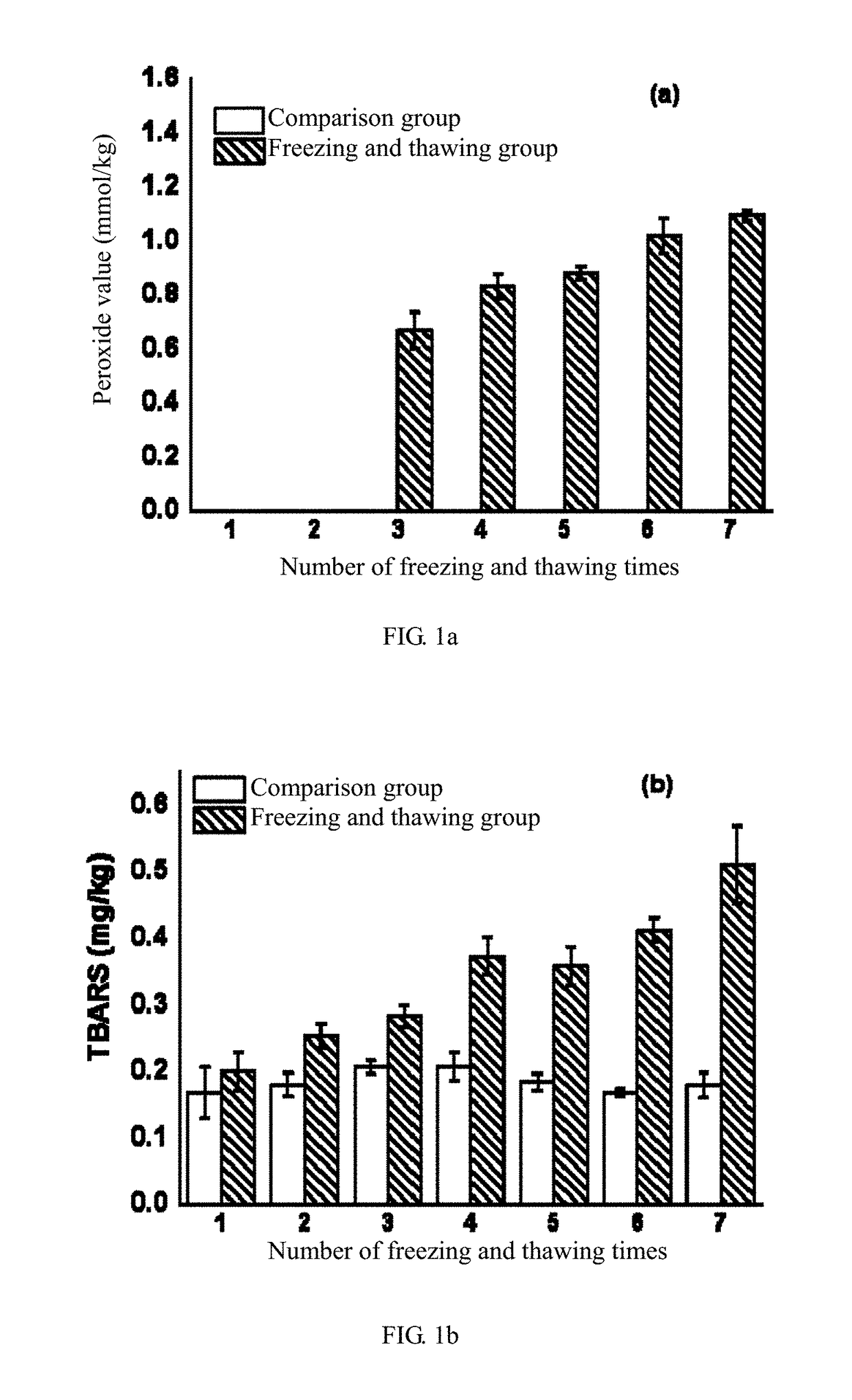

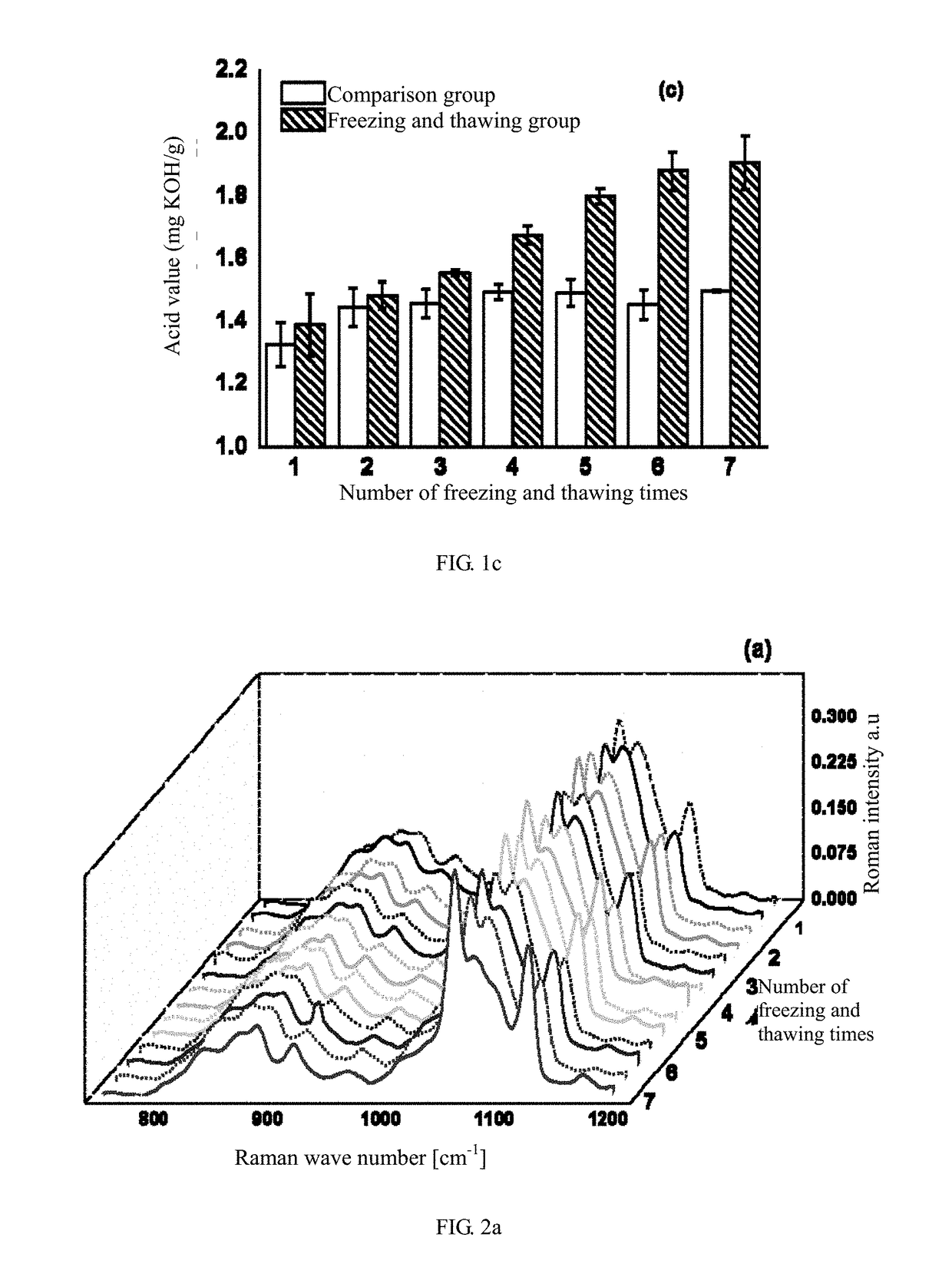

Method for representing quality change process of beef fat during repeated freezing and thawing through Raman spectrum

ActiveUS10126245B1Easy to operateQuick analysisRadiation pyrometryPreparing sample for investigationQuality processFreeze and thaw

A method for representing the quality change process of beef fat during repeated freezing and thawing through a Raman spectrum. The method comprises the steps of (1) setting operating parameters of a laser Raman spectrometer, wherein the operating parameters include the wavelength of exciting light, the laser power and the scanning time; (2) repeatedly freezing and thawing beef, extracting fat in the thawed beef, and then conducting Raman spectrum scanning on the extracted fat; (3) analyzing and processing an obtained original Raman spectrum, so that the quality change process of beef fat during repeated freezing and thawing is represented. The Raman spectrum is used for monitoring the quality change process of beef fat during repeated freezing and thawing, the method is flexible and simple, the analysis speed is high, and the fat quality of beef which is repeatedly frozen and thawed can be represented efficiently and accurately; in addition, analysis solvent consumption is low, and the detection cost is low.

Owner:JIANGNAN UNIV

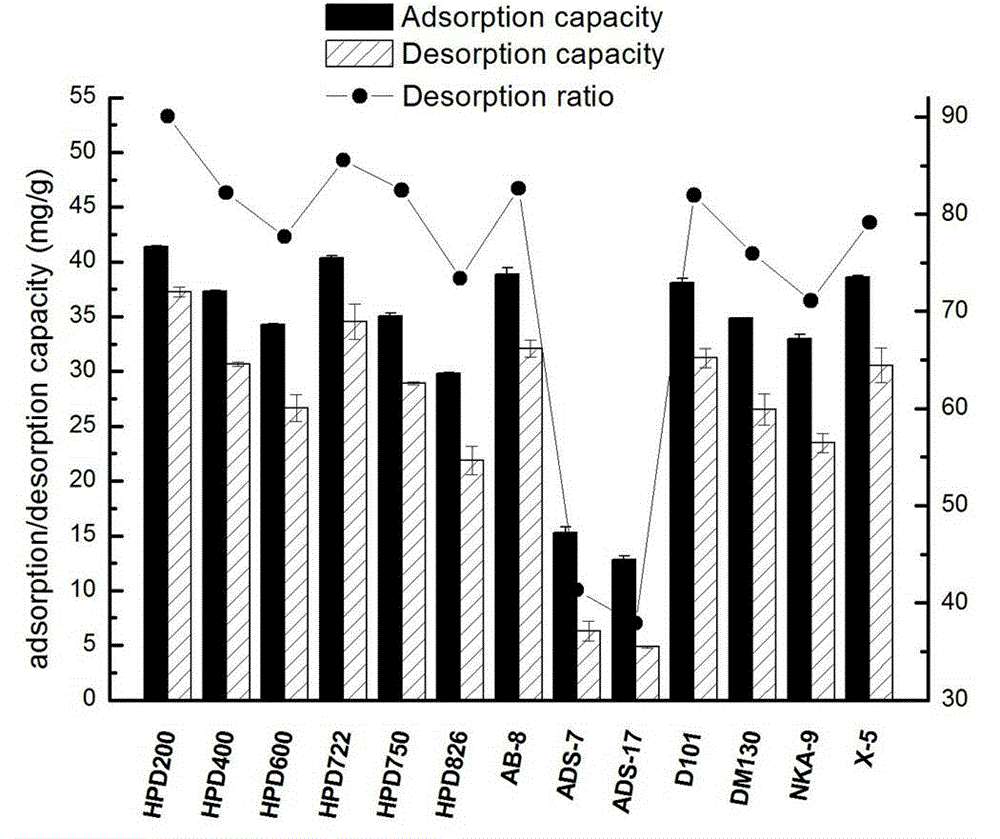

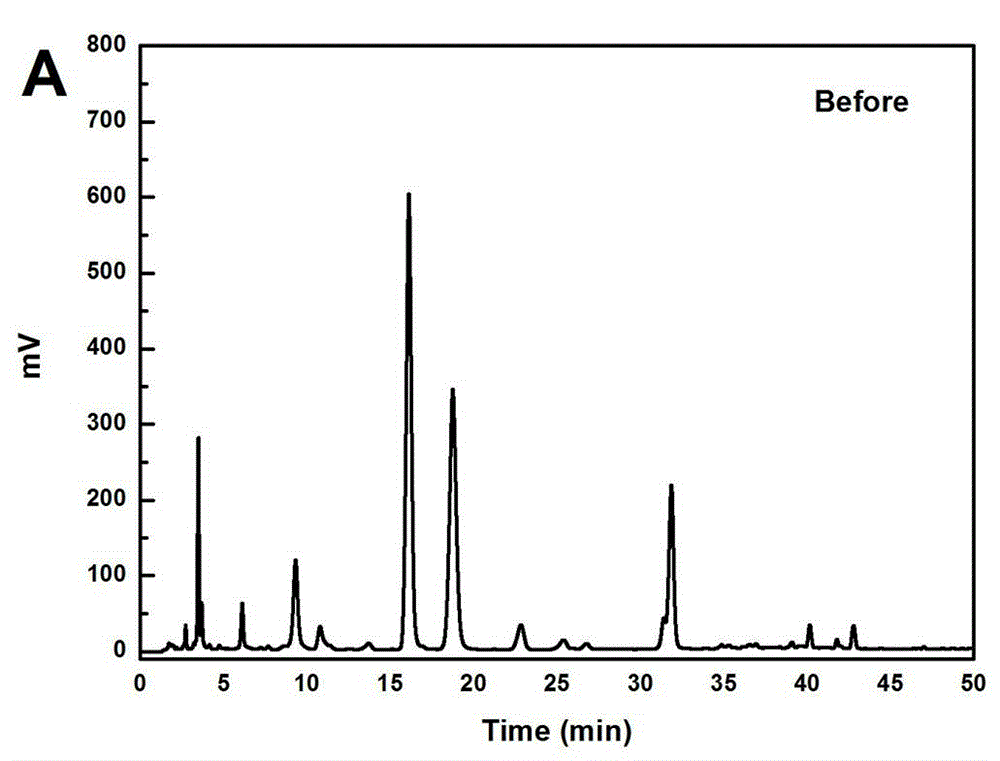

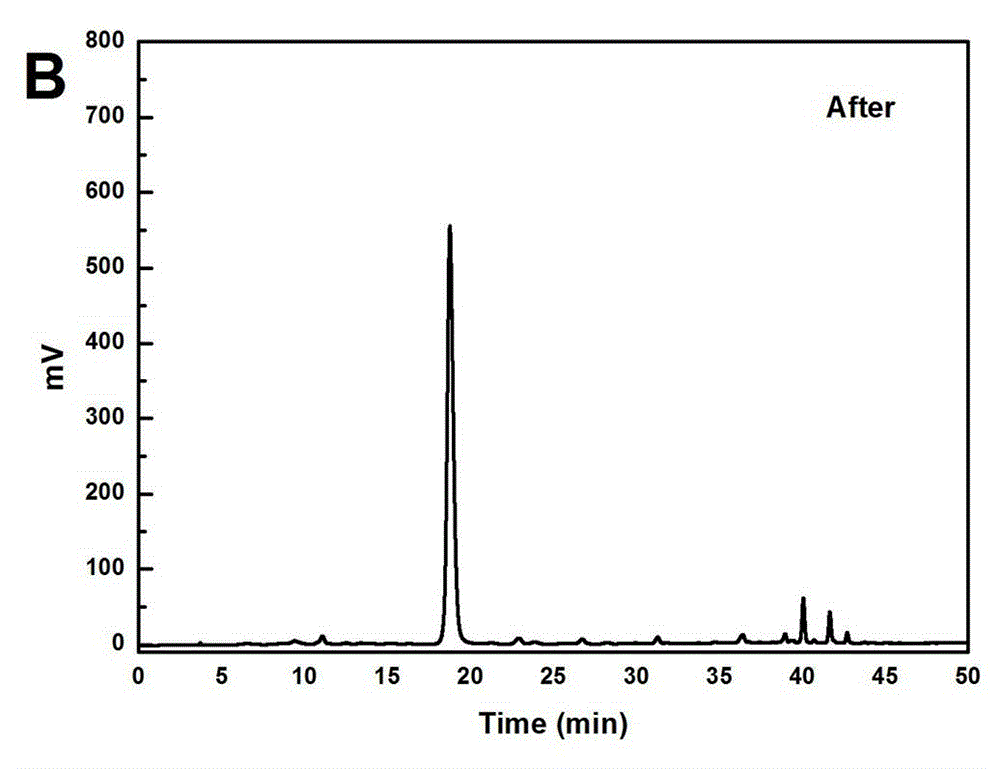

Method for preparing high-purity EGCG from hydrogen-bonded macroporous resin

InactiveCN104447668AIncrease surface areaUnique adsorptionOrganic chemistryGreen teasAqueous ethanol

