Roadway maintenance machine for coal mine

A technology for repairing machines and roadways, which is applied in the field of excavators and roadway repairing machines for coal mines. It can solve problems such as low work efficiency, inability to work, and inconvenient operation, so as to improve work efficiency, facilitate operation angles, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is described in further detail:

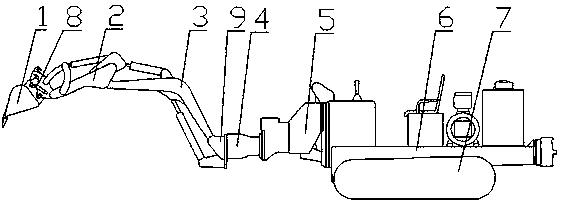

[0019] Such as figure 1 As shown, a coal mine roadway maintenance machine includes a car body part and an actuator, and the car body part includes a traveling device 7 and a vehicle frame 6 installed above the traveling device 7 . The vehicle frame 6 is equipped with a driver's seat, an operating console, an engine that provides power for the traveling device 7 and the hydraulic cylinder, and the like. The actuator includes a boom 3, a small arm 2 and a bucket 1. One end 5 of the boom 3 is installed on the front end of the frame 6, and the end of the boom 3 away from the frame 6 is connected to the end of the small arm 2, and the small arm 2 is far away from the One end of the boom 3 is equipped with a bucket 1 . A hydraulic cylinder driving the movement of the forearm 2 is installed above the boom 3 , and a hydraulic cylinder driving the movement of the boom 3 is installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com