The invention provides a method for preparing high-purity EGCG from a hydrogen-bonded macroporous resin, aiming to solve the problems that toxic chemical reagents are adopted by the existing methods for preparing EGCG so that the safety of medicines can not be guaranteed, and the existing methods for preparing EGCG are not suitable for large-scale production. The method is characterized by comprising the following steps: (1) weighing green tea, adding an appropriate amount of distilled water, heating the green tea to the temperature of 60-80 DEG C, and extracting to obtain green-tea extract; (2) adsorbing the green-tea extract with the hydrogen-bonded macroporous adsorption resin directly, eluting with 10-20% ethanol water to remove impurities, further eluting with 30% ethanol water, and collecting eluate; and (3) concentrating the eluate, freeze-drying, and recrystallizing to obtain the finished product. The macroporous resin can be recycled, the method is simple in technical route, is low in cost and is high in separation efficiency, is environment-friendly and is suitable for the industrial production of EGCG.

Owner:中国医科大学

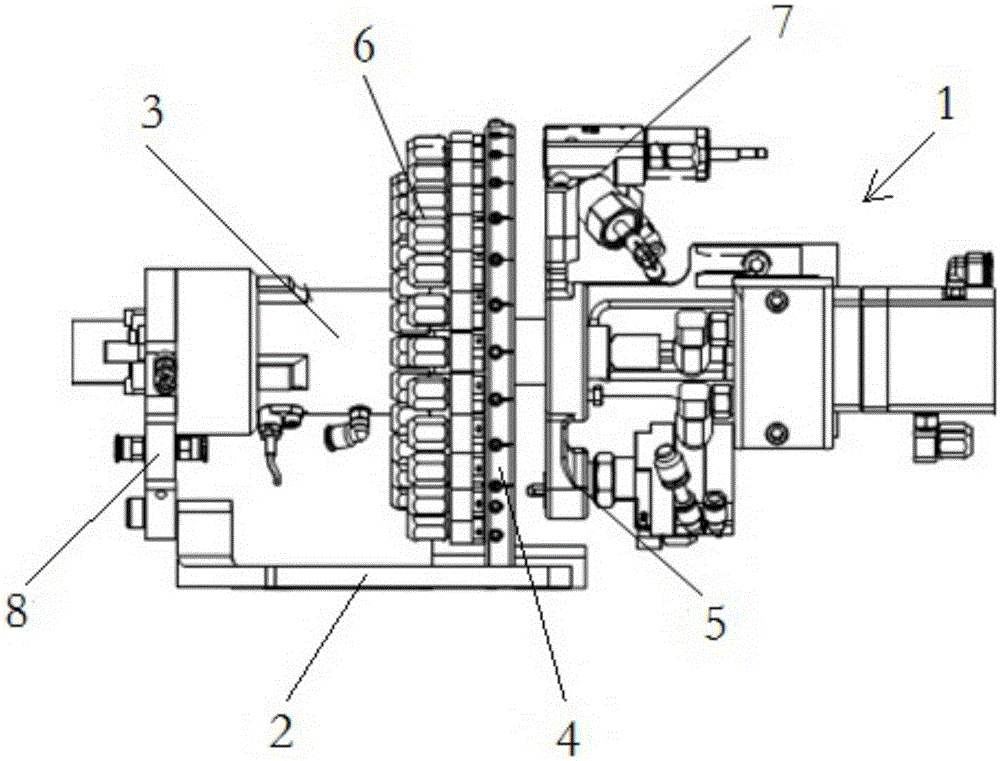

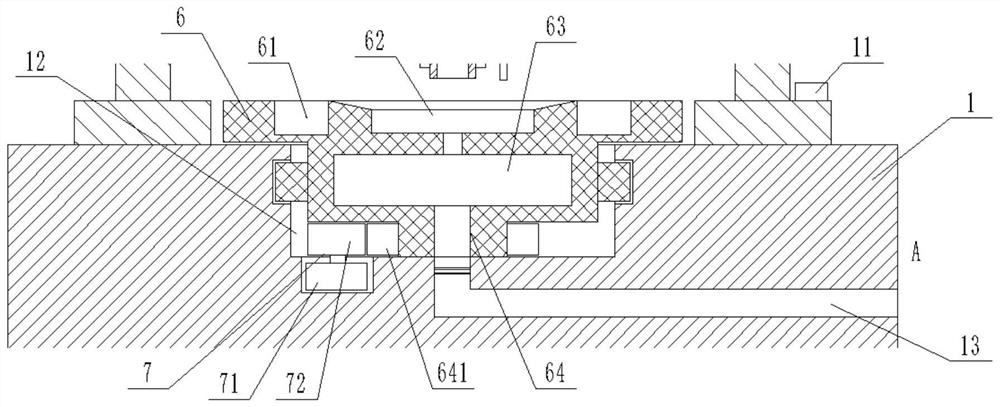

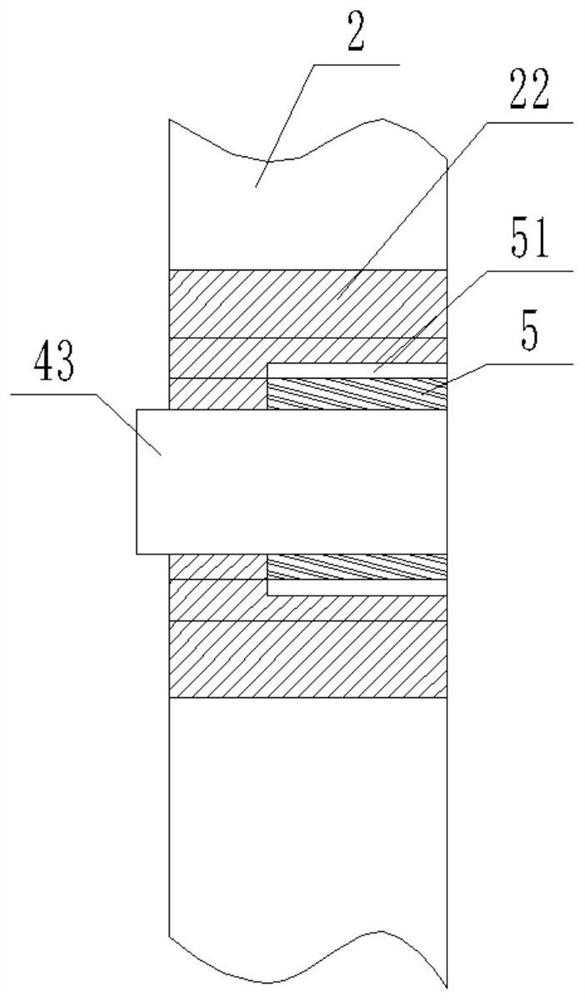

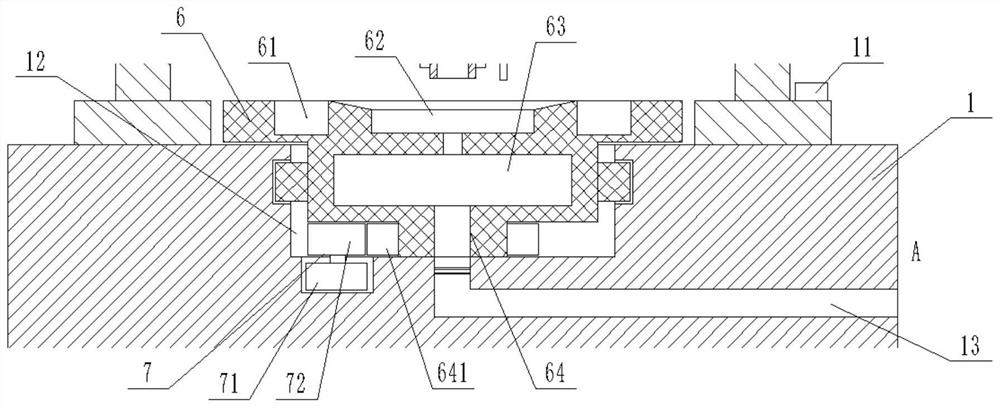

Novel color changing valve structure and work method thereof

ActiveCN105709963AShorten color change timeReduced solvent consumptionSpraying apparatusSolventColor changes

The invention discloses a novel color changing valve structure and a work method thereof. The novel color changing valve structure comprises a base, a spindle, a wheel disc and a rotating disc; the spindle is horizontally arranged above the base and penetrates the wheel disc, and the rotating disc is rotatably connected with the spindle; the wheel disc is provided with a plurality of coating input openings, and a coat output opening is formed in the rotating disc; and the process that in the color changing process of a traditional color changing valve, a color changing valve main pipeline needs to be cleaned is omitted. According to a color changing valve, the color changing time can be shortened, and meanwhile solvent consumption can be further saved.

Owner:SHANGHAI FANUC ROBOTICS

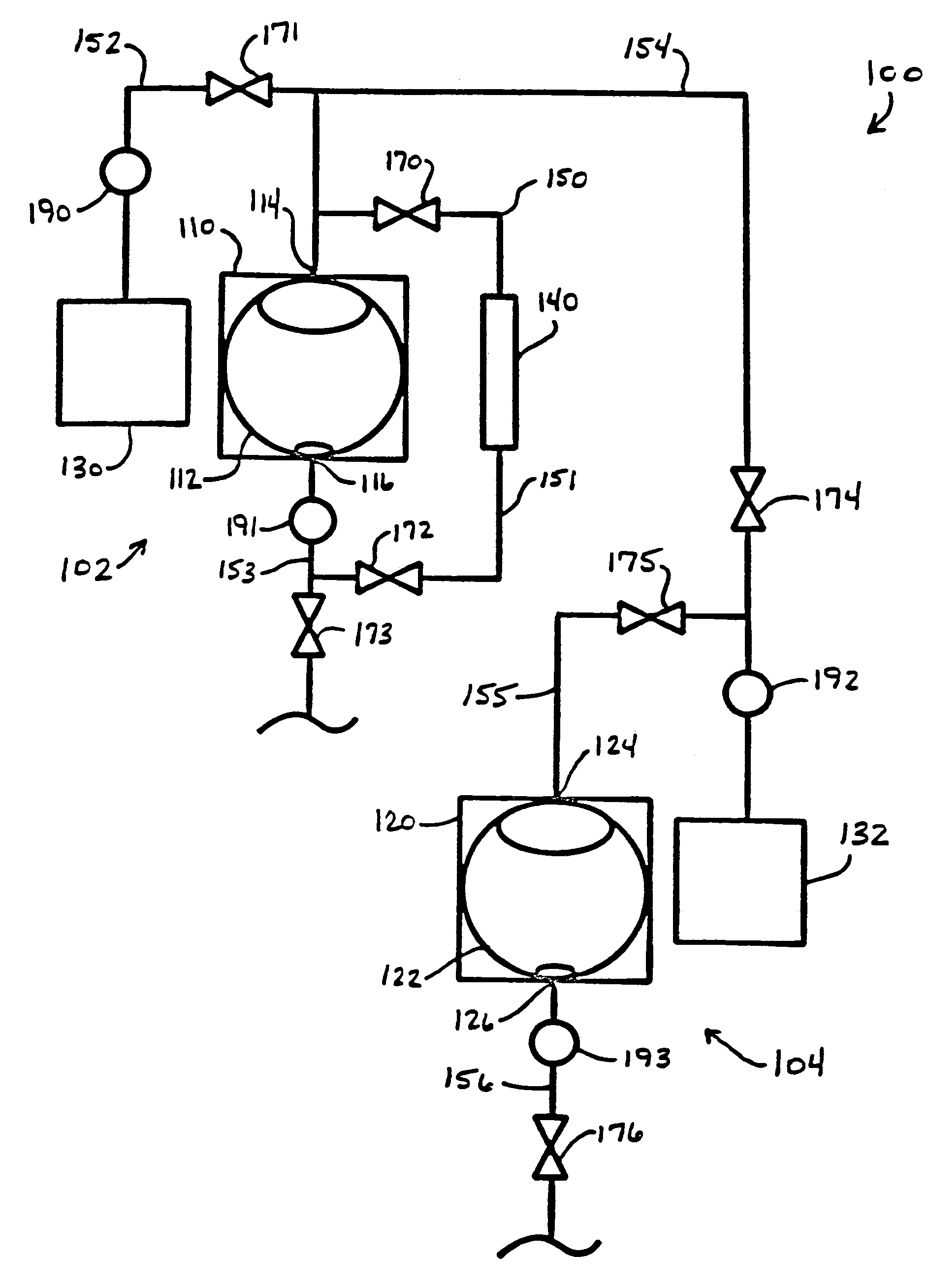

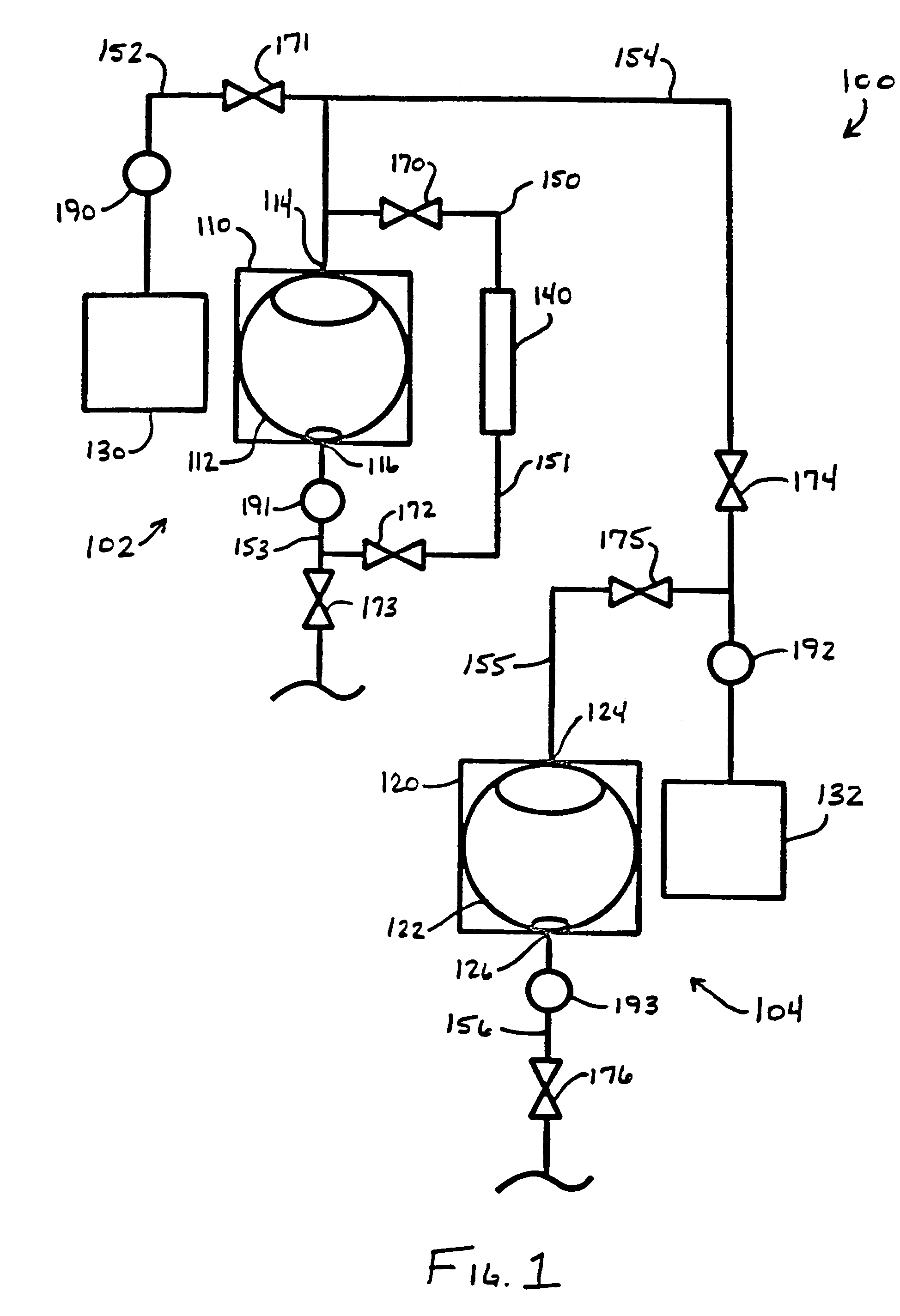

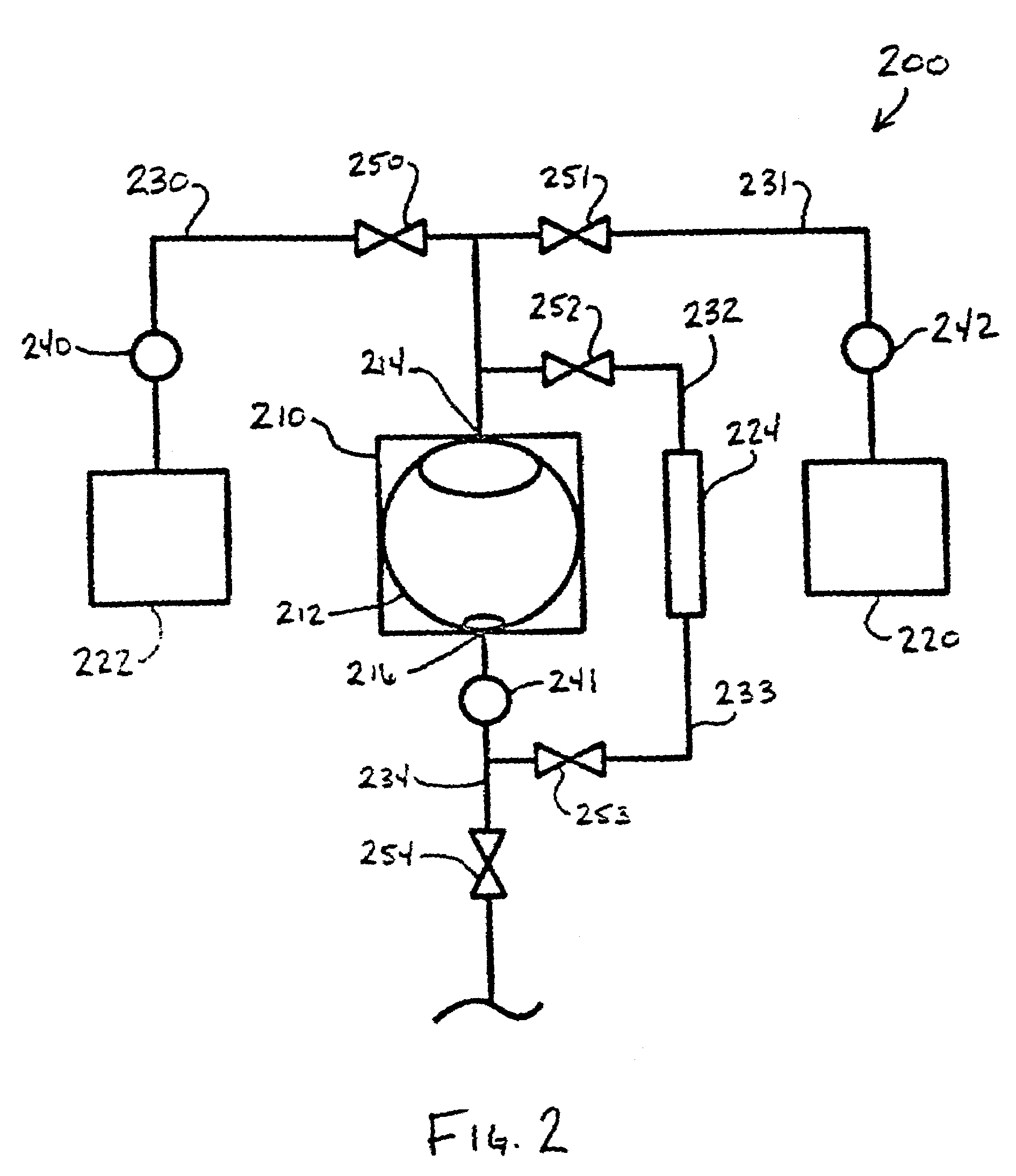

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7435265B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

Monolithic silicone and method of separation, purification and concentration therewith

ActiveUS9285300B2Increase flexibilityHigh porositySilicon organic compoundsOther chemical processesSolventPolymer chemistry

The present invention provides a monolithic silicone in the form of an aerogel or a xerogel having flexibility and capable of dissolving molecules of a substance. This silicone monolithic body having continuous through passages is synthesized by copolymerizing starting materials of both a bifunctional alkoxysilane and a trifunctional alkoxysilane or tri- or higher functional alkoxysilanes through a sol-gel reaction for forming a Si—O network while causing phase separation.

Owner:KYOTO UNIV +1

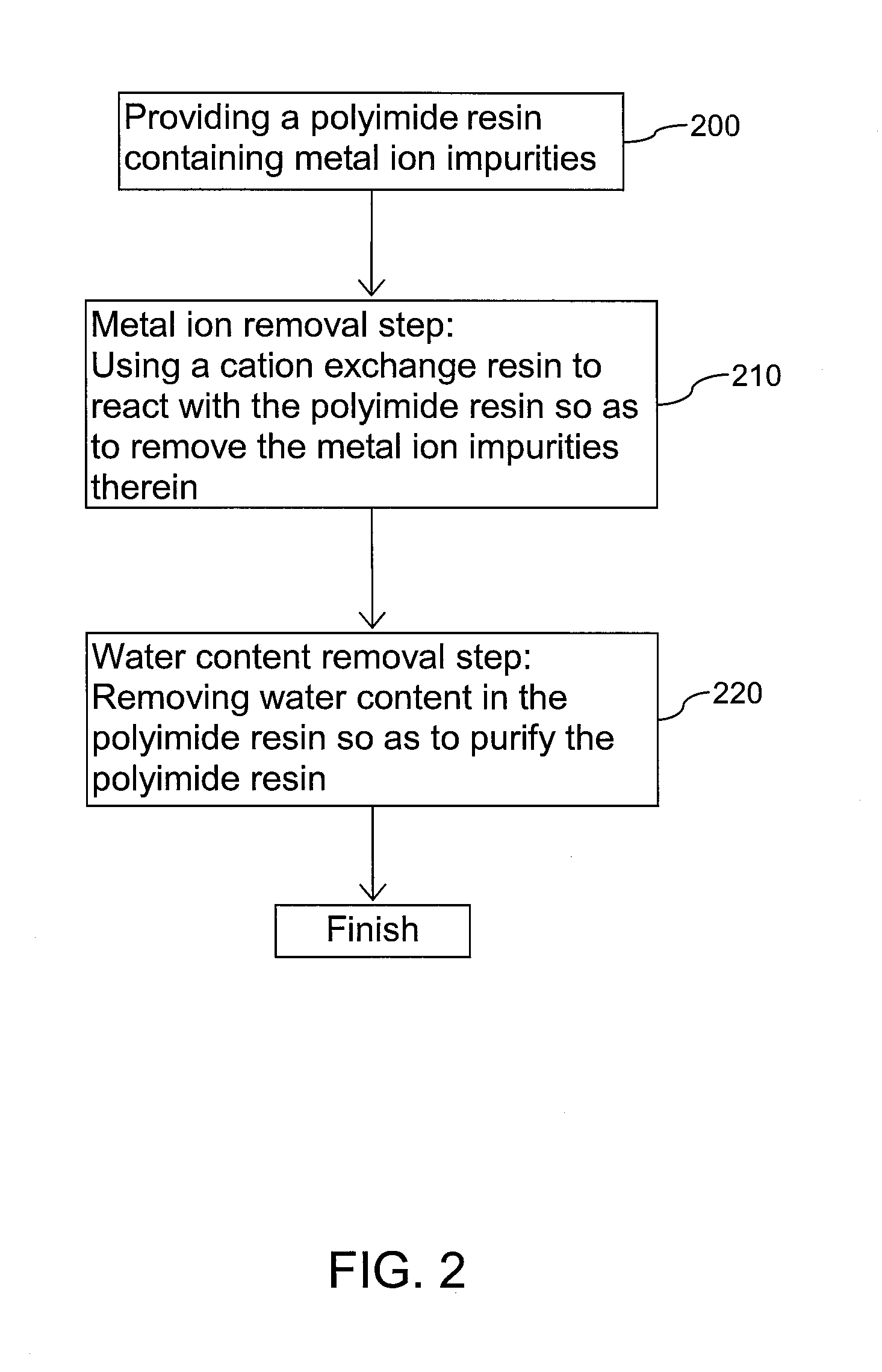

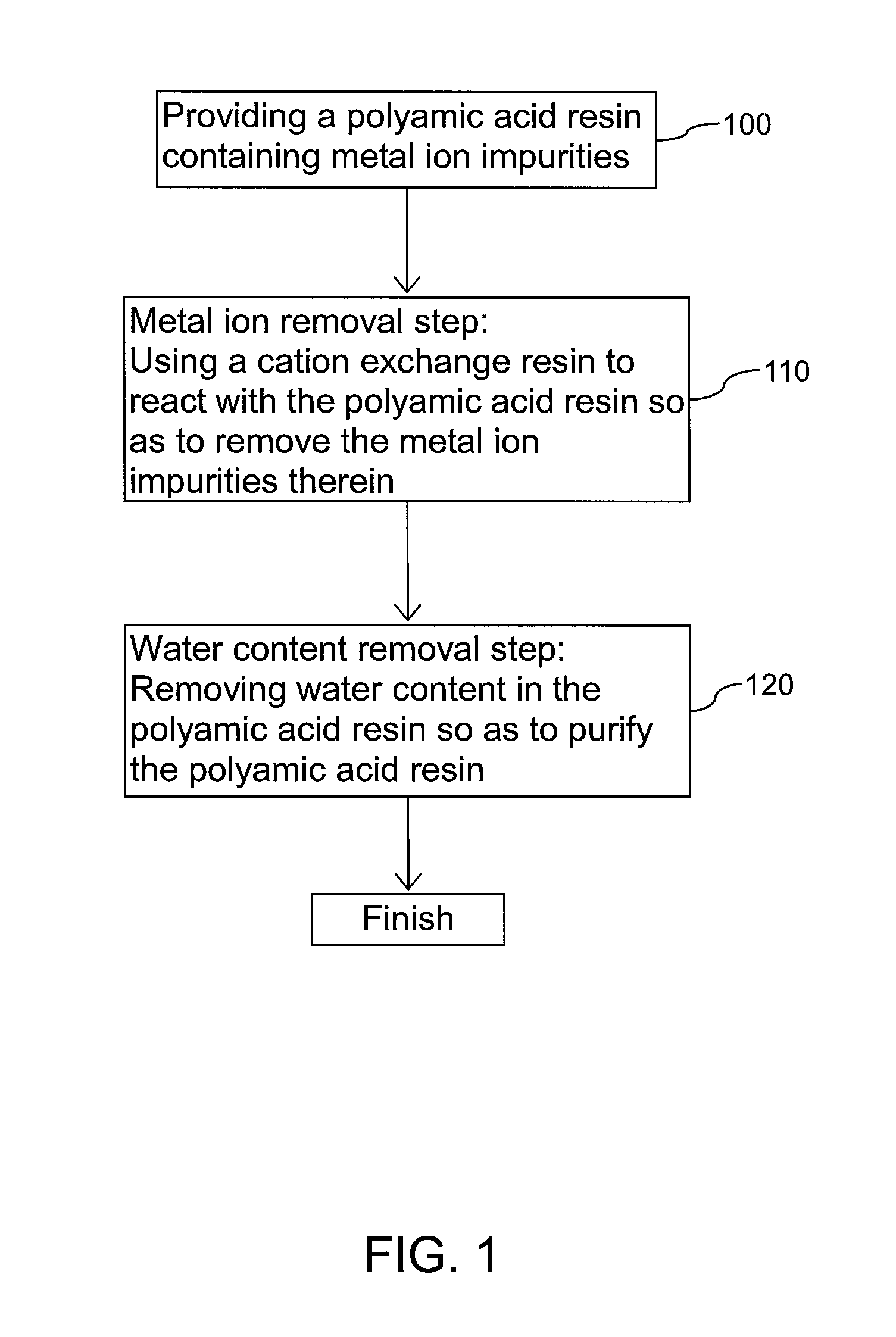

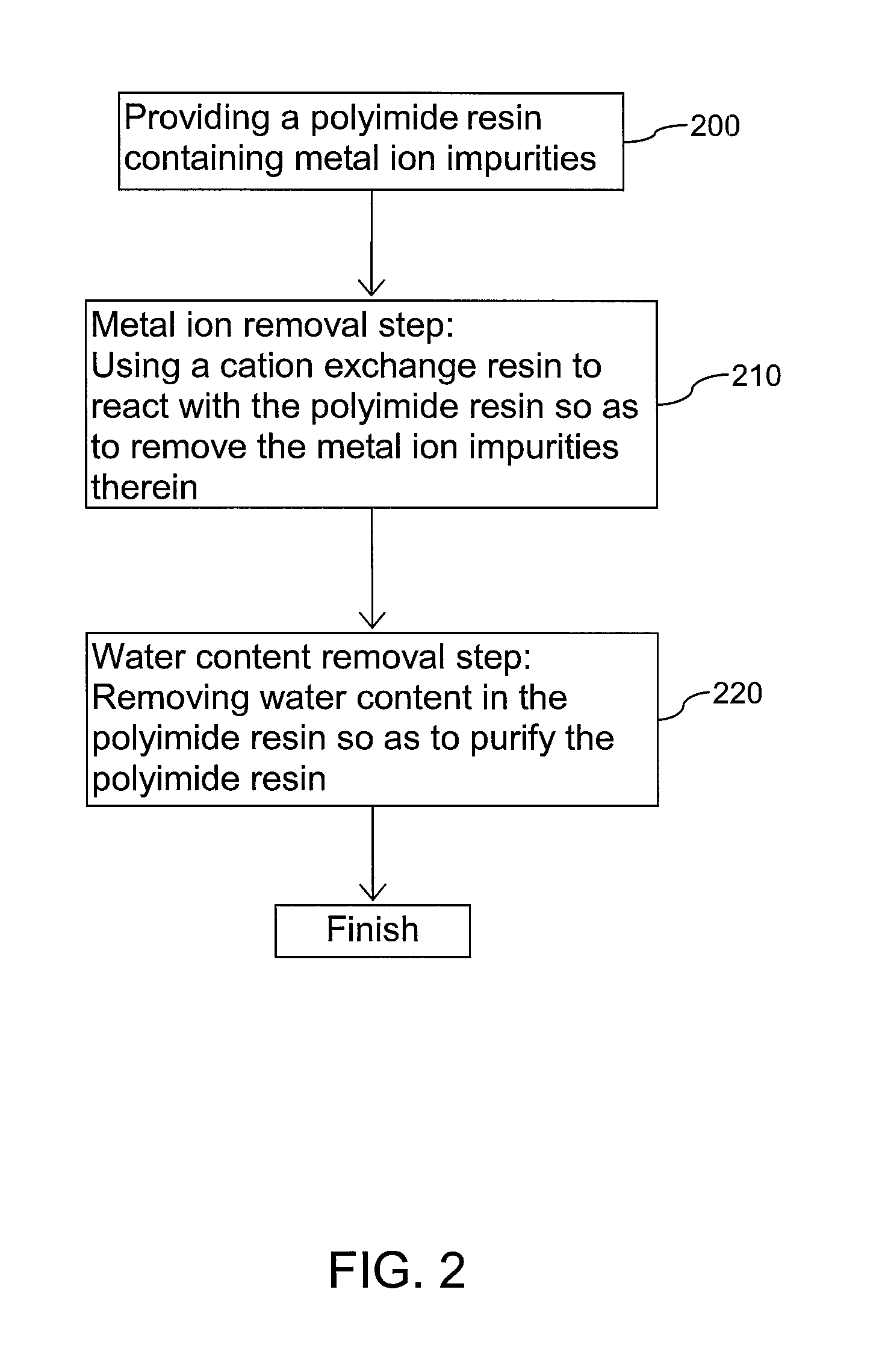

Purification method of polyamic acid resin and polyimide resin

ActiveUS20110160423A1Reduce consumptionEffectively removeProcess efficiency improvementWater contentPolymer chemistry

Purification methods of polyamic acid resin and polyimide resin are provided. The purification methods of polyamic acid resin or polyimide resin includes providing a polyamic acid resin or a polyimide resin containing metal ion impurities. Thereafter, a cation exchange resin is used to react with the polyamic acid resin or the polyimide resin in order to remove the metal ion impurities therein, and a water content in the polyamic acid resin or the polyimide resin is removed to purify the polyamic acid resin or polyimide resin.

Owner:DAXIN MATERIALS

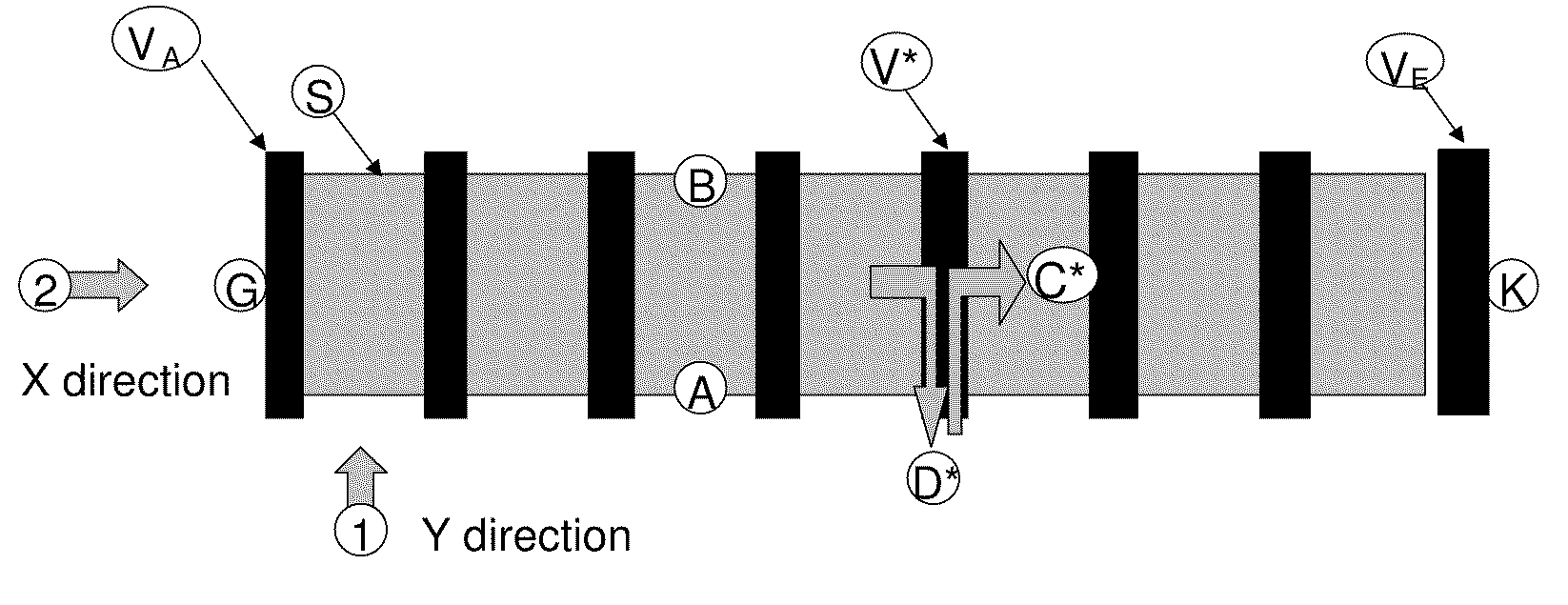

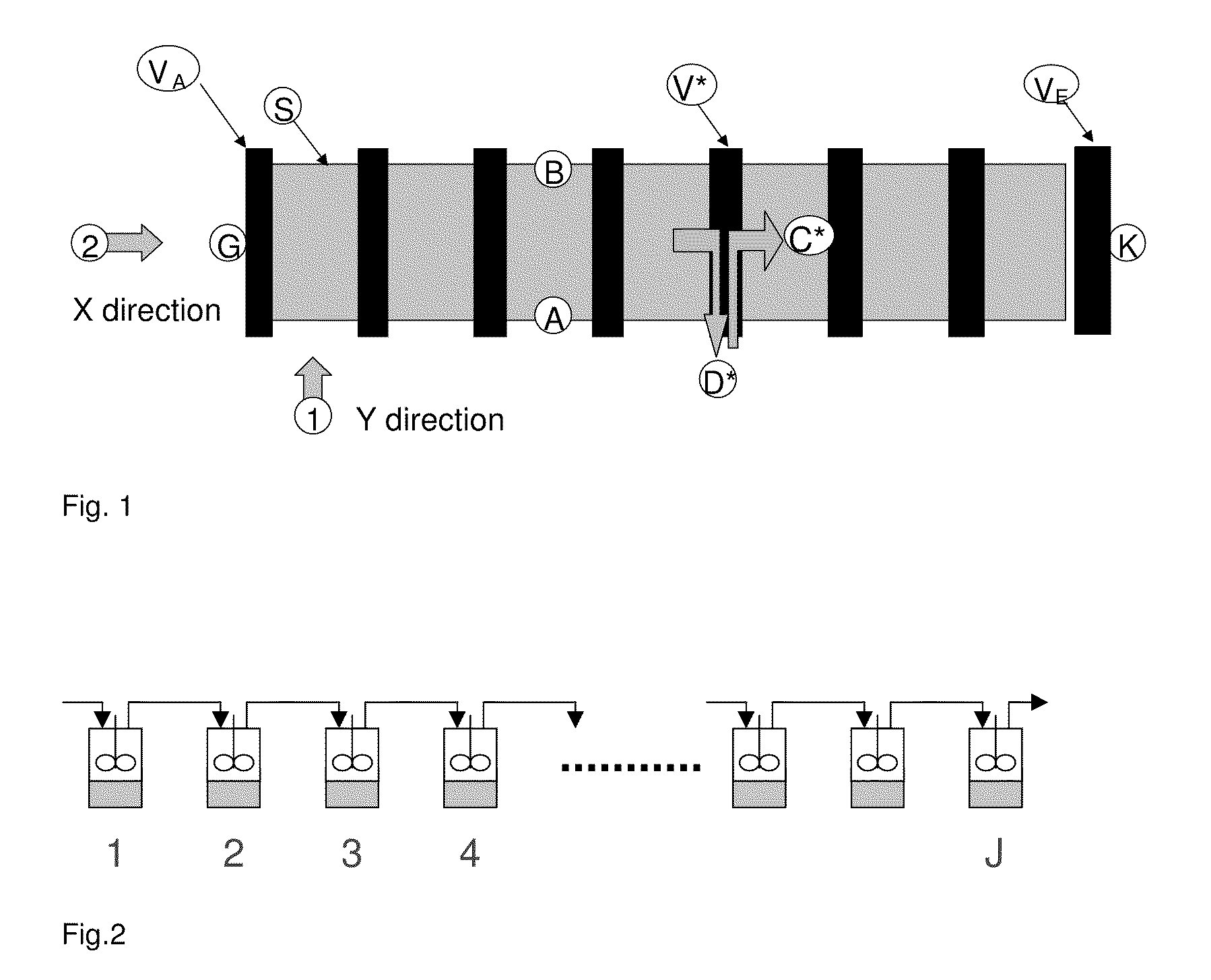

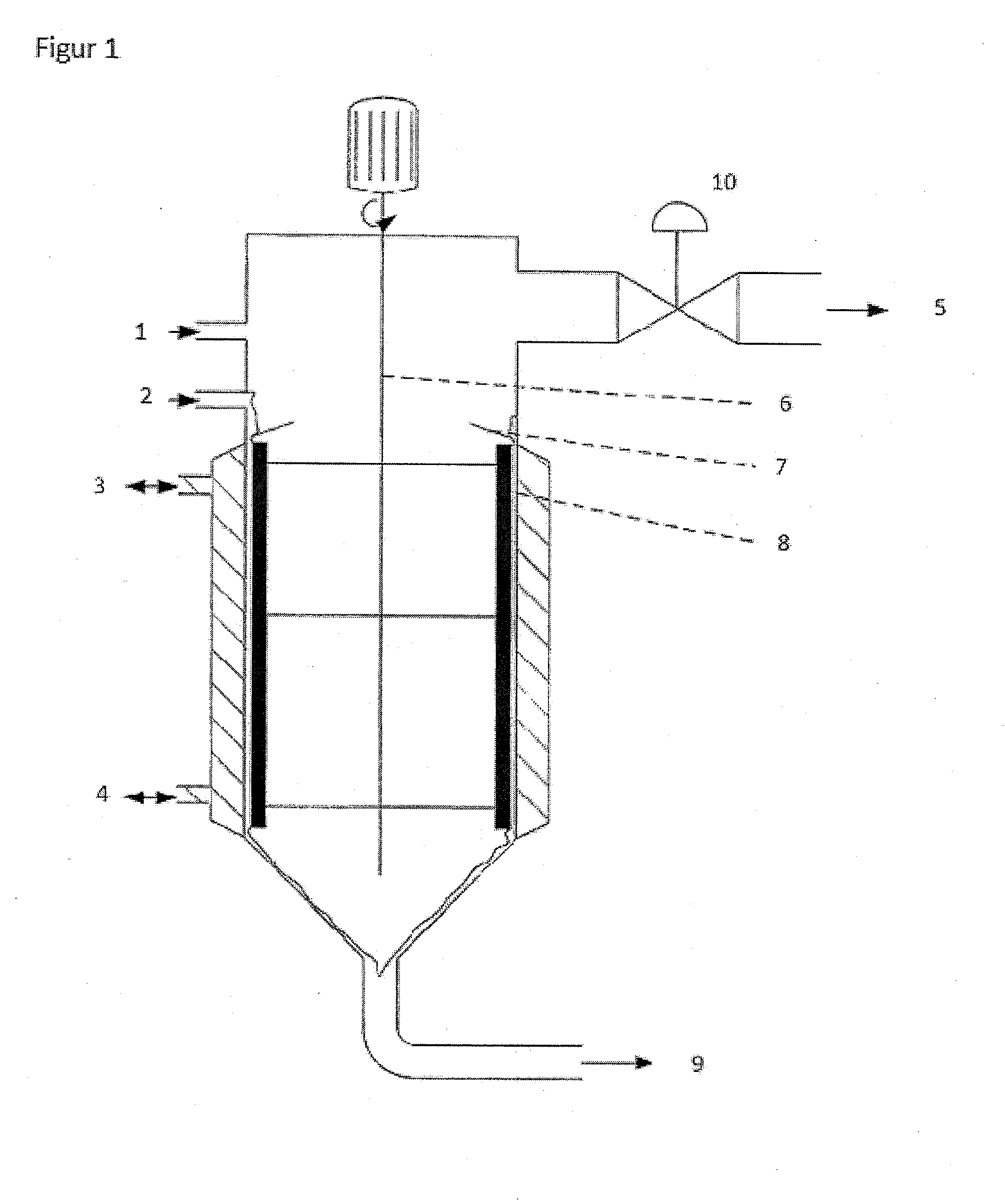

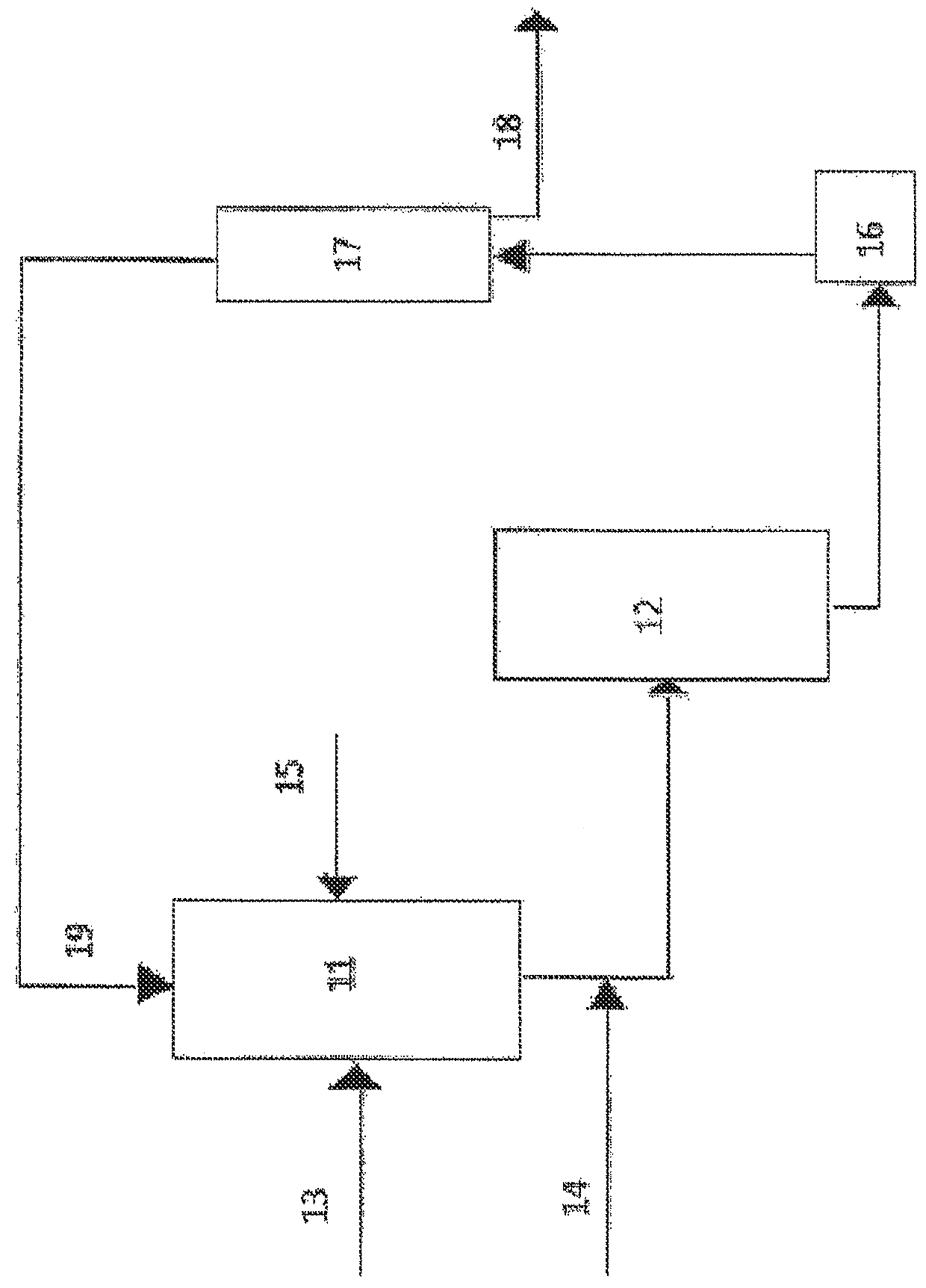

Semi-continuous chromatographic method and corresponding device for the separation of binary and multi-component mixtures

InactiveUS7749390B2Improve productivityReduced solvent consumptionIon-exchange process apparatusComponent separationChemistry

Owner:BAYER INTELLECTUAL PROPERTY GMBH

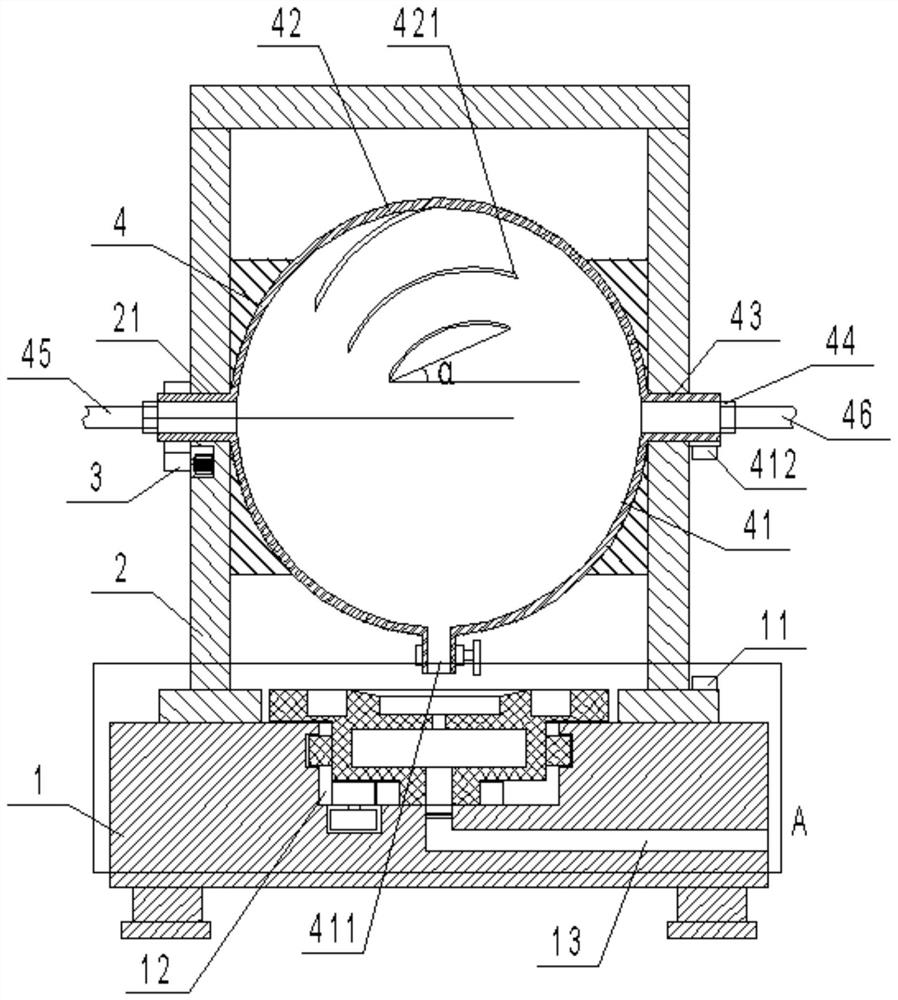

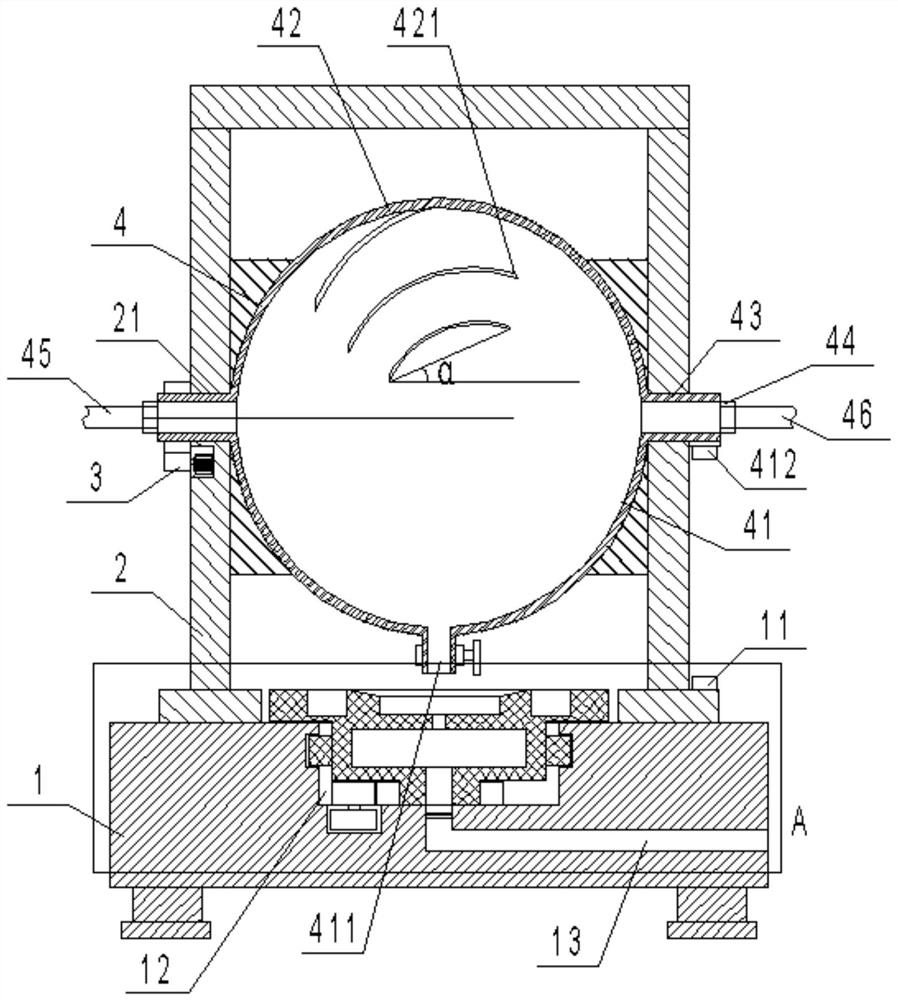

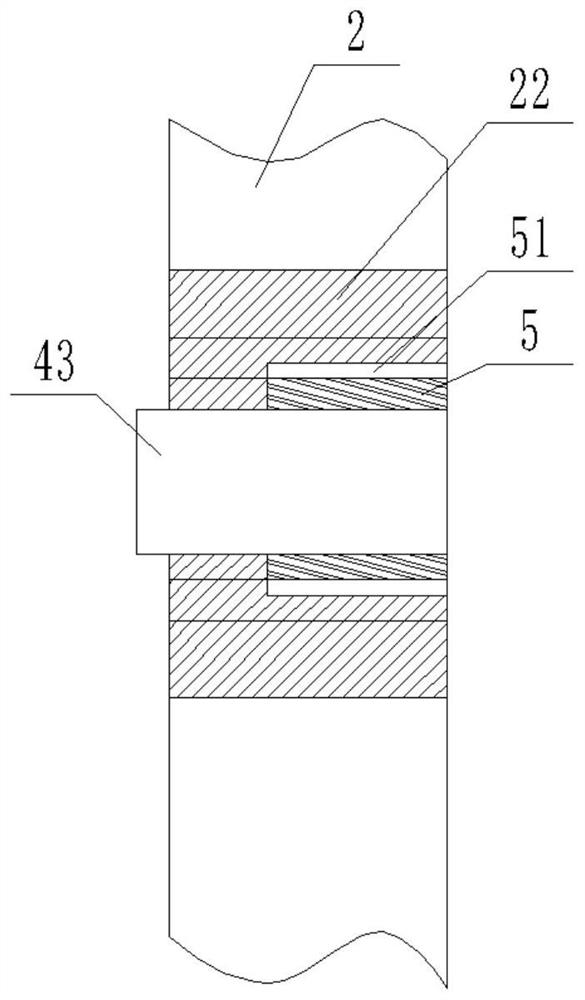

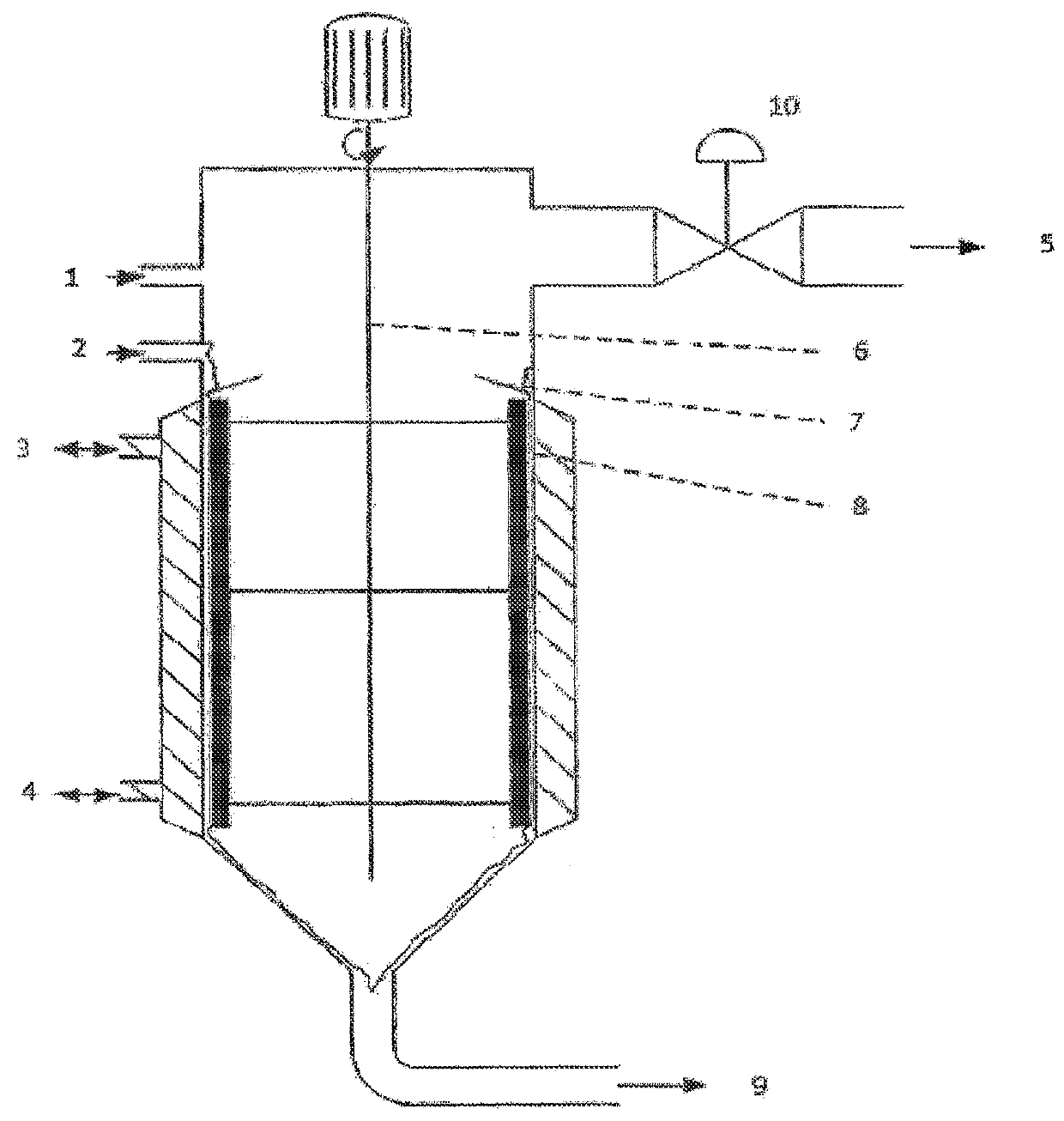

Chemical experiment extraction device

ActiveCN112516623AWell mixedImprove mixing efficiencyLiquid solutions solvent extractionStructural engineeringBottle

The present invention provides a chemical experiment extraction device, which comprises: a base with two ends vertically connected to fixed brackets, driving parts arranged on the fixed brackets and used for providing power, and an extraction reaction bottle with two ends rotatably arranged on the two fixed brackets; the driving parts can drive the extraction reaction bottle to rotate; the extraction reaction bottle comprises a first bottle body and a second bottle body, a liquid drainage port is formed in the protruded end part of the first bottle body, a plurality of inclined baffle plates are arranged on the inner wall of the second bottle body, the first bottle body and the second bottle body are combined to form an extraction chamber; and a photoelectric sensor is arranged at the end,close to the corresponding fixed bracket, of the first bottle body, a receiver is arranged on the base, and the receiver is arranged on the lower side of the photoelectric sensor and corresponds to the photoelectric sensor in position. According to the device, the extraction reaction bottle rotates in the vertical direction, so that multi-phase extraction liquid can be fully mixed, liquid mixingcan be further promoted through the inclined baffle plates on the inner wall of the extraction reaction bottle, and the mixing efficiency is improved.

Owner:SHAANXI SCI TECH UNIV

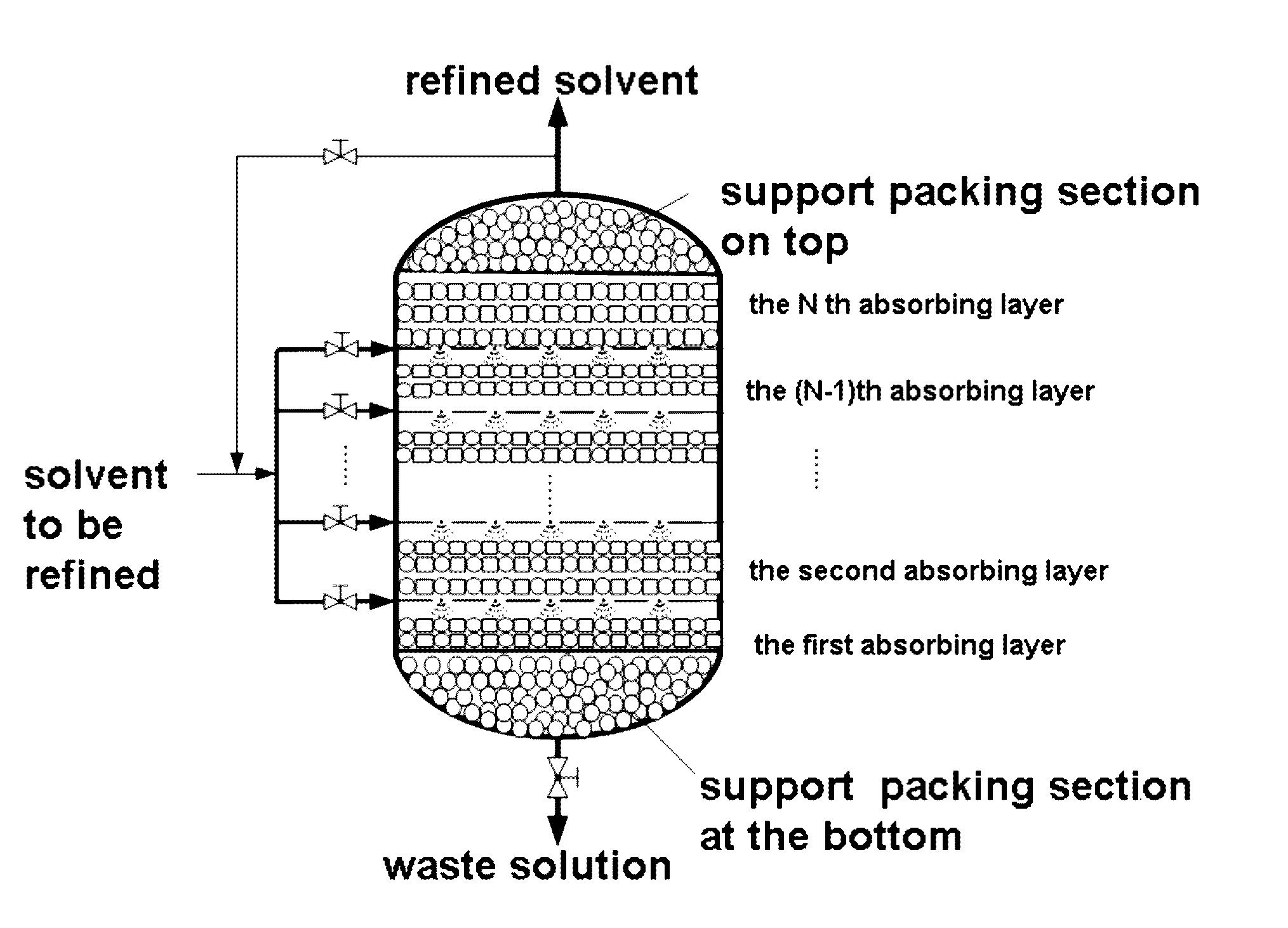

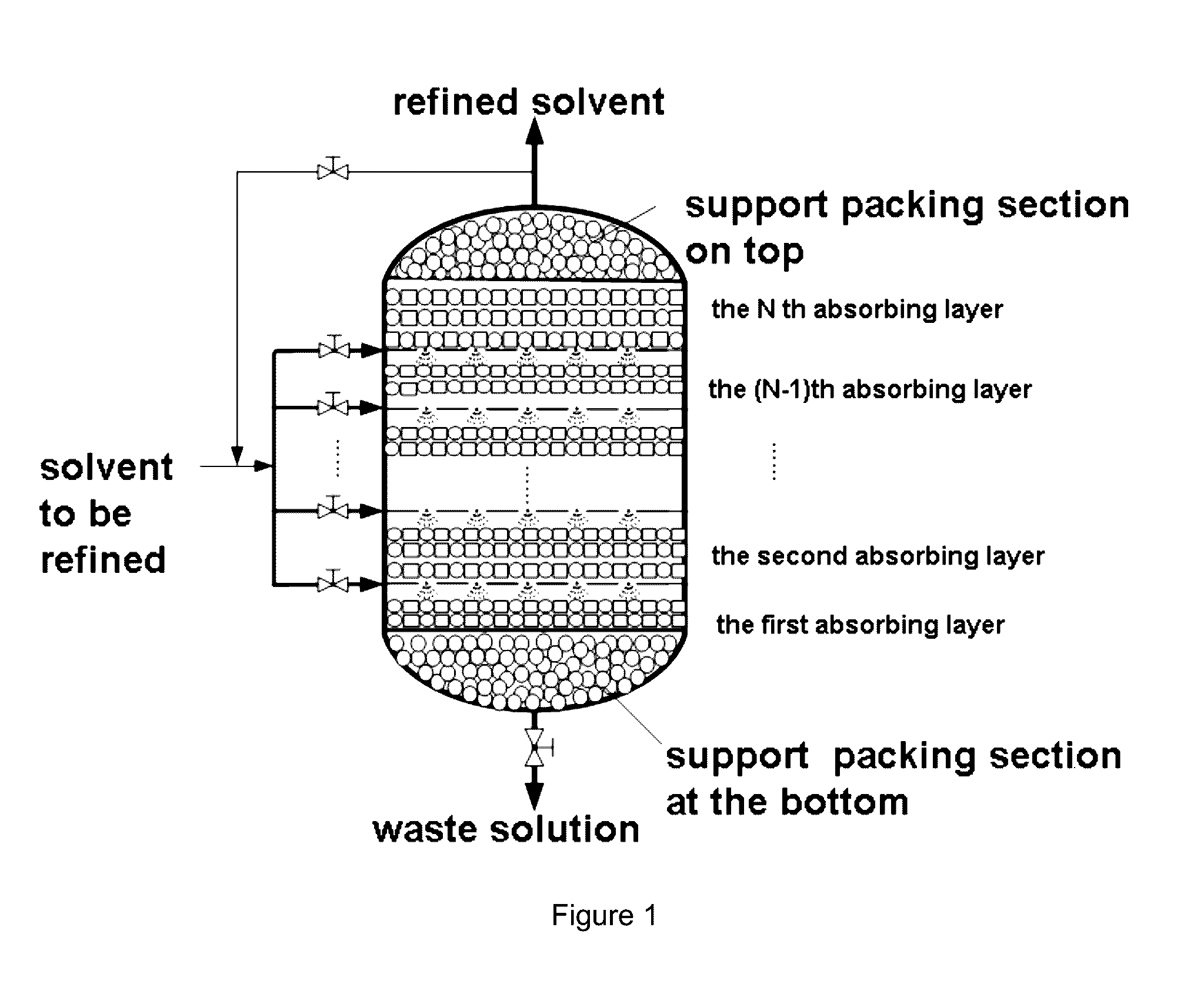

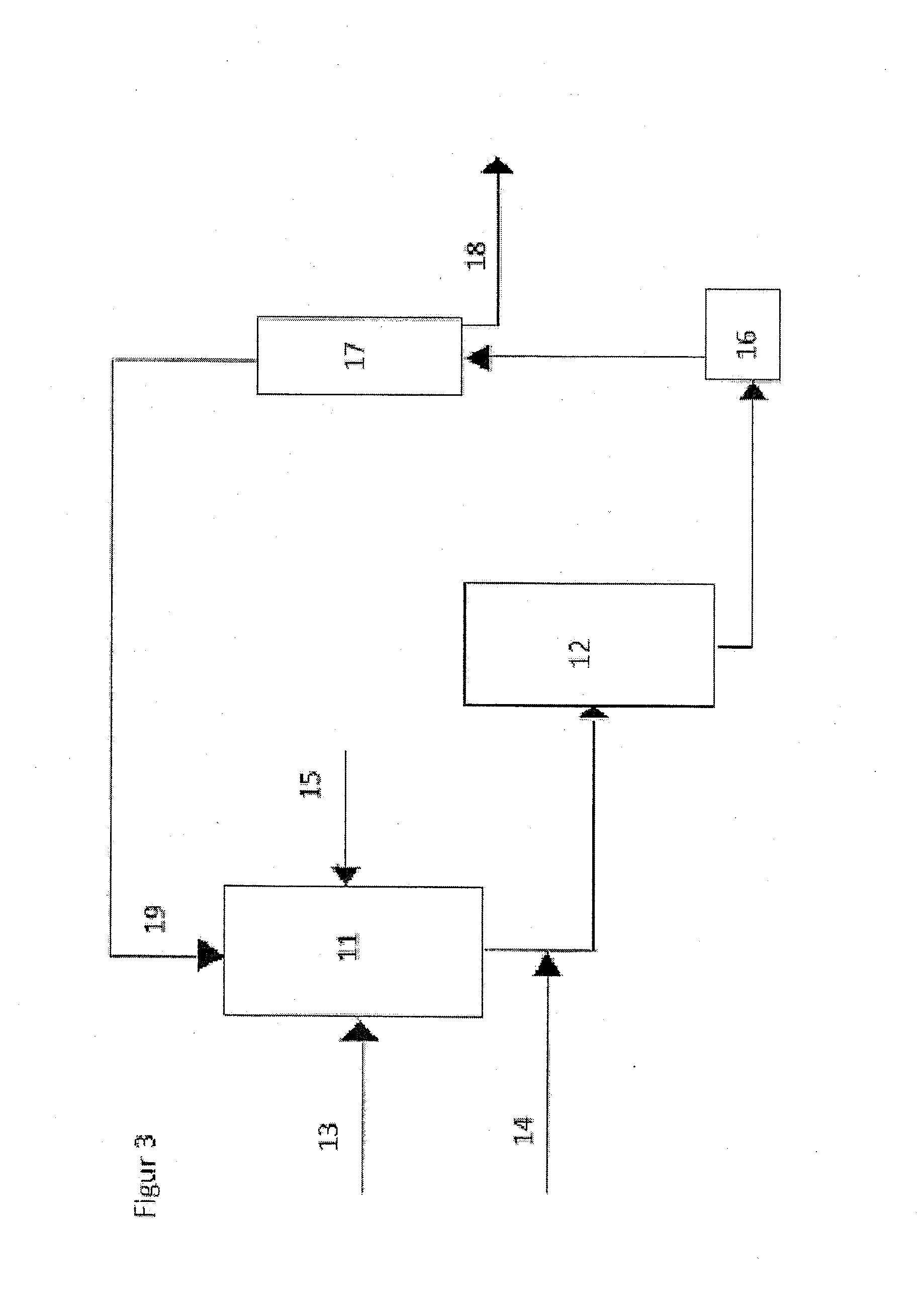

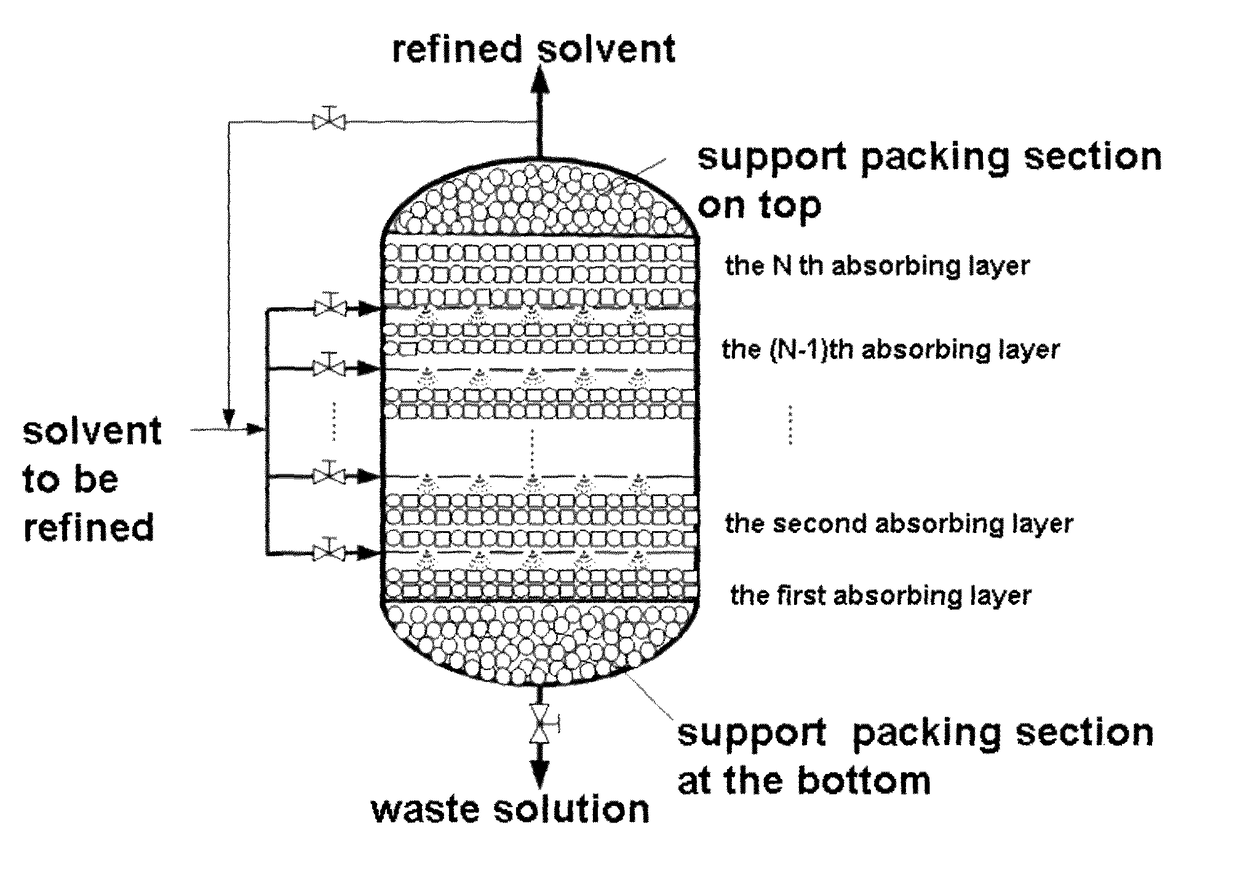

Solvent refining method for isocyanate prepared by phosgene method and devices used in same

ActiveUS20170022152A1Simple processLow production costOrganic compound preparationSolid sorbent liquid separationPresent methodDesiccant

A solvent refining method for isocyanate prepared by the phosgene method and multistage absorbing towers used in same. Solvent to be refined which contains water, iron, and / or phosgene, hydrogen chloride and other materials with color is dealt by the present method and multistage absorbing towers, which can effectively prevent a drying agent from absorbing water and hardening, partial overheating in the tower and generating channeling. Meanwhile, the pressure drop is effectively lowered. In addition, the content of water is ≦50 ppm, the content of iron is ≦5 ppm, the content of phosgene and hydrogen chloride is ≦20 ppm, Pt—Co chroma is ≦20 in the refined solvent. Therefore, the refined solvent can be used as the solvent for preparing isocyanate in the phosgene method and remarkably improve an L color of isocyanate.

Owner:WANHUA CHEM GRP CO LTD

Gas-liquid separator and inkjet recording apparatus using the same

ActiveUS9308738B2Compact structureFree set-up directivityLiquid degasificationOther printing apparatusVapor–liquid separatorSuction force

Owner:HITACHI IND EQUIP SYST CO LTD

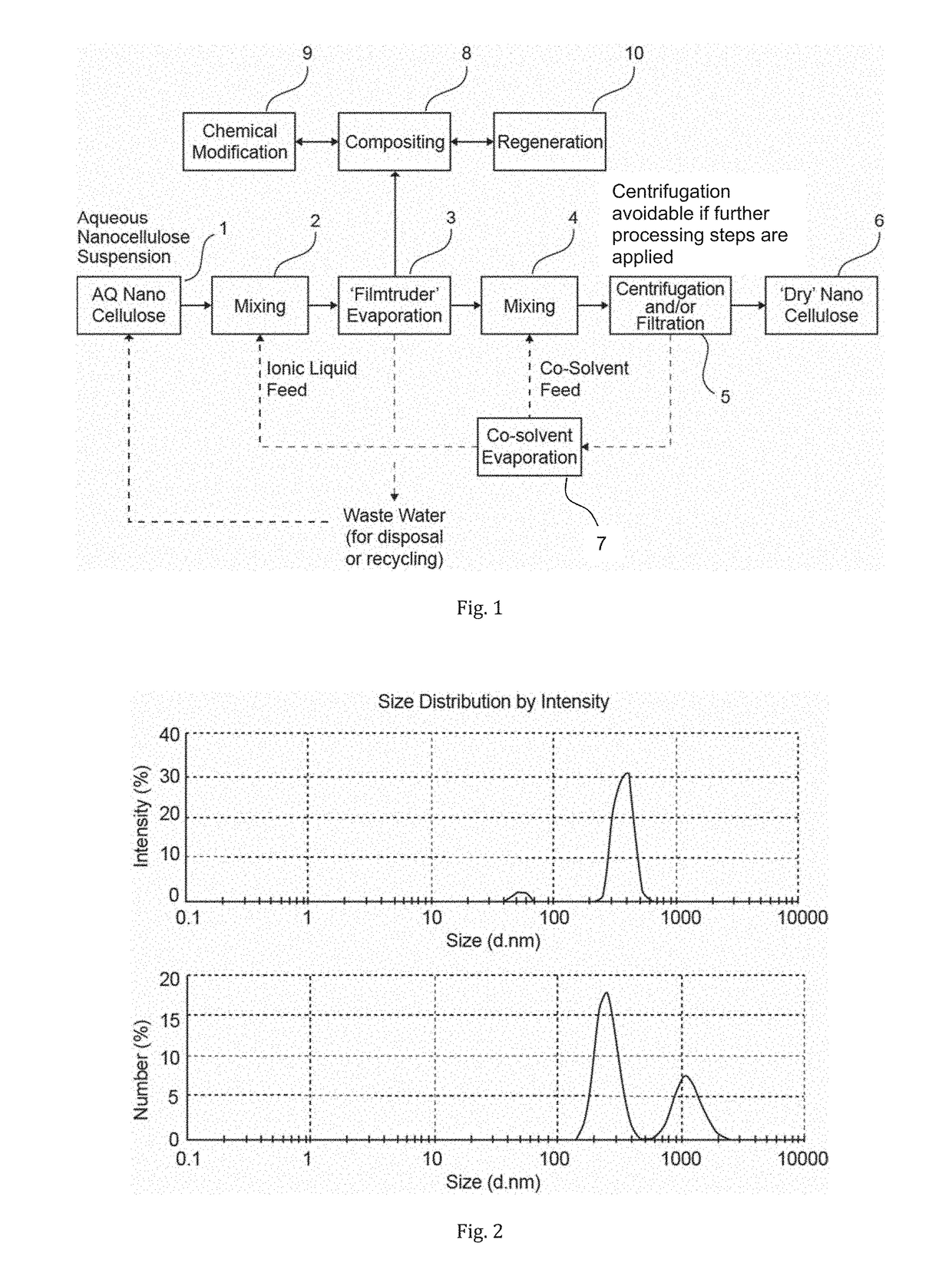

Method of dewatering water soluble polymers

InactiveUS20190023862A1Eliminate the problemReduced solvent consumptionPulp properties modificationPulp de-wateringHydrophilic polymersSolvent

Method of dewatering nanocellulose and other water soluble of hydrophilic polymers. The method comprises providing an aqueous suspension formed by nanocellulose in water, said nanocellulose having free hydroxyl groups; mixing the aqueous suspension with an ionic liquid or eutectic solvent which is capable of hydrogen bonding to at least a part of the free hydroxyl groups to form a modified suspension; and evaporating off water from the modified suspension in order to dewater the nanocellulose. With the ionic liquid procedure, solvent exchange with repeated centrifugation steps can be avoided, and solvent consumption and costs reduced, and processing sped up. The nanocellulose stabilized in the water-free environment then allows for access to efficient and thorough water-free chemical modification procedures resulting in highly fibrillated products.

Owner:UNIVERSITY OF HELSINKI

Apparatus for the semi-continuous chromatographic separation of binary and multi-component mixtures

InactiveUS20100230341A1Reduced solvent consumptionImprove productivityIon-exchange process apparatusComponent separationChromatographic separationChemistry

Owner:BAYER INTELLECTUAL PROPERTY GMBH

Reversed multiple leaching method for extracting rice bran crude oil

InactiveCN103834468AReduced solvent consumptionImprove the rate of improvementFatty-oils/fats productionEdible oils/fatsPelletizingBroken rice

The invention discloses a reversed multiple leaching method for extracting rice bran crude oil. The reversed multiple leaching method comprises the following process steps of (1) a pretreatment stage of the rice bran, comprising the steps of cleaning-pelletizing-drying; (2) a leaching stage comprising a leaching step; and (3) a separation stage of an oil phase and a solvent, comprising an evaporation step. The reversed multiple leaching method is characterized in that a broken rice separation step is arranged in the cleaning step of the pretreatment stage of the rice bran; a dust separation step is carried out on raw material grains after the drying step; and in the leaching stage, a reversed and continuous multiple leaching method is adopted. The reversed and continuous multiple leaching method lies in that a multi-shelf rice bran granular material frame is disposed in a leaching tank; and the rotation direction of the multi-shelf rice bran granular material frame is opposite to a solvent flow direction. In other words, the solvent firstly leaches the rice bran granular material in the last shelf, leaches the rice bran granular material in a plurality of shelves continuously in a reversed sequence and finally leaches the rice bran granular material in the first shelf. The method has the advantages of reducing solvent consumption rate, accelerating leaching speed, increasing oil yield and increasing the quality level of the rice bran crude oil.

Owner:JISHUI JINCHENG GRAIN & OIL

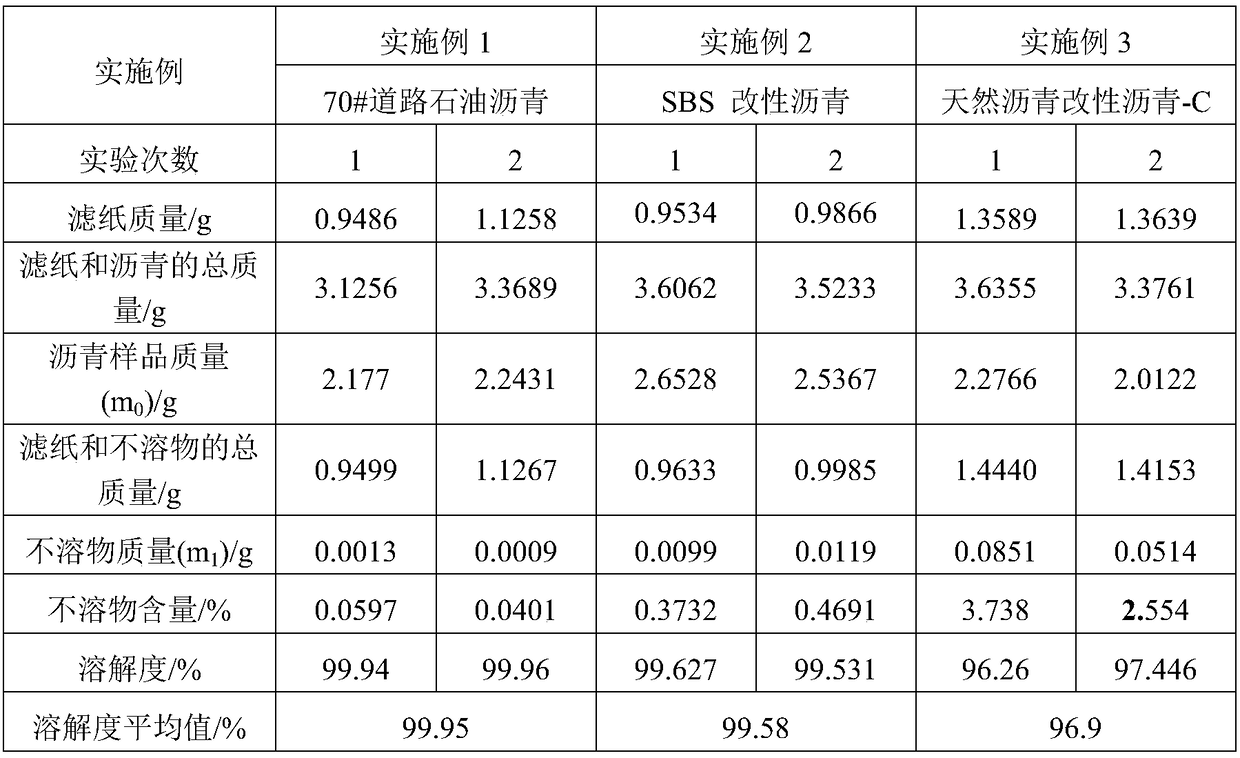

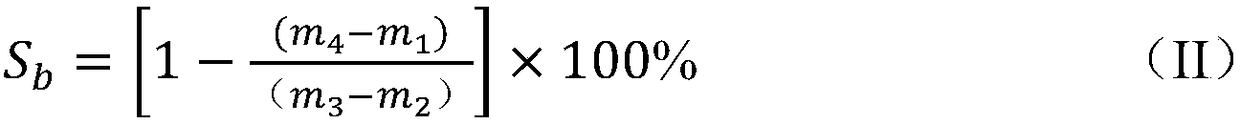

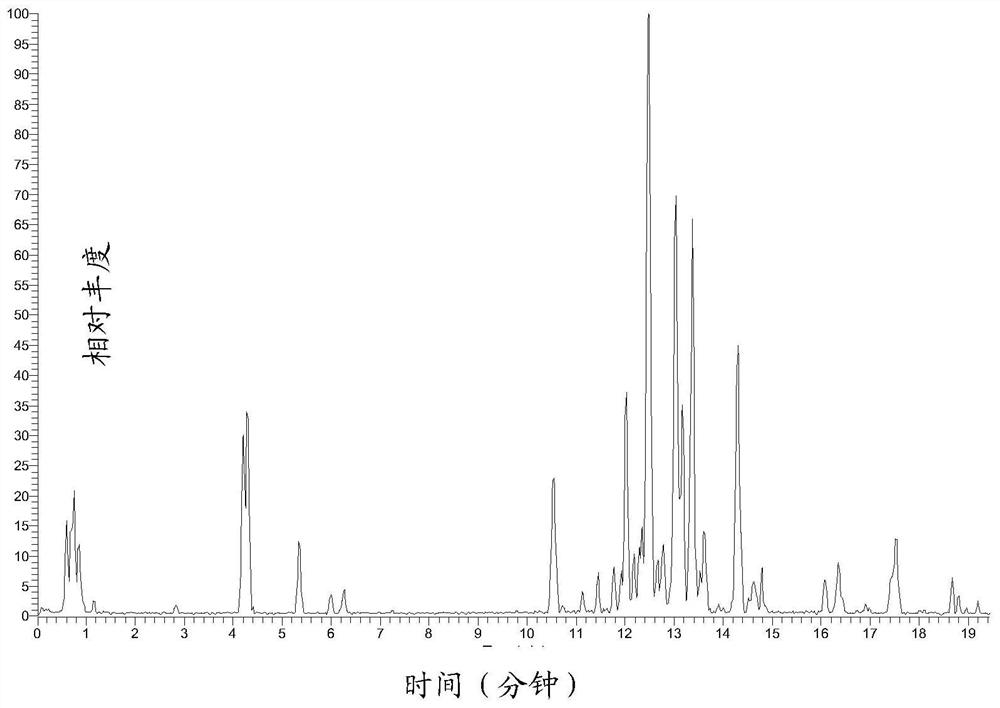

Asphalt solubility test method

ActiveCN109164008AImprove test productivityReduced solvent consumptionWeighing by removing componentEngineeringAsphalt

The invention relates to an asphalt solubility test method. The method comprises the following steps: 1, taking an asphalt sample, wrapping the asphalt sample by a filter device, and weighing the weights of the asphalt sample and the filter device; 2, soaking the filter device which wraps the asphalt sample in trichloro ethylene, and carrying out standing for the first time to ensure that the trichloro ethylene is in contact with the asphalt sample; 3, controlling the filter device which wraps the asphalt sample to periodically move in the trichloro ethylene, and removing the obtained asphaltdissolution solution; 4, retaking trichloro ethylene, soaking the filter device which wraps the asphalt sample in the trichloro ethylene to carry out periodical movement, carrying out standing for thesecond time, and removing the obtained dissolution solution; and 5, repeating the step 4 until the obtained asphalt solution is clear, obtaining filter devices with different insoluble substances, and obtaining weights of the insoluble substances to calculate solubility of the asphalt sample. The method provided by the invention is capable of effectively improving the working efficiency of the test.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Separation method of total ginsenosides

ActiveCN107693558BImprove adsorption capacityEasy to separatePlant ingredientsPhysical chemistryCarbon nanotube

The invention provides a method for separating total saponins of ginseng. The method comprises the following steps: adding ginseng powder into an extraction solvent, carrying out ultrasonic extractionunder the conditions of room temperature and normal pressure, then carrying out centrifugal separation, collecting liquid, and diluting the collected liquid with the extraction solvent so as to obtain a ginseng extracting solution; adding multi-walled carbon nanotubes into the ginseng extracting solution for adsorbing the total saponins, then carrying out centrifugal separation, and collecting solid; adding the solid into an elution solvent for eluting, then carrying out centrifugal separation, and collecting eluant to obtain the total saponins of the ginseng. The method provided by the invention has the advantages of high separation efficiency, short time consumption, less solvent consumption, simple operation and simple equipment.

Owner:JILIN YATAI PHARM CO LTD

Anti-glycation agent comprising a Garcinia kola extract or fraction

InactiveUS9107849B2Reduced solvent consumptionImprove solubilityOrganic active ingredientsCosmetic preparationsADAMTS ProteinsAnti glycation

An anti-glycation agent includes a Garcinia kola extract or fraction. The compositions including the extract or the fraction are used to inhibit the glycation of proteins, in particular the glycation of skin proteins involved in cutaneous aging. A method for determining the activity of compounds for inhibiting the glycation of cutaneous proteins, in particular for inhibiting the glycation of collagen is also described.

Owner:UNIV DANGERS +1

Purification method of polyamic acid resin and polyimide resin

ActiveUS8217135B2Efficient removalSimple processProcess efficiency improvementPolyamic acidPolymer chemistry

Purification methods of polyamic acid resin and polyimide resin are provided. The purification methods of polyamic acid resin or polyimide resin includes providing a polyamic acid resin or a polyimide resin containing metal ion impurities. Thereafter, a cation exchange resin is used to react with the polyamic acid resin or the polyimide resin in order to remove the metal ion impurities therein, and a water content in the polyamic acid resin or the polyimide resin is removed to purify the polyamic acid resin or polyimide resin.

Owner:DAXIN MATERIALS

Process for the Production of 4-Chloroacetoacetyl Chloride, 4-Chloroacetoacetic Acid Esters, Amides and Imides

ActiveUS20140039217A1Reduce dwell timeHigh yieldPreparation from carboxylic acid halidesOrganic compound preparationAcetic acidImide

The invention relates to process for the continuous production of 4-chloroacetoacetyl chloride, comprising the steps of (a) feeding diketene and chlorine into a thin film reactor and (b) reacting the diketene and chlorine to obtain 4-chloroacetoacetyl chloride. The invention also relates to a process for the production of 4-chloroacetoaceticacid ester, 4-chloroacetoaceticacid amide or 4-chloroacetoaceticacid imide from 4-chloroacetoacetyl chloride obtained according to the inventive process.

Owner:LONZA LTD

Solvent refining method for isocyanate prepared by phosgene method and devices used in same

ActiveUS9840462B2Simple processLow production costOrganic compound preparationSolid sorbent liquid separationPhysical chemistryHydrogen chloride

A solvent refining method for isocyanate prepared by the phosgene method and multistage absorbing towers used in same. Solvent to be refined which contains water, iron, and / or phosgene, hydrogen chloride and other materials with color is dealt by the present method and multistage absorbing towers, which can effectively prevent a drying agent from absorbing water and hardening, partial overheating in the tower and generating channeling. Meanwhile, the pressure drop is effectively lowered. In addition, the content of water is ≦50 ppm, the content of iron is ≦5 ppm, the content of phosgene and hydrogen chloride is ≦20 ppm, Pt—Co chroma is ≦20 in the refined solvent. Therefore, the refined solvent can be used as the solvent for preparing isocyanate in the phosgene method and remarkably improve an L color of isocyanate.

Owner:WANHUA CHEM GRP CO LTD

A chemical experiment extraction device

ActiveCN112516623BWell mixedImprove mixing efficiencyLiquid solutions solvent extractionEngineeringBottle

The invention provides a chemical experiment extraction device, comprising: a base, the two ends of which are vertically connected with fixed brackets; the driving part is arranged on the fixed bracket for providing power; the extraction reaction bottle is arranged rotatably at both ends On the two fixed brackets; the driving part can drive the extraction reaction bottle to rotate; the extraction reaction bottle includes: the first bottle body, which is provided with a liquid discharge port on the raised end; to the baffle; the first bottle and the second bottle are combined to form an extraction chamber; the end of the first bottle close to the fixed bracket is provided with a photoelectric sensor, and the base is provided with a receiver, which is arranged on the lower side of the photoelectric sensor , and corresponds to the position of the photoelectric sensor. The device rotates the extraction reaction bottle in the vertical direction, so that the multi-phase extraction liquid can be fully mixed, and the oblique baffle on the inner wall of the extraction reaction bottle helps to further promote the mixing of the liquid and improve the mixing efficiency.

Owner:SHAANXI SCI TECH UNIV

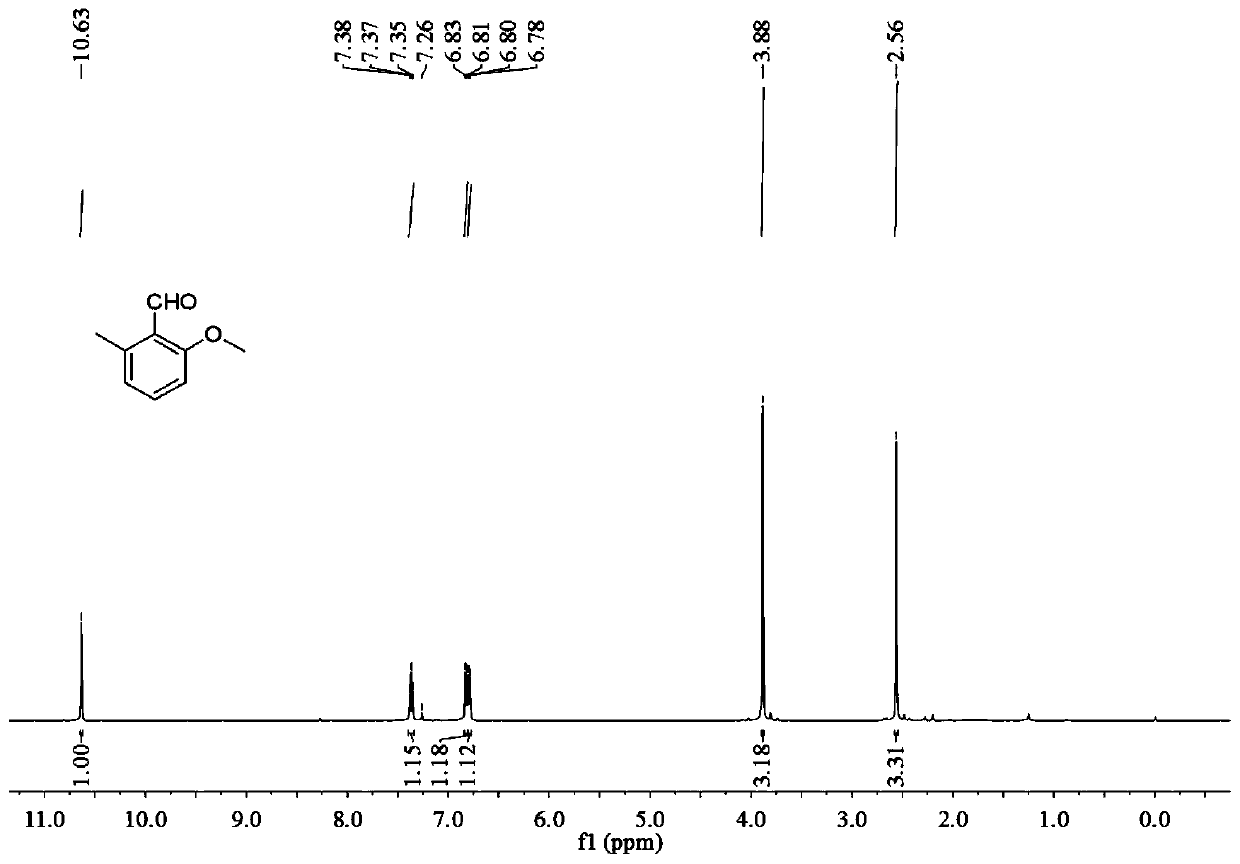

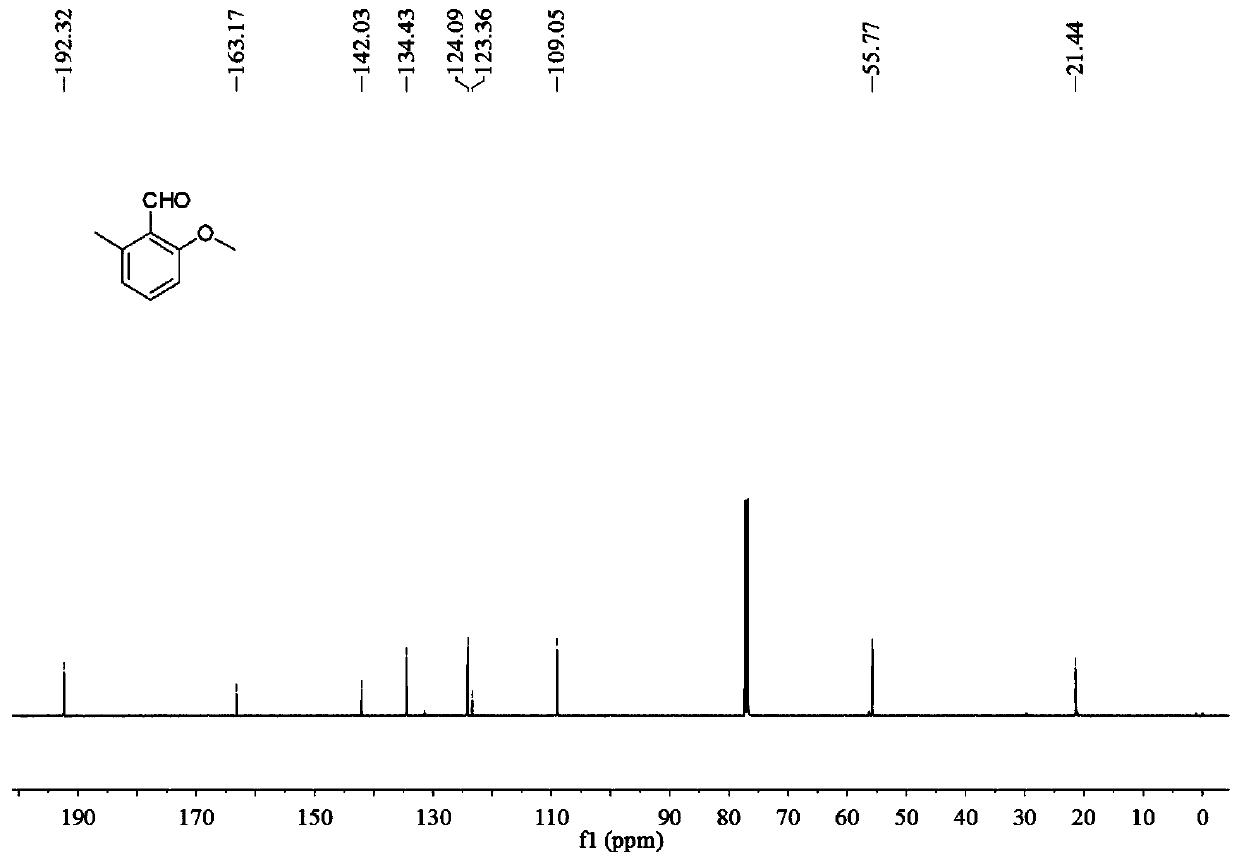

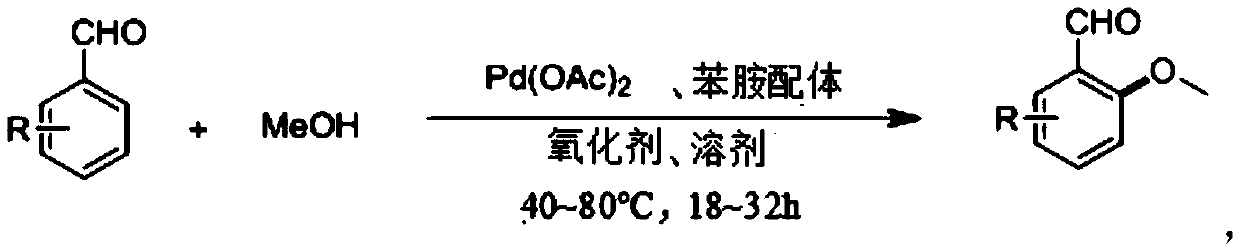

A kind of preparation method of o-methoxybenzaldehyde

ActiveCN110256217BHigh yieldHigh purityOrganic compound preparationCarbonyl compound separation/purificationWater methanolBenzaldehyde

The invention provides an o-methoxybenzaldehyde preparation method, which comprises: 1) mixing a benzaldehyde-based derivative, anhydrous methanol, palladium acetate, an oxidizing agent and an aniline ligand in a solvent, and carrying out a methoxylation reaction under a certain temperature condition to obtain a reaction liquid A; 2) filtering the reaction liquid A, and extracting the obtained filtrate B with an extractant to obtain a lower layer extracting liquid C; 3) drying the extracting liquid C with a drying agent to remove water, filtering, adding silica gel powder to the obtained filtrate D, and carrying out rotary evaporation to remove dichloromethane to obtain a mixture E; and 4) separating and purifying the mixture E through chromatography to obtain o-methoxybenzaldehyde. According to the present invention, the prepared o-methoxybenzaldehyde has high yield and high purity, wherein the yield can reach 67%; and the method has characteristics of simple preparation process, easy operation, short reaction time and substantially increased production efficiency.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